Catalytic cracking process for preparing high-grade gasoline

A gasoline and heavy gasoline technology, applied in catalytic cracking, cracking, petroleum industry, etc., to improve gasoline quality, reduce cracking reactions, and improve desulfurization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

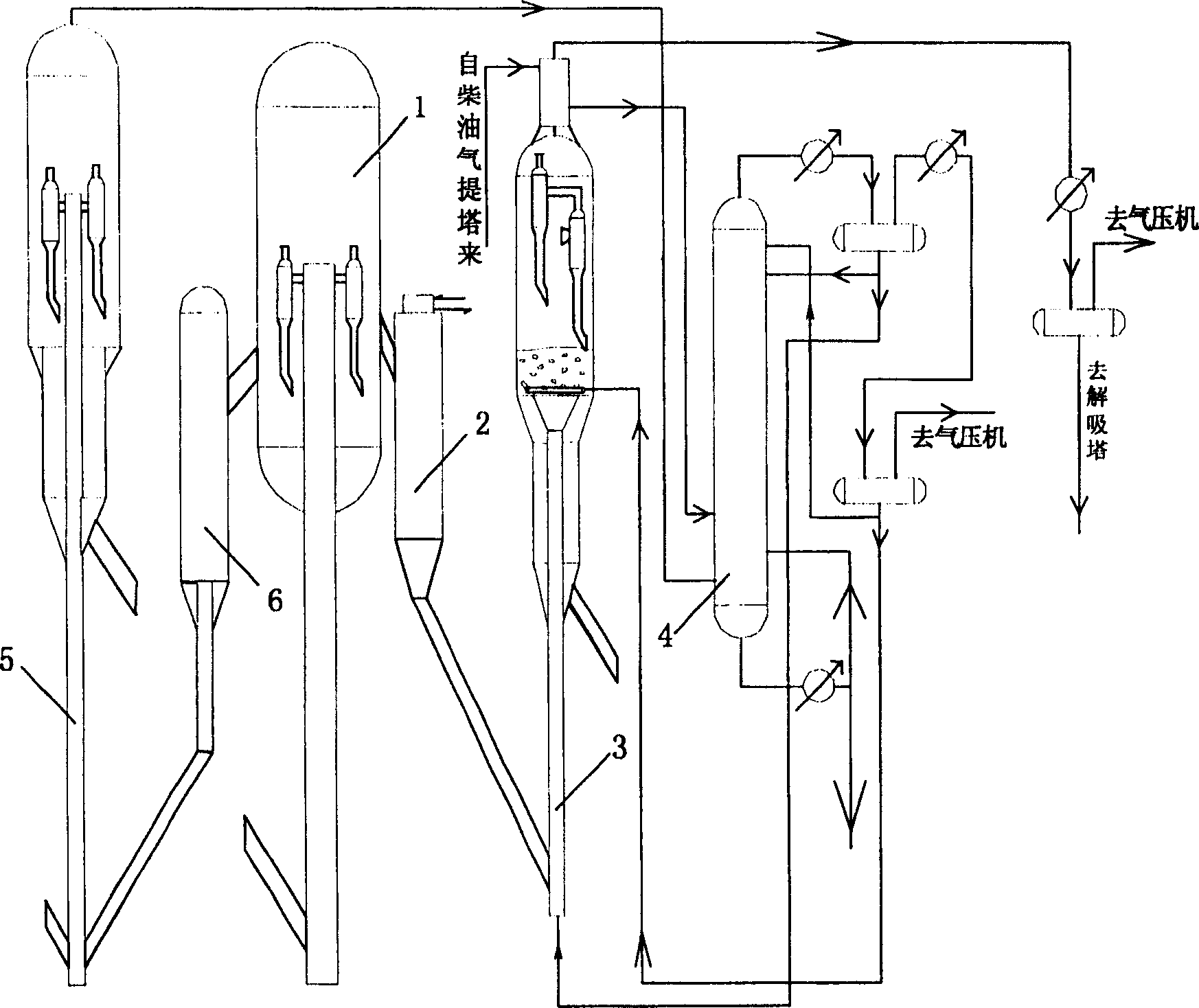

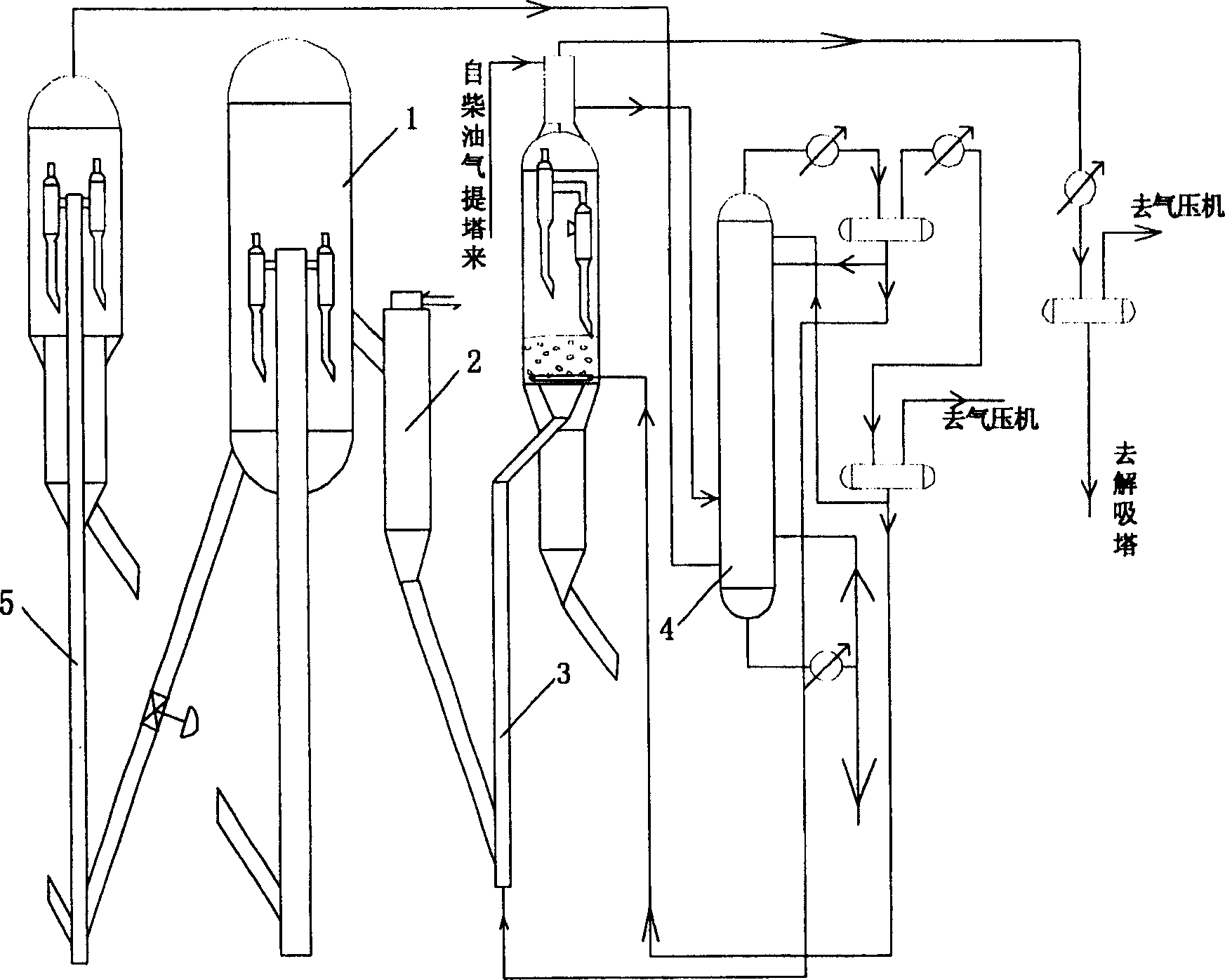

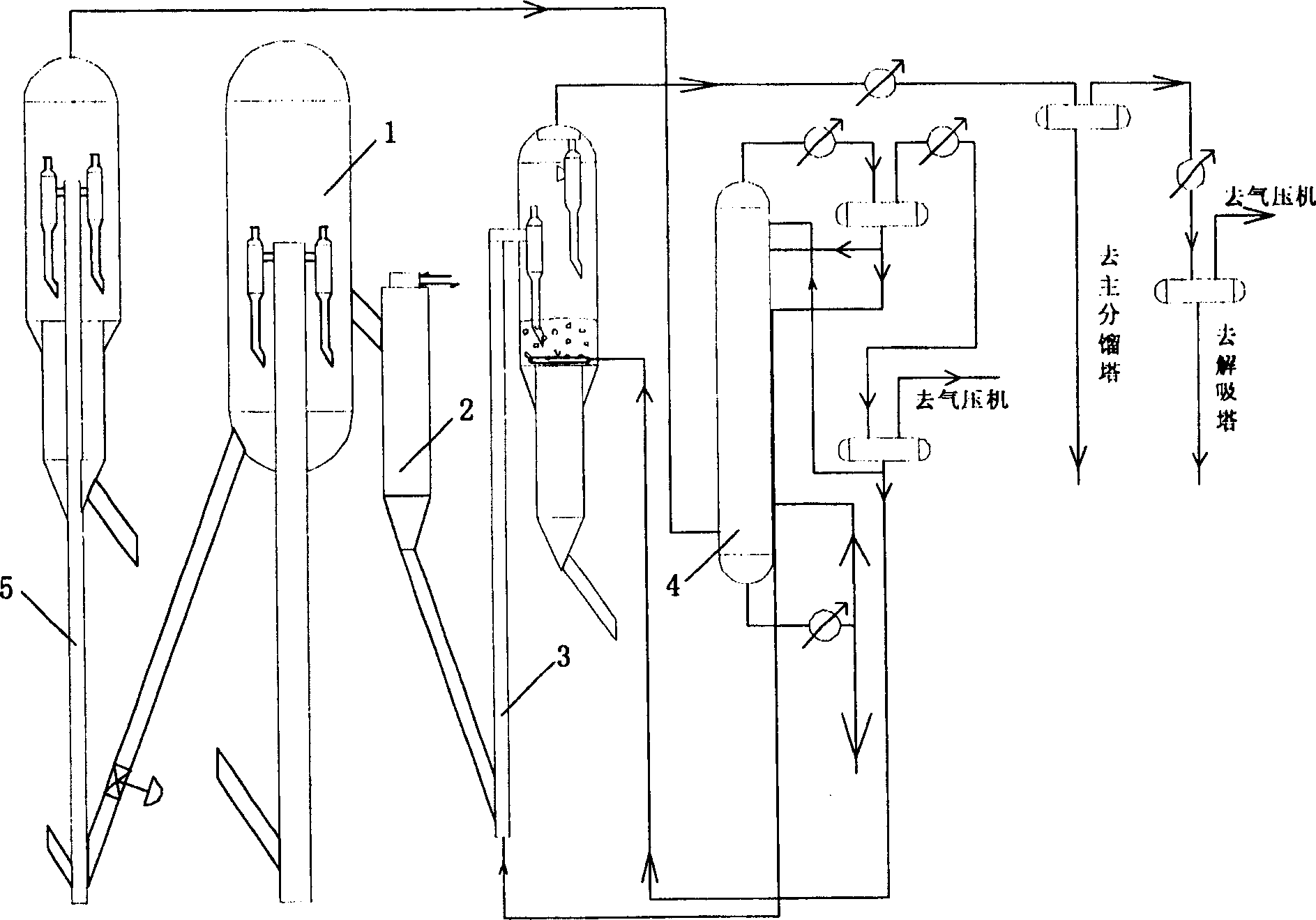

Image

Examples

Embodiment 1

[0041] This embodiment illustrates that the method provided by the present invention can obtain a good gasoline upgrading effect, and the gasoline yield is relatively high.

[0042] The feed oil and catalyst entering the cracking reactor are the same as those in Comparative Example 1. The outlet temperature of the riser reactor is 500°C, the lower temperature of the gasoline upgrading riser reaction section is 580°C, and the upper temperature is 490°C, dense phase fluidized bed The bed temperature is 420°C, other operating conditions are listed in Table 3, the product distribution is listed in Table 4, Table 5 lists the properties of gasoline, and the gasoline composition analysis is listed in Table 6.

[0043] Compared with the comparative example, when the raw materials are the same, Example 1 adopts the combined process of the present invention to increase the conversion rate of heavy oil raw materials by 2.30% (to the raw materials), and increase the liquefied gas yield by 2.2...

Embodiment 2

[0045] This embodiment illustrates that the method provided by the present invention can obtain a good gasoline upgrading effect, and the gasoline yield is relatively high.

[0046] The feed oil entering the cracking reactor is the same as that of Comparative Example 1. The outlet temperature of the riser reactor is 505°C, the lower temperature of the gasoline upgrading riser reaction section is 540°C, and the upper temperature is 450°C. The dense fluidized bed layer The temperature is 380°C, other operating conditions are listed in Table 3, the product distribution is listed in Table 4, Table 5 lists the properties of gasoline, and the gasoline composition analysis is listed in Table 6. The catalyst B used in Example 2 is slightly different from the catalyst used in the comparative example, and basically belongs to the same type of catalyst.

[0047]Compared with the comparative example, when the raw materials are the same, Example 2 adopts the combined process of the present inv...

Embodiment 3

[0049] This embodiment illustrates that the method provided by the present invention can obtain a good gasoline upgrading effect, and the gasoline yield is relatively high.

[0050] The feed oil and catalyst entering the cracking reactor are the same as those in Comparative Example 1. The outlet temperature of the riser reactor is 500°C, the lower temperature of the gasoline upgrading riser reaction section is 510°C, and the upper temperature is 420°C, dense phase fluidized bed The bed temperature is 350°C, other operating conditions are listed in Table 3, the product distribution is also listed in Table 4, Table 5 lists the properties of gasoline, and the gasoline composition analysis is listed in Table 6.

[0051] Compared with the comparative example, when the raw materials are the same, Example 3 adopts the combined process of the present invention to increase the conversion rate of heavy oil raw materials by 2.38% (to the raw materials), and increase the liquefied gas yield b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com