Apparatus for photoreaction

A photoreaction and reaction technology, applied in laser devices, measuring devices, lasers, etc., can solve the problems of low density, difficult photoreaction, and low reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

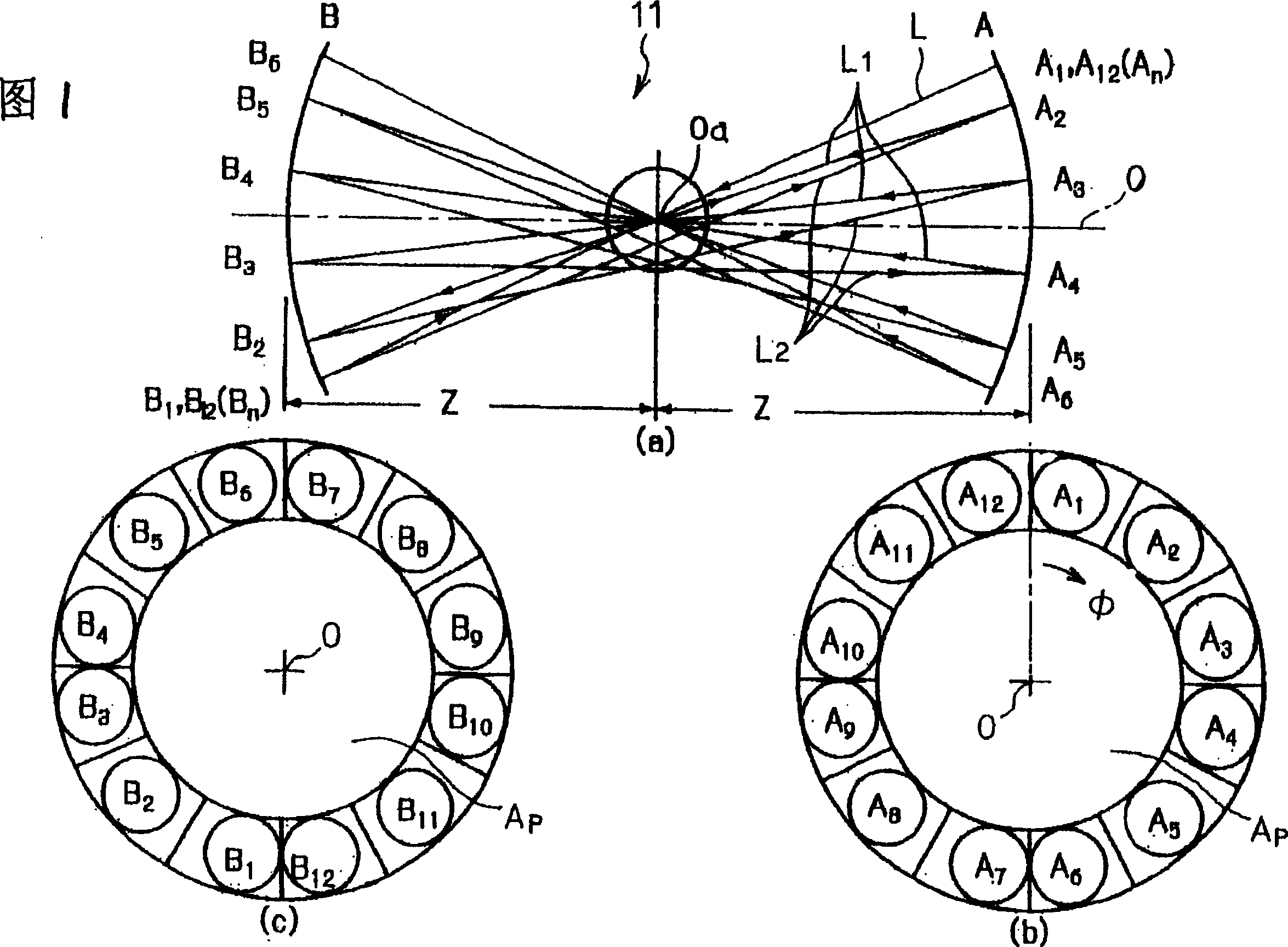

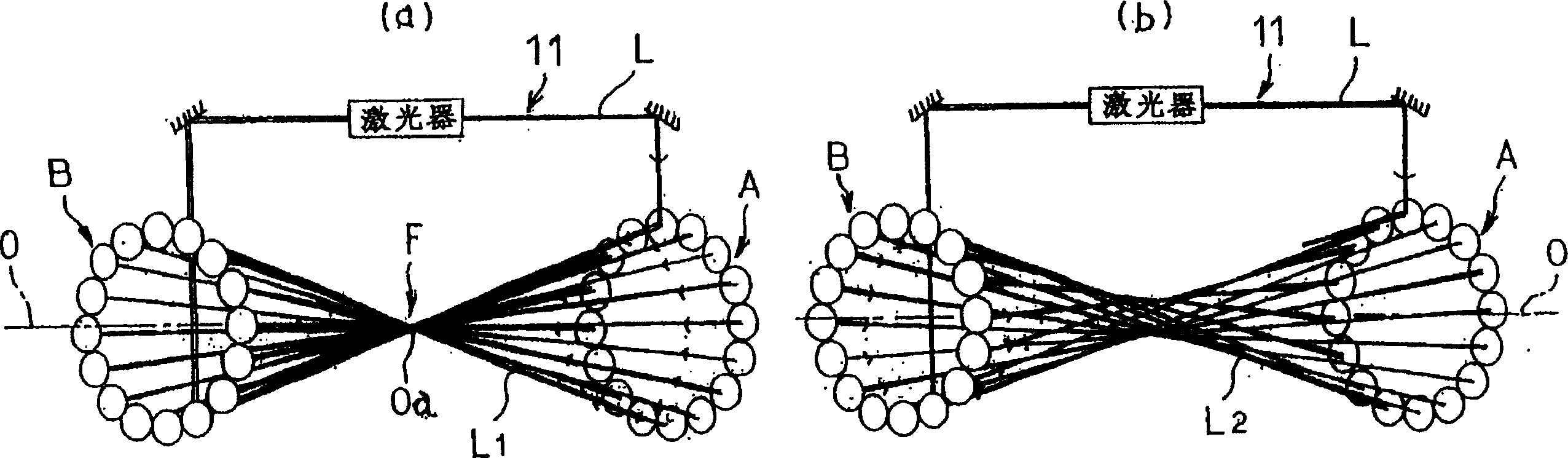

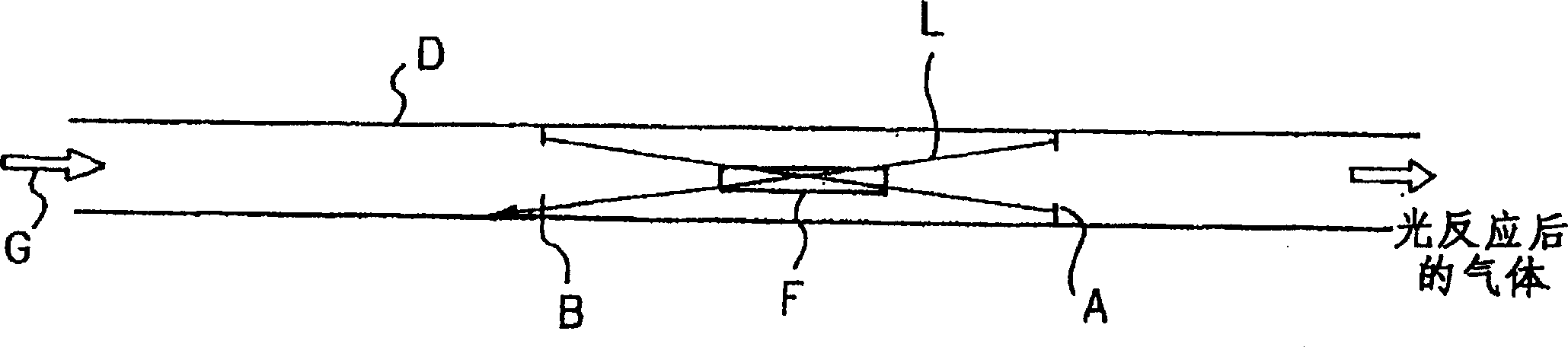

[0017] Embodiments of the present invention will be described with reference to the drawings. Fig. 1 is a diagram showing an overview of the photoreaction device of the present invention, (a) is a side view, and (b) and (c) are front views of respective mirror groups. figure 2 The optical paths L1 and L2 of the laser beams passing between the mirror groups A and B are shown.

[0018] The photoreaction device 11 has a pair of mirror groups A, B placed opposite to each other. The mirror group A is formed by arranging a plurality of concave mirrors A1, A2, . . . , An in a ring around the axis O. The mirror group B is formed by arranging a plurality of concave mirrors B1 , B2 , . . . , Bn in a ring around the axis O. FIG. 1 shows a case where mirror groups A and B each consist of 12 concave mirrors (in the case of n=12). An opening Ap for introducing electron beams is formed inside the rings of the mirror groups A and B. As shown in FIG. In Fig. 1(a), it shows that the mirror ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com