Photosensitive resin composition, cured product thereof, and printed circuit board

A photosensitive resin and composition technology, applied in printed circuit parts, epoxy coatings, optics, etc., can solve problems such as through-hole floating, coating film overflow, shortening working time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

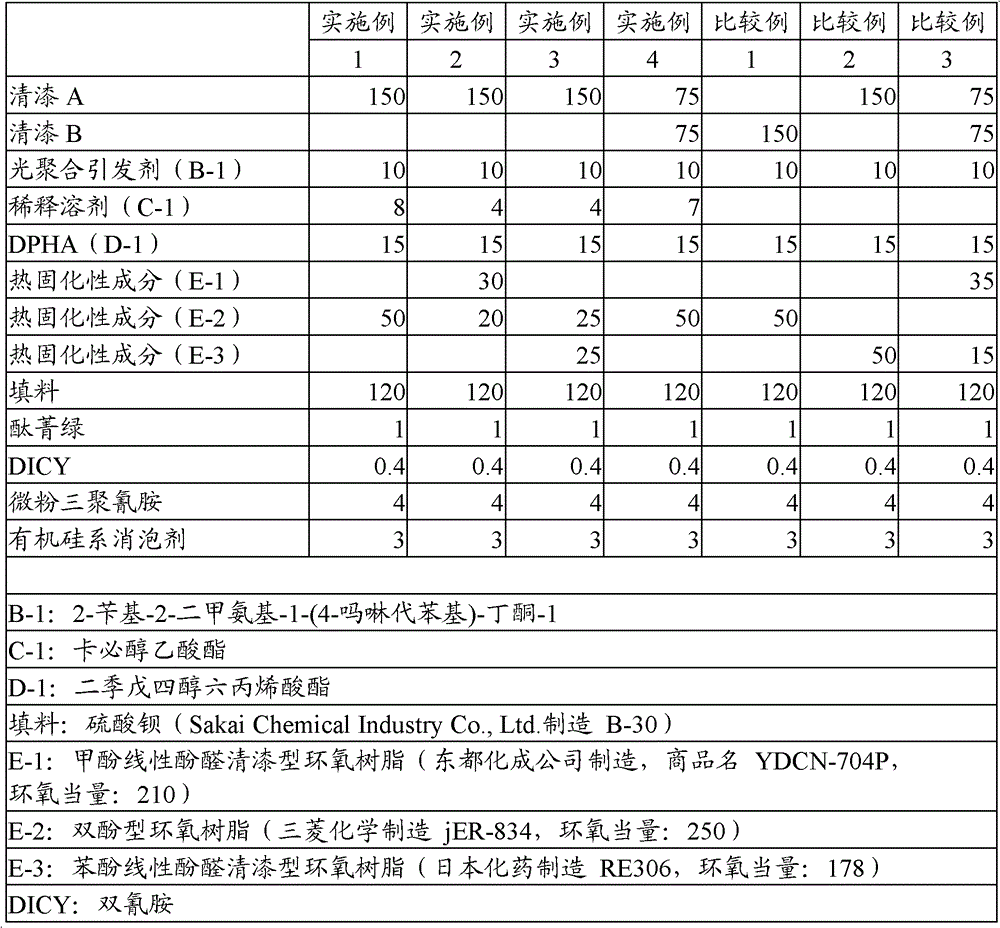

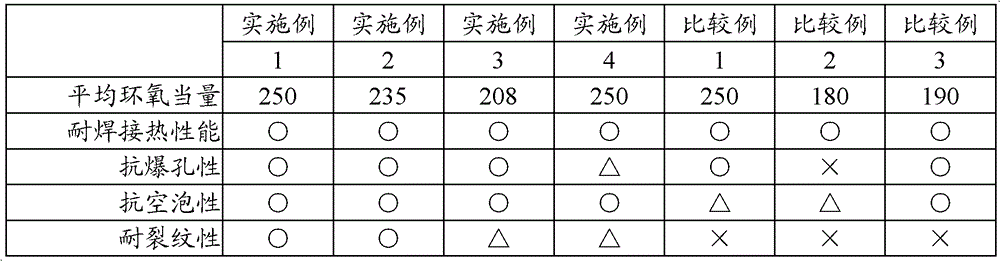

Examples

Synthetic example 1

[0094] 86 parts of 1,4-cyclohexanedicarboxylic acid and 378 parts of Bisphenol A epoxy resin (Mitsubishi Chemical Corporation make, EPIKOTE828, epoxy equivalent: 189 g / equivalent) was dissolved at 110°C with stirring in a nitrogen atmosphere. Thereafter, 0.3 parts of triphenylphosphine was added, the temperature in the reaction container was raised to 150° C., and the reaction was carried out for about 90 minutes while maintaining the temperature at 150° C. to obtain an epoxy compound having an epoxy equivalent of 464 g / equivalent. Next, cool the temperature in the flask to 40°C, add 390 parts of carbitol acetate, heat to dissolve, add 0.46 parts of methylhydroquinone and 1.38 parts of triphenylphosphine, heat to 95-105°C, slowly drop 72 parts of acrylic acid, reacted for 16 hours. The reaction product was cooled to 80-90° C., 190 parts of tetrahydrophthalic anhydride was added, and reacted for 8 hours. The carboxyl group-containing photosensitive resin thus obtained had a n...

Synthetic example 2

[0096] 214 parts of EPICLONN-695 of cresol novolak type epoxy resin (manufactured by Dainippon Ink Chemical Industry Co., Ltd., epoxy equivalent=214) are put into a four-necked flask with a stirrer and a reflux condenser, and 103 parts of carbites are added. Alcohol acetate and 103 parts of petroleum-based hydrocarbon solvents (trade name: Cactus Fine SF-01 manufactured by Japan Energy Corporation) were heated and dissolved. Next, 0.1 part of hydroquinone as a polymerization inhibitor and 2.0 parts of triphenylphosphine as a reaction catalyst were added. The mixture was heated to 95-105°C, 72 parts of acrylic acid was slowly added dropwise, and reacted for 16 hours. Cool the obtained reaction product to 80-90°C, add 91.2 parts of tetrahydrophthalic anhydride, react for 8 hours, take it out after cooling. The carboxyl group-containing photopolymerizable unsaturated compound thus obtained had a nonvolatile content of 65%, and an acid value of solid matter of 87.5 mgKOH / g. Here...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com