Lid seal for cylindrical containers

A technology for sealing cylindrical cans and caps, which is applied to bottle/container caps, capping containers with caps, applications, etc. It can solve problems such as damage to the sealing machine, achieve reliable sealing effects, reduce production costs, and reliable sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0024] In different drawings, the same part is represented by the same symbol.

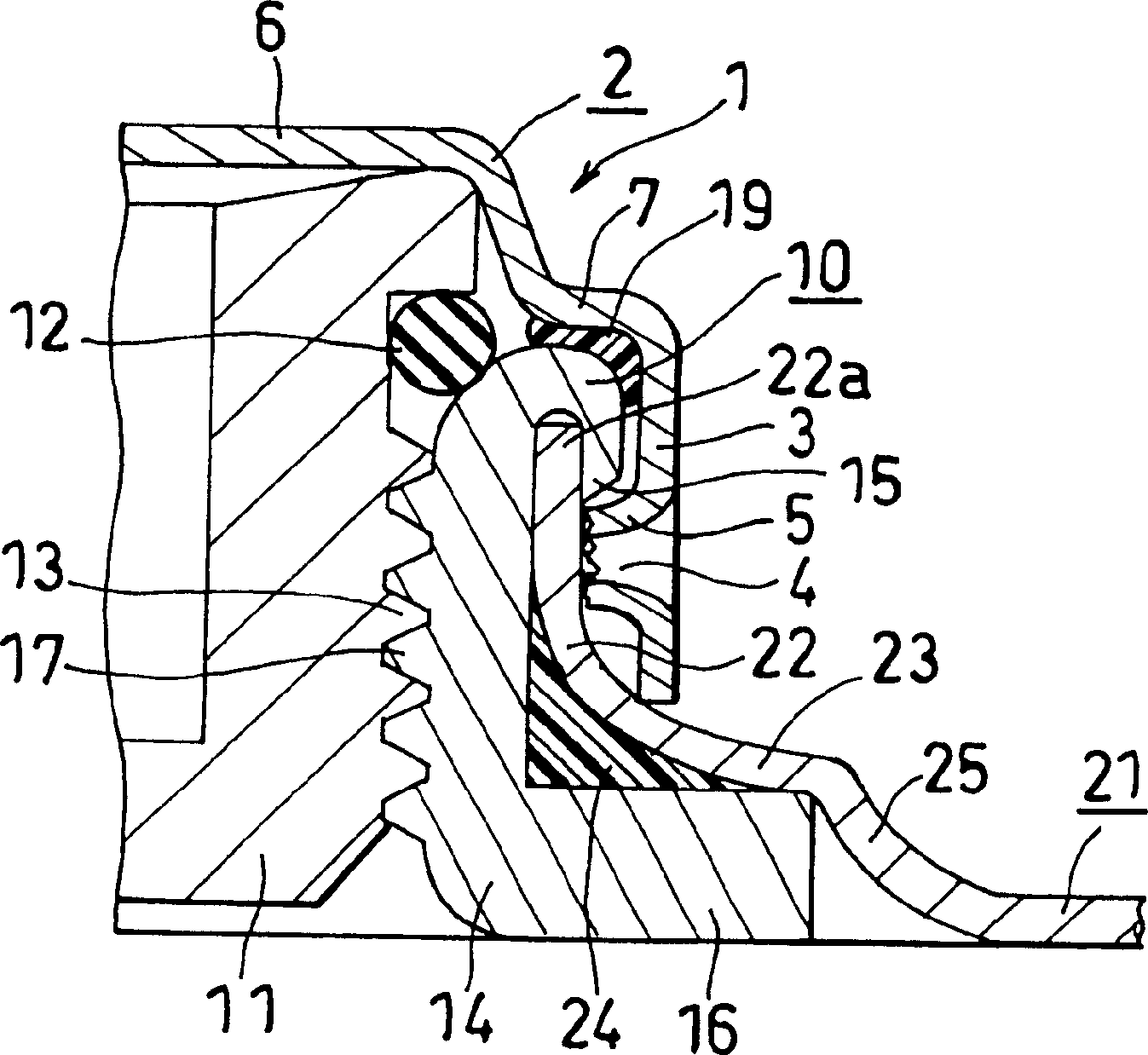

[0025] Figure 1~ Figure 4 It is used to explain the first embodiment of the present invention. In addition, usually on the top (21) of the cylindrical tank, there are two large mouthpieces (10) of different sizes, one large and one small, or the same size, but the one shown in this embodiment is a larger mouthpiece. Department (10).

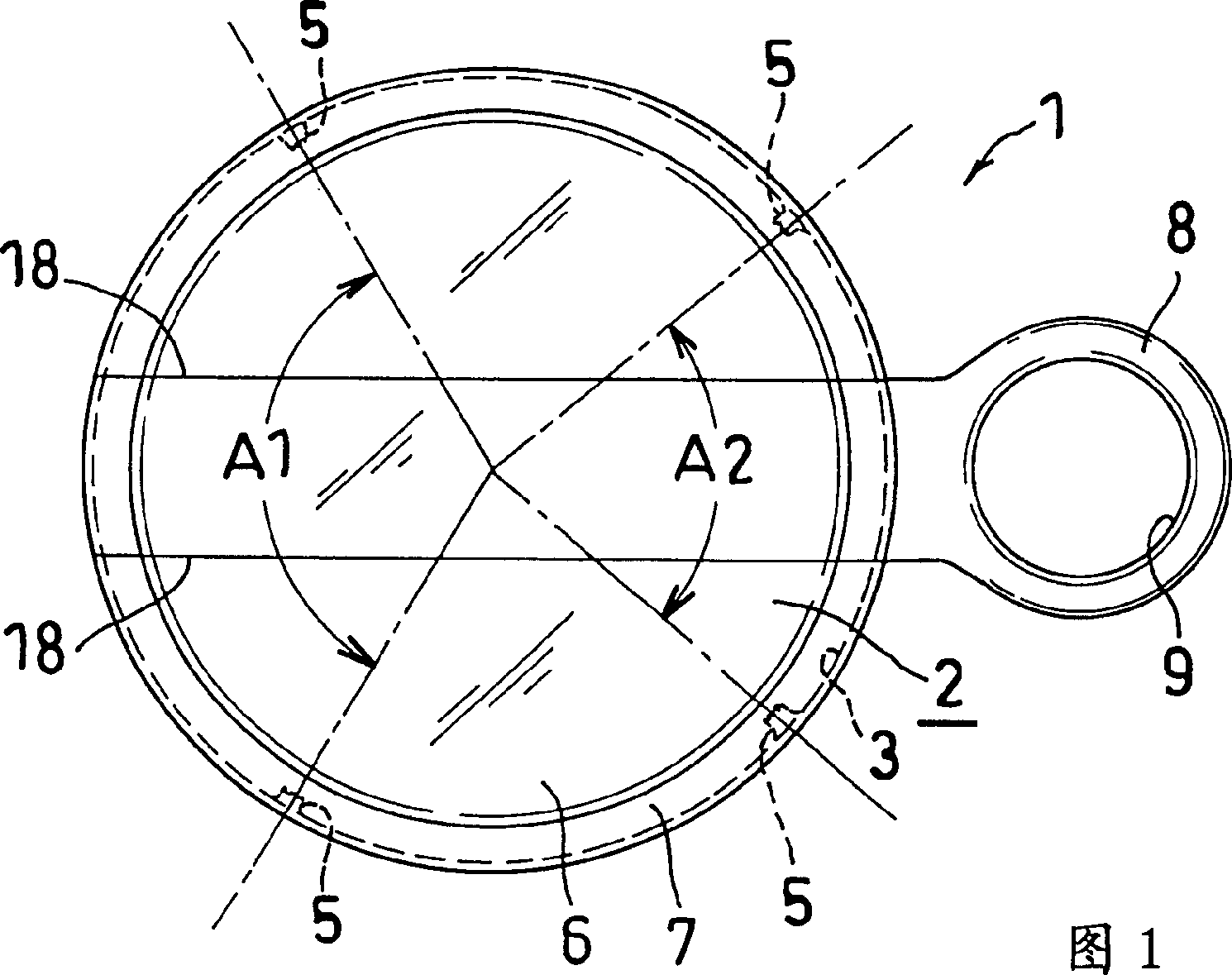

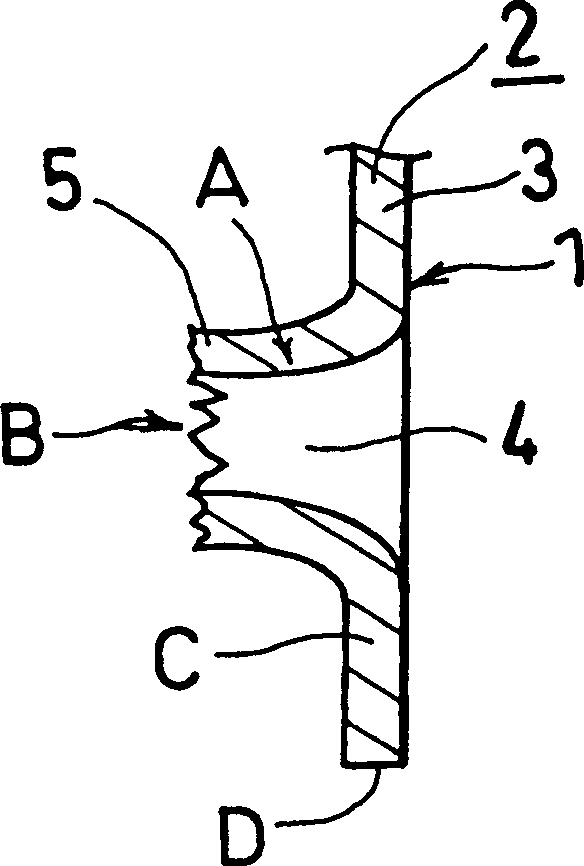

[0026] As shown in Figure 1, according to the present invention, the cover seal (1) is provided with a through hole (4) and a ring-shaped serrated protrusion (5), wherein the through hole (4) is set on an iron plate with a thickness of 0.2 At four places on the pendant peripheral wall (3) of the peripheral edge of the sealing body (2) that is 0.4 mm in height and circular in plan view, ring-shaped serrated protrusions (5) are located on the peripheral edge of the through hole (4). The diameter of the portion protruding toward the inner side of the cover sealing b...

no. 2 approach

[0049] Figure 6 It is used to illustrate the second embodiment of the lid seal (1) in the present invention. Here, the difference from the above-mentioned first embodiment lies in the number and distribution of the ring-shaped zigzag protrusions (5).

[0050] That is, nine annular serrated protrusions (5) are provided on the drooping peripheral wall (3) of the peripheral edge of the cover body (2). And on the part of the pendant peripheral wall (3) on the opposite side of the unsealing handle (8) on one side of the lid seal body (2), an annular sawtooth-shaped protrusion (5) is provided. Near the part (8) and on both sides of the notch (18) (18) used for tearing the lid seal, spaced apart from each other at a distance of about 80° angle (A2), each is provided with a pair of two ring-shaped sawtooth-shaped protrusions. (5)(5), on the opposite side of the handle portion (8) for unsealing and spaced apart from each other at a distance of about 120° angle (A1), each pair of 2 r...

no. 3 approach

[0052] Figure 7 It is used to describe the third embodiment of the lid seal (1) in the present invention. Here, the difference from the above-mentioned first embodiment is that the lid seal (1) is mounted on the small mouthpiece (10) of the top (21) of the cylindrical tank, and is in the shape of a pendant on the periphery of the lid seal body (2). Three ring-shaped zigzag protrusions (5) are arranged on the peripheral wall (3).

[0053] That is, two ring-shaped serrated protrusions (5) located near the unsealing handle (8a) on one side of the lidding body (2) and on both sides of the notch (18) (18) for tearing the lidding )(5), separated by a distance of about 80° angle (A2), and the two ring-shaped serrated protrusions (5)(5) and the one on the opposite side of the handle (8a) There is a distance of about 140° angle (A3) between one ring-shaped sawtooth-shaped protrusions (5). In this way, when the cap seal (1) is assembled at the small mouthpiece (10) of the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com