Eccentric ball valve with liner and preparation method thereof

An eccentric ball and lining technology, which is applied in valve details, valve device, valve shell structure, etc., can solve the problems that the shape is sometimes granular, sometimes liquid, the price of the valve remains high, and the temperature changes with a large range. Shorten the assembly cycle, overcome poor sealing, and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

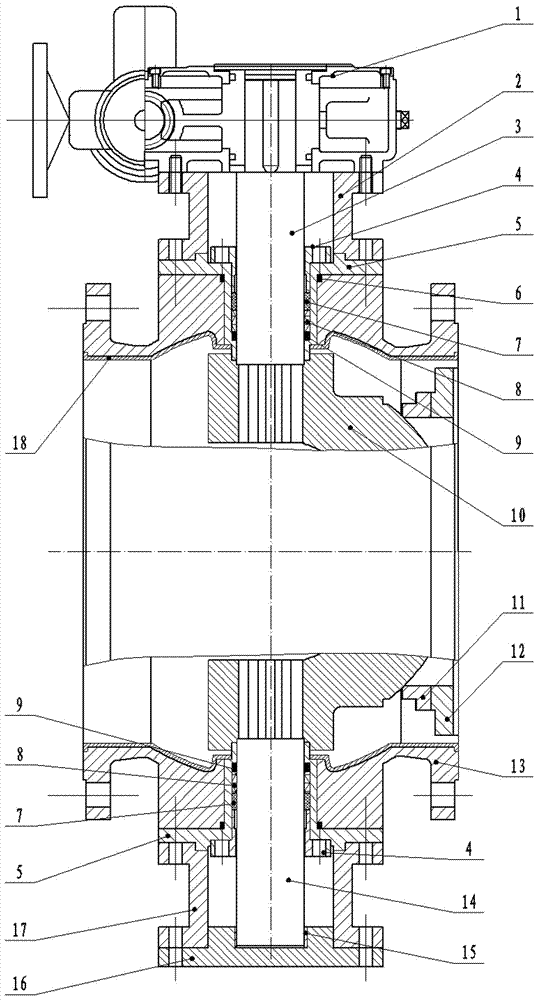

[0057] The preparation method of described valve body 13 comprises the following steps:

[0058] In the first step, the liner 18 is precision casted using an alloy material by using an investment casting method, and the alloy material is stainless steel, titanium alloy, copper alloy, or iron-manganese alloy.

[0059] The second step is to passivate the lining layer 18 after casting the lining layer 18 .

[0060] In the third step, after passivating the lining layer 18, a layer of ceramic paint is applied on the outside thereof, and the thickness of the ceramic paint is 0.1-3 mm.

[0061] The fourth step is to heat the lining layer 18 coated with the ceramic paint to 250-350°C.

[0062] The fifth step is to put the above-mentioned treated liner 18 into a sand mold made of water glass as pre-embedding, and pour the outer layer material quickly, and the outer layer material is made of carbon steel or ductile iron.

[0063] Step 6: Cool the liner 18 quickly after pouring, and le...

Embodiment 1

[0077] First prepare high-temperature resistant ceramic coatings, synthesize aluminum hydroxide or aluminum oxide with phosphoric acid, use phosphoric acid solution with a weight concentration of 85% and aluminum hydroxide powder to react and synthesize in liquid phase, and the reaction temperature is 110-130°C to obtain phosphoric acid Aluminum dihydrogen, then according to the following proportioning by weight:

[0078] 44-48 parts of kaolin, 20-50 parts of modified epoxy resin, 10-30 parts of quartz powder, 7-8 parts of acetone, 6-7 parts of aluminum dihydrogen phosphate and 3-5 parts of polyurethane powder to prepare high-temperature resistant ceramics coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com