Open spinning appst. having air static force radial bearing for spinning rotor

A technology of starting spinning and radial bearing, applied in air cushion bearings, free-end spinning machines, bearings, etc., it can solve the problems of aerostatic radial bearings being damaged and unusable, and achieve high mechanical bearing capacity and small friction. Coefficient, the effect of reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

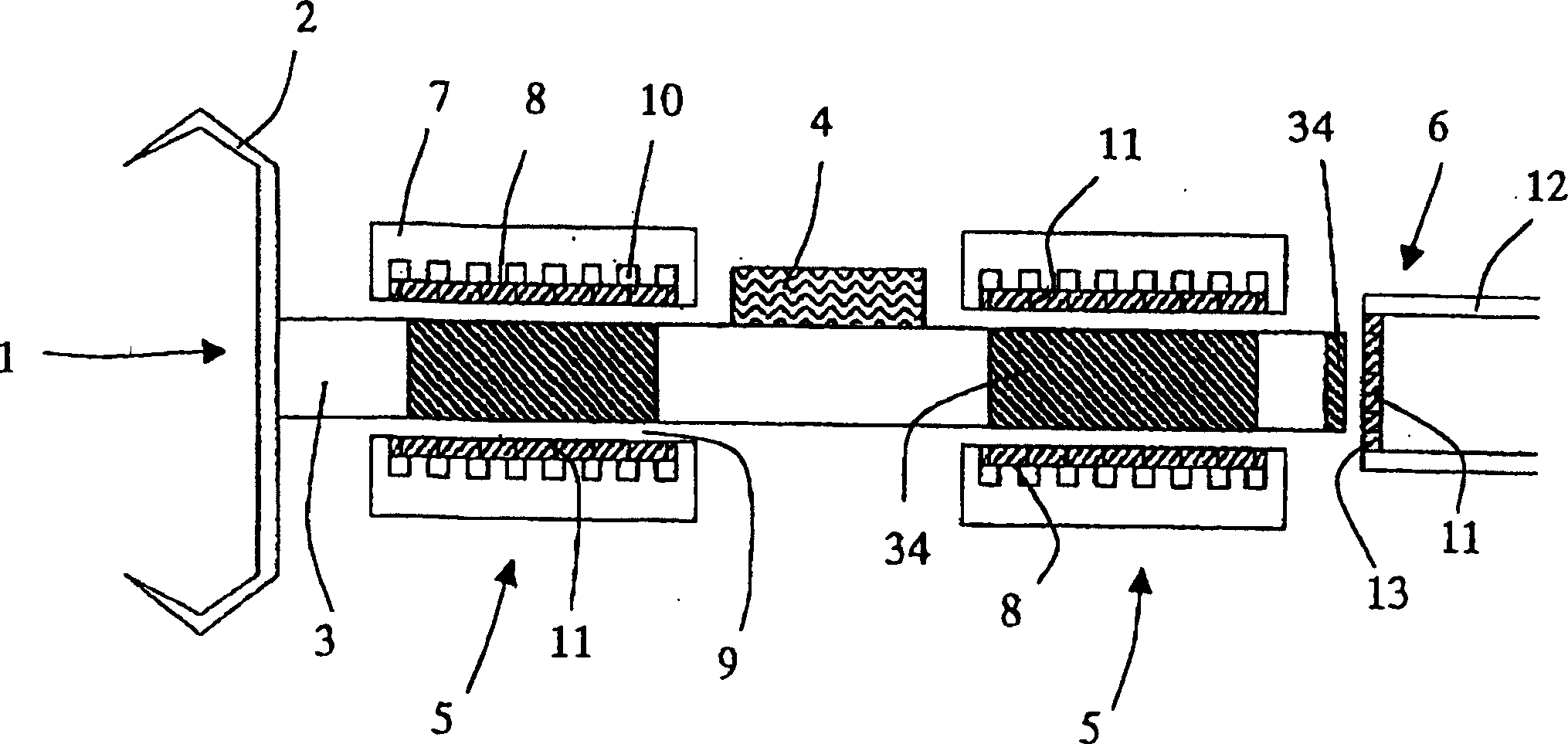

[0020] figure 1 Shown is a spinning rotor 1 with a rotor disk 2 and a shaft 3 for an open-end spinning device. The shaft 3 is moved in rotation by a tangential drive belt 4 running on the shaft 3 . The shaft 3 is radially supported by two identical radial bearings 5 , while the axial support of one end face is realized by an axial bearing 6 mounted on the end of the shaft 3 opposite to the rotor disk 2 .

[0021] exist figure 1 In the illustrated embodiment of the rotor shaft bearing, the axial forces acting in the direction of the axial bearing 6 are transmitted by a slightly inclined drive belt 4 running on the shaft 3 . Wherein the transmission belt 4 is not at an angle of 90° to the axis of the shaft 3 but runs at a very small angle. exist figure 1 The rotation of the shaft 3 shown in for example enters the drawing plane with its top and turns outwards from the drawing plane with its bottom part, like this, the drive belt 4 that is straight to the drawing plane direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com