Method for mfg. high voltage element

A technology of high-voltage components and manufacturing methods, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problem that the breakdown voltage of high-voltage components cannot be effectively increased, and achieve the effect of increasing the value of the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

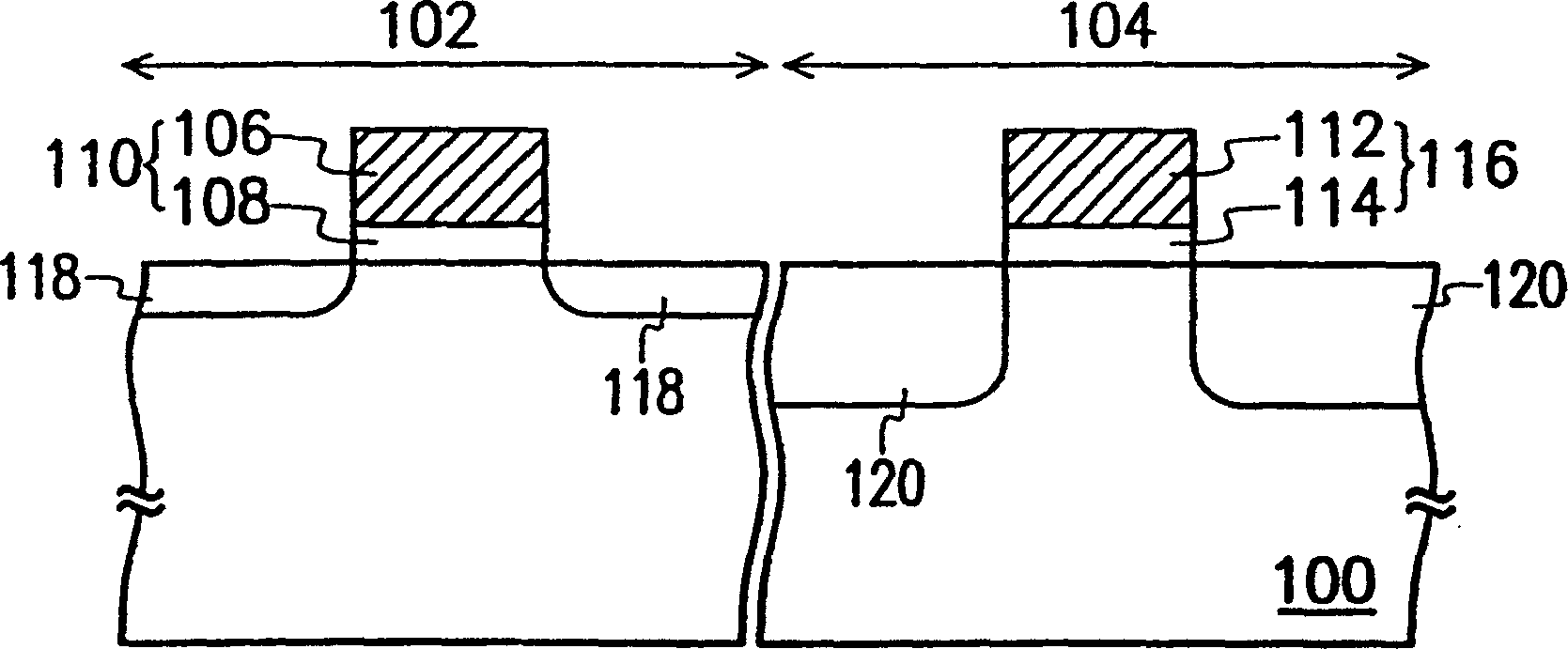

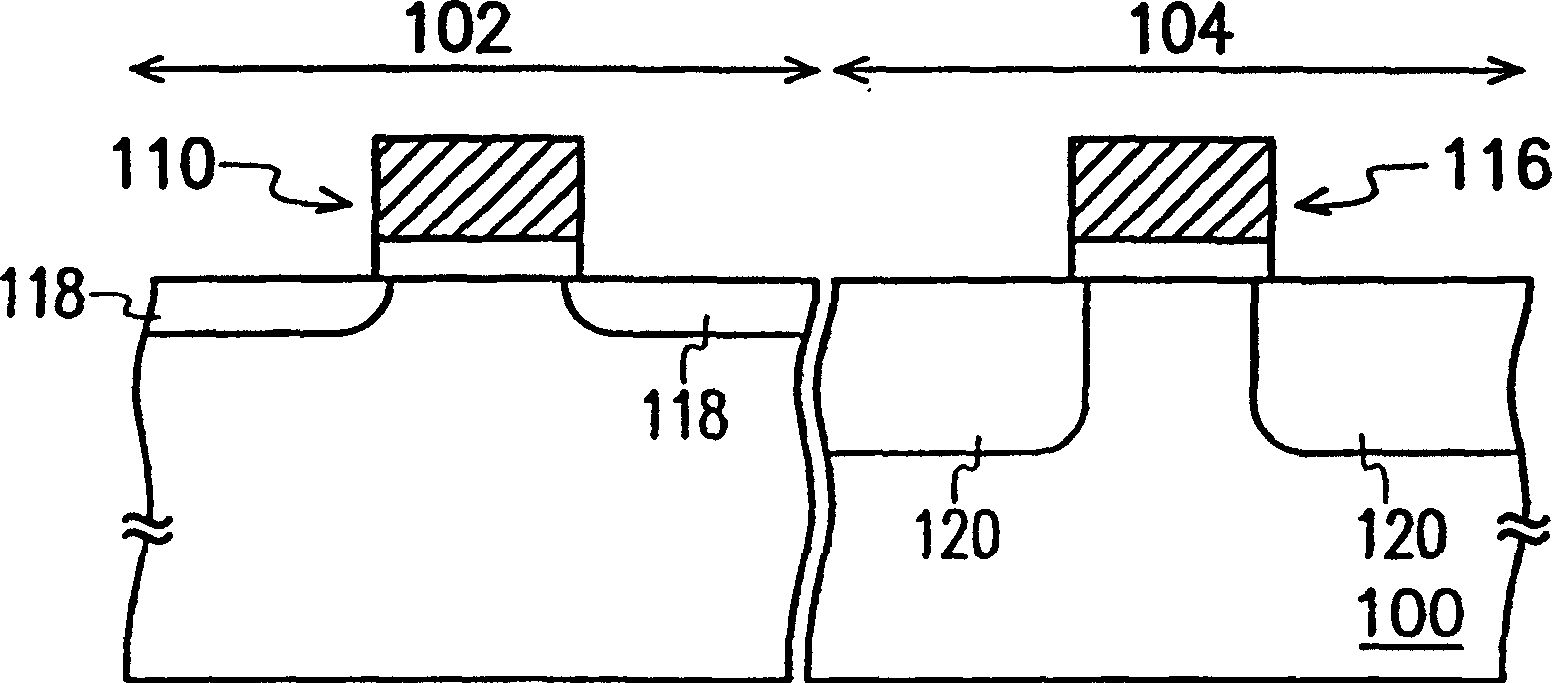

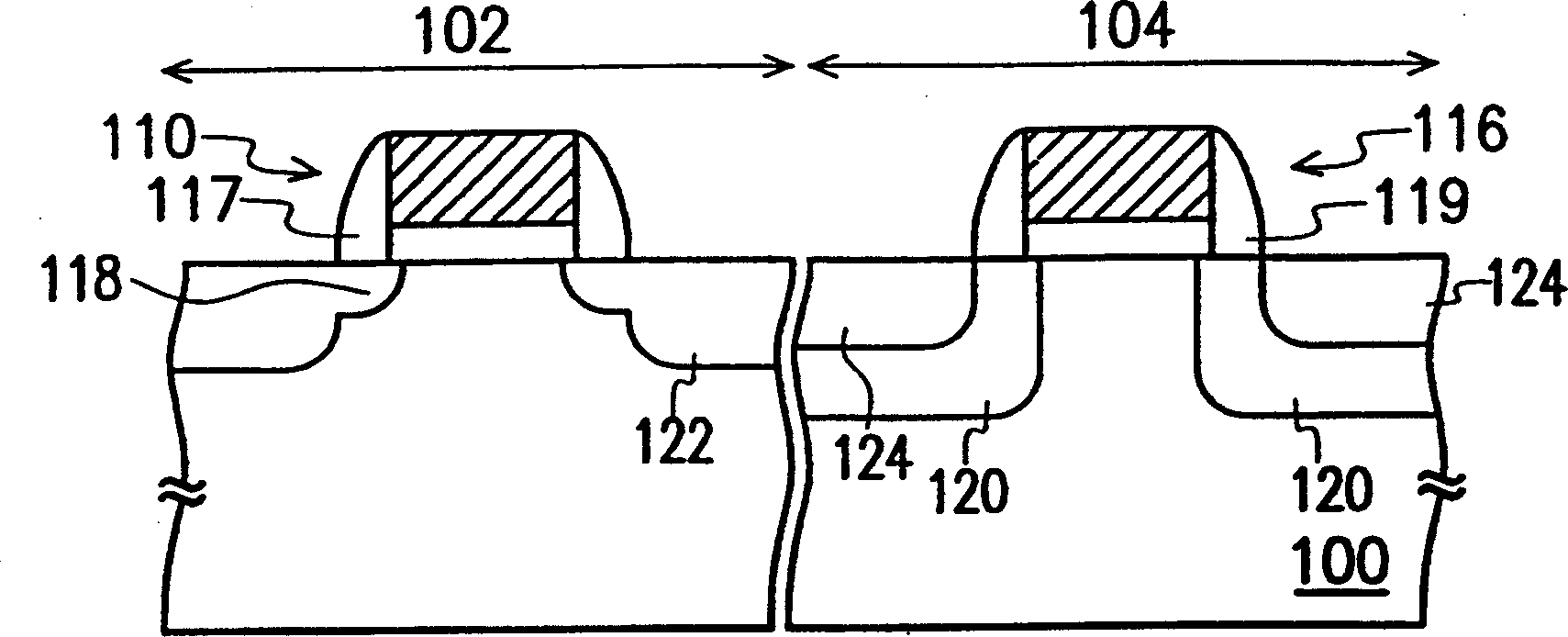

[0029] Figure 2A to Figure 2E , which is a schematic cross-sectional view of the manufacturing process of a high-voltage element according to a preferred embodiment of the present invention.

[0030] Please refer to Figure 2A Firstly, a substrate 200 is provided, wherein the substrate 200 has a general device region 202 and a high voltage device region 204 . Next, a gate structure 210 and 216 are respectively formed on the normal device region 202 and the high voltage device region. Wherein, the gate structure 210 , 216 includes a gate conductive layer 206 , 212 and a gate oxide layer 208 , 214 . The material of the gate conductive layers 210 and 216 is, for example, polysilicon.

[0031] After that, please refer to Figure 2B A lightly doped drain region (LDD) 218 is formed in the substrate 200 on both sides of the gate structure 210 in the general device region 202 . Next, a first thermal process is performed. The first thermal process is a tempering step performed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com