Method and device for cleaning depositinon jet head

A technology of ejection head and equipment, applied in the directions of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of increasing production costs, increasing the probability of damage to separators, and taking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]The present invention relates to a method and equipment for cleaning a deposition ejection head, which can be applied to a chemical vapor deposition machine for depositing silicon-containing oxides. The silicon-containing oxides are currently used in semiconductor materials including BPSG (Boron-phosphorous Silicon Dioxide) , BSG (Boron Silicon Dioxide), PSG (Phosphorous Silicon Dioxide), USG (Undoping Silicon Dioxide) and NSG (Non-doping Silicon Dioxide), and the chemical vapor deposition machine for depositing the silicon-containing oxide can be atmospheric pressure chemical vapor deposition ( Atmosphere Chemical Vapor Deposition) machine and sub-atmospheric chemical vapor deposition (Sub-atmosphere Chemical Vapor Deposition) machine.

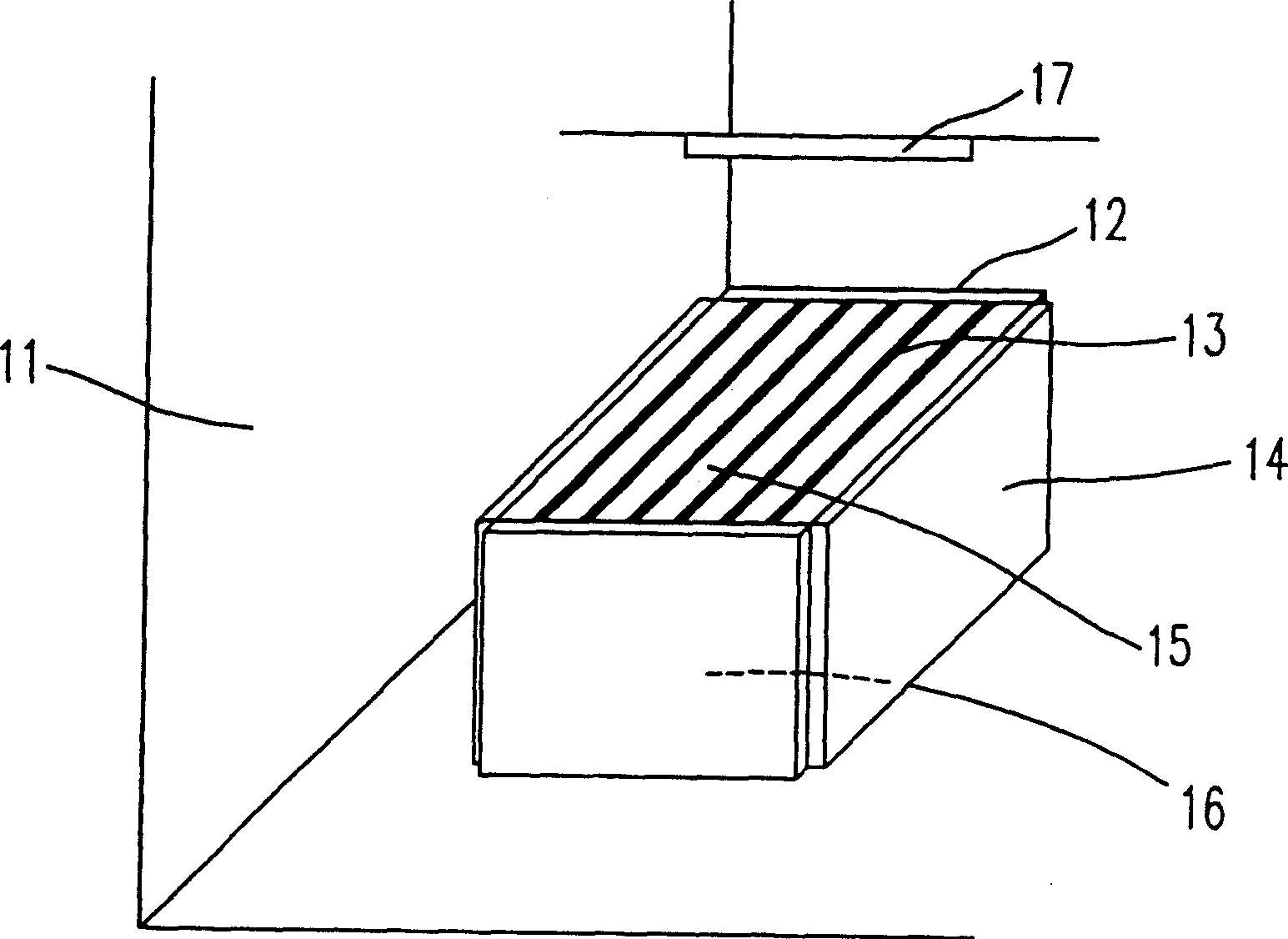

[0055] For a better understanding of the invention of the present invention for cleaning a chemical vapor deposition ejection head, see figure 1 , which is a chemical vapor deposition machine structure. Since the chemical vapor deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com