Method for preparing zirconium oxide hollow ceramic mahjong

A technology of zirconia ceramics and hollow ceramics, applied in zirconia, ceramic molding machines, manufacturing tools, etc., can solve the problems of zirconia ceramics, such as large specific gravity, heavy weight, unsuitable for entertainment, etc., to achieve crisp sound, light weight, color and luster. rounded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

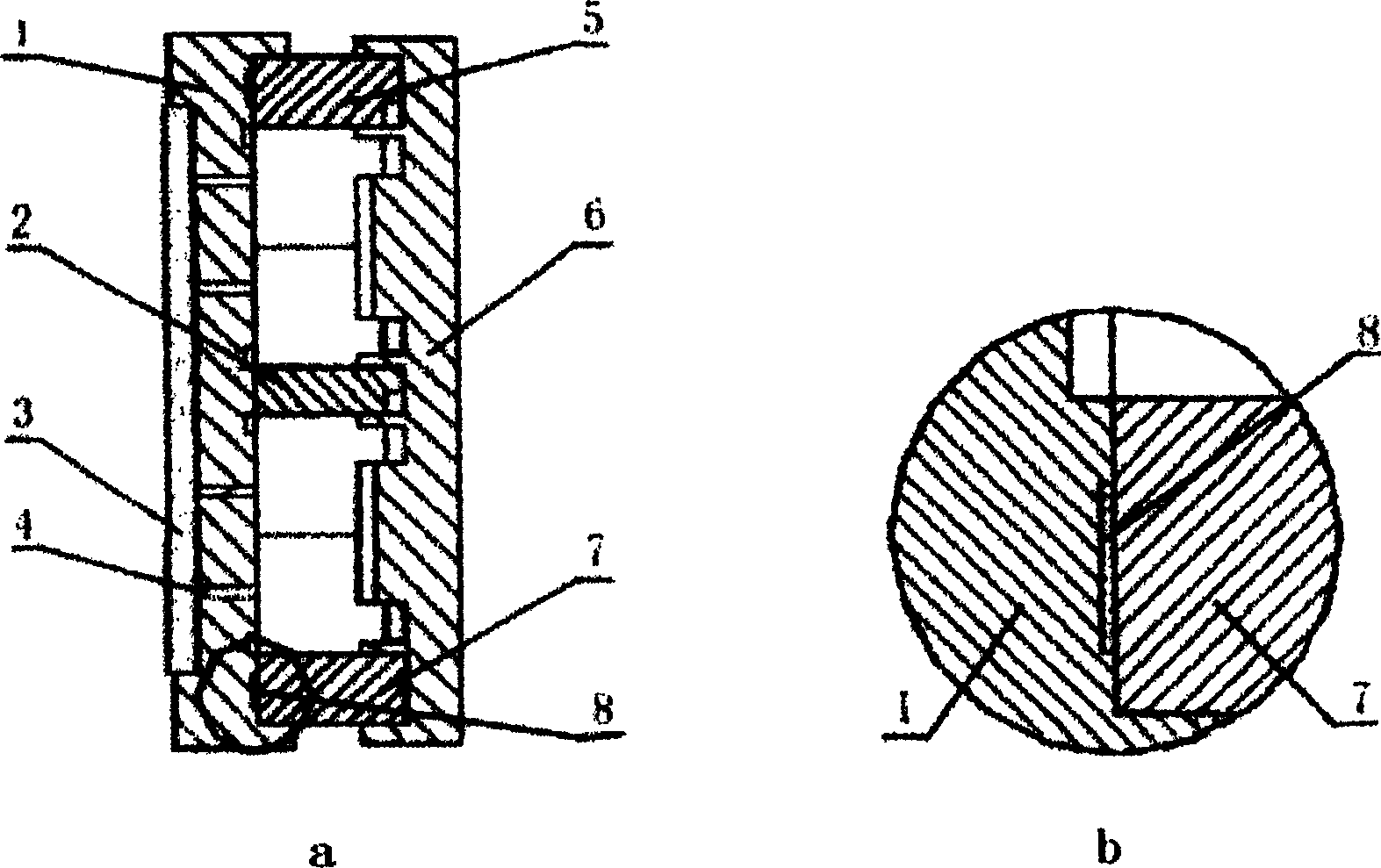

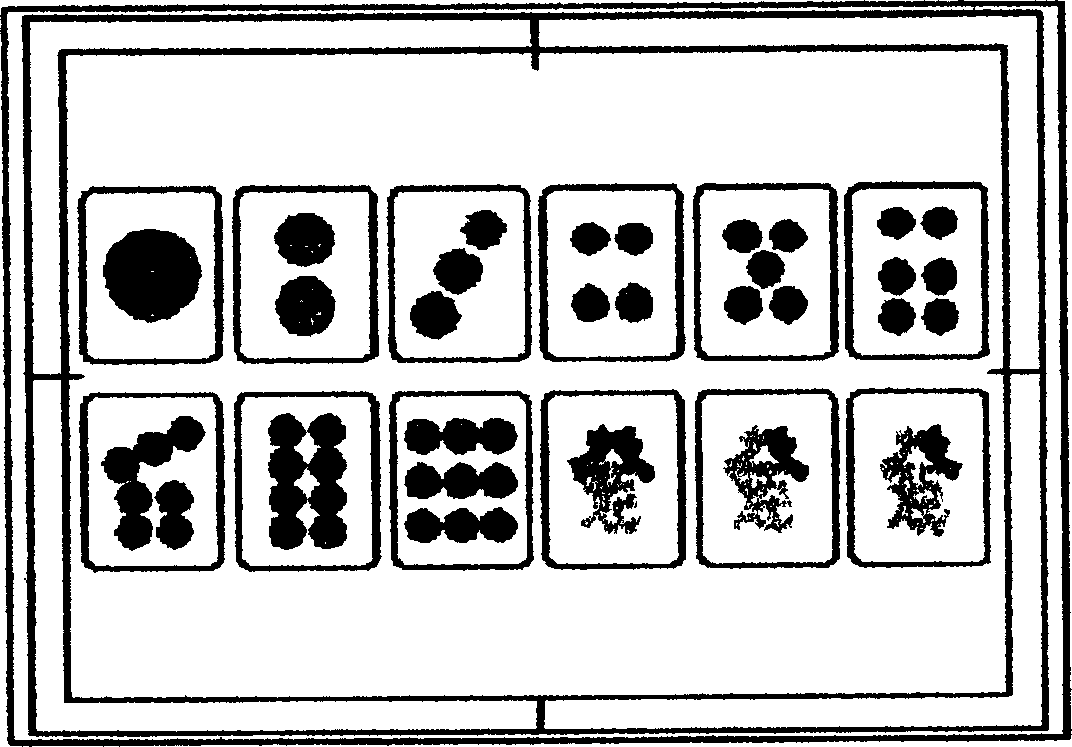

[0042] Take TZP-Tetragonal ZrO 2 Polycrystalline ceramic powder, the powder particle size is about 70nm; CeO 2 As a stabilizer, the content is 12mol% (or Y 2 o 3 As a stabilizer, Y 2 o 3 The content is 2mol%, or CeO 2 / Y 2 o 3 As a composite stabilizer, the content is generally 10mol%, CeO 2 / Y 2 o 3 ratio is 8), in deionized water to prepare a premix solution containing 20wt% hydroxyethyl acrylate monomer and methylenebisacrylamide, the ratio of methylenebisacrylamide and hydroxyethyl acrylate is 1:30, Ball milled for 24 hours to obtain a 35vol% ceramic slurry. 0.12 ml of ammonium persulfate was added to 100 ml of the slurry, and the slurry was poured into a metal mold. A prefabricated rectangular paraffin block mold core is placed in the mold, and the paraffin block is surrounded and solidified when the ceramic slurry fills the mold. Then put it into a degreasing furnace at 120° C. to remove the glue, and at the same time, the paraffin block melts and is discharg...

Embodiment 2

[0044] Take the cubic phase ZrO 2 Ceramic powder, the particle size of the powder is about 50nm, the content of CaO is generally 6mol%, and it is used as a stabilizer, (or Y 2 o 3 content of 8 mol% or MgO content of 14 mol%). Prepare a premix solution containing 32wt% of hydroxyethyl acrylate monomer and methylenebisacrylamide in deionized water, the ratio of methylenebisacrylamide and hydroxyethyl acrylate is 1:25, and ball mill for 24 hours to obtain 33vol % ceramic slurry. Add 0.2ml of ammonium persulfate to 100ml of slurry, inject the slurry into a metal mold through colloidal injection molding, and the injection pressure is 2MPa. A prefabricated rectangular paraffin block mold core is placed in the mold, and the paraffin block is surrounded and solidified when the ceramic slurry fills the mold. Then put it into a degreasing furnace at 120° C. to remove the glue, and at the same time, the paraffin block melts and is discharged from the wax outlet to obtain a hollow cer...

Embodiment 3

[0046] Partially stabilized ZrO in the PSZ 2 MgO is added into the ceramic powder as a stabilizer, and the content of MgO is 9 mol% (or CaO is used as a stabilizer, and the content of CaO is 12 mol%). Prepare a premix solution containing 20wt% of hydroxyethyl acrylate monomer and methylenebisacrylamide in deionized water, the ratio of methylenebisacrylamide and hydroxyethyl acrylate is 1:30, and ball mill for 24 hours to obtain 45vol % ceramic slurry. 0.12 ml of ammonium persulfate was added to 100 ml of the slurry, and the slurry was poured into a metal mold. A prefabricated rectangular paraffin block mold core is placed in the mold, and the paraffin block is surrounded and solidified when the ceramic slurry fills the mold. Then put it into a degreasing furnace at 120° C. to remove the glue, and at the same time, the paraffin block melts and is discharged from the wax outlet to obtain a hollow ceramic mahjong body. The hollow body was sintered at 1600°C for 1.5h to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com