Wire bunch wiring structure for piggyback pod

A wiring structure and power cabin technology, applied in the direction of upper structure, power device, upper structure sub-assembly, etc., can solve the problems of increasing production cost and reducing assembly work efficiency, and achieve the effect of improving work efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, an embodiment of the present invention will be described in detail together with the accompanying drawings.

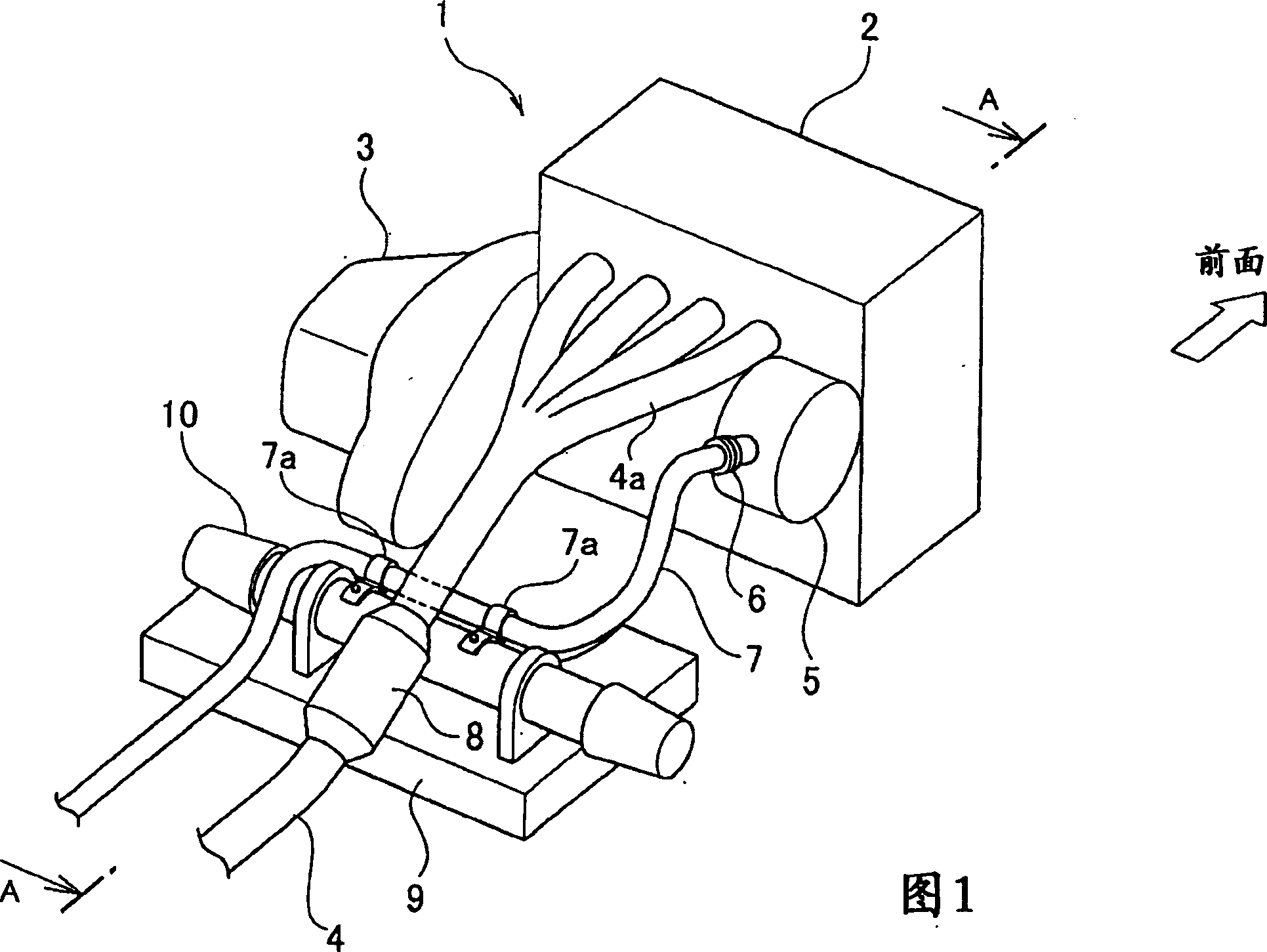

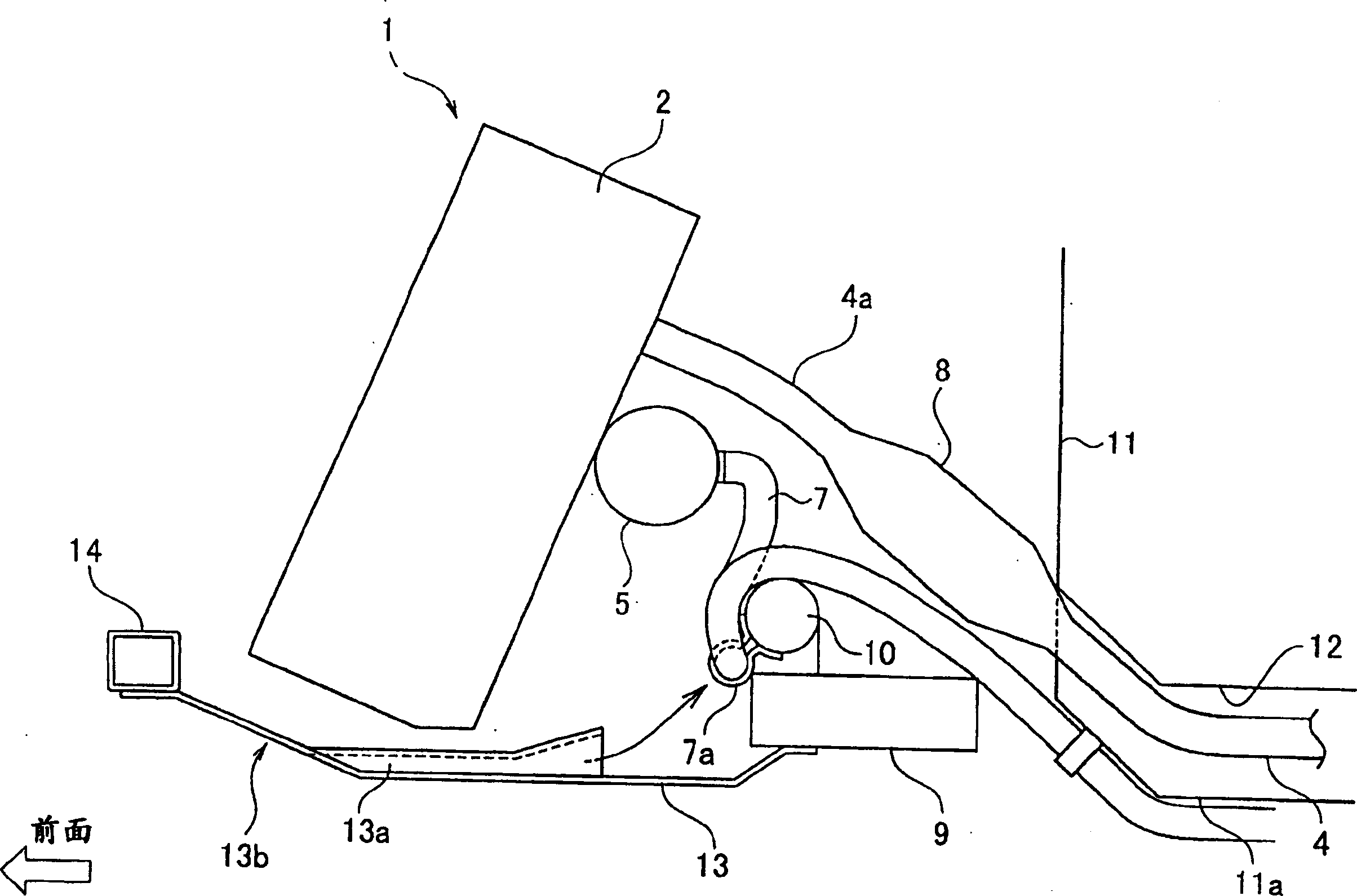

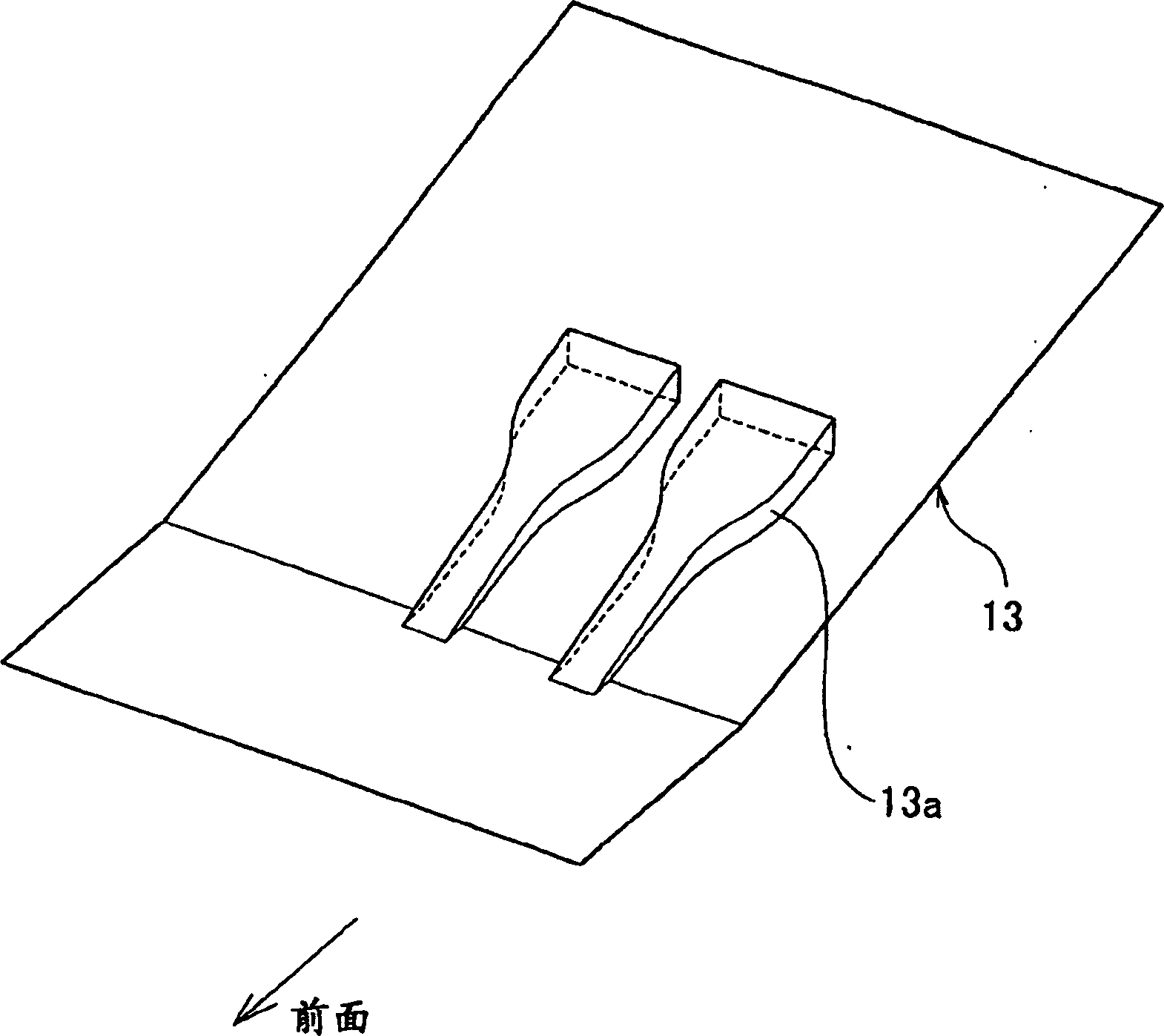

[0015] Figure 1~ image 3 Shown is an embodiment of the wire harness wiring structure of the power cabin of the present invention, and Fig. 1 is a brief structural diagram of the power cabin applying the present invention, figure 2 It is a sectional view cut along the arrow A-A of Fig. 1, image 3 is to zoom in figure 2 A perspective view showing the main parts.

[0016] In Figure 1 and figure 2 Among them, 1 represents the entire powertrain, between a pair of front side parts not shown extending in the front and rear directions of the vehicle body on both sides of the vehicle width direction, through The bracket portion shown in FIG.

[0017] On the engine body 2, an exhaust manifold 4a for exhausting is connected to the rear side, and the exhaust pipe 4 connected to the exhaust manifold 4a through the catalyst 8 passes through the instrument ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com