Device for transferring electronic components from inclined supply track to another element

A technology of electronic components and rails, applied in the directions of electrical components, electrical components, load hanging components, etc., can solve the problems of easy damage, complicated pick-and-place devices, damage to related components, etc., to eliminate the danger of damaged components and avoid system blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

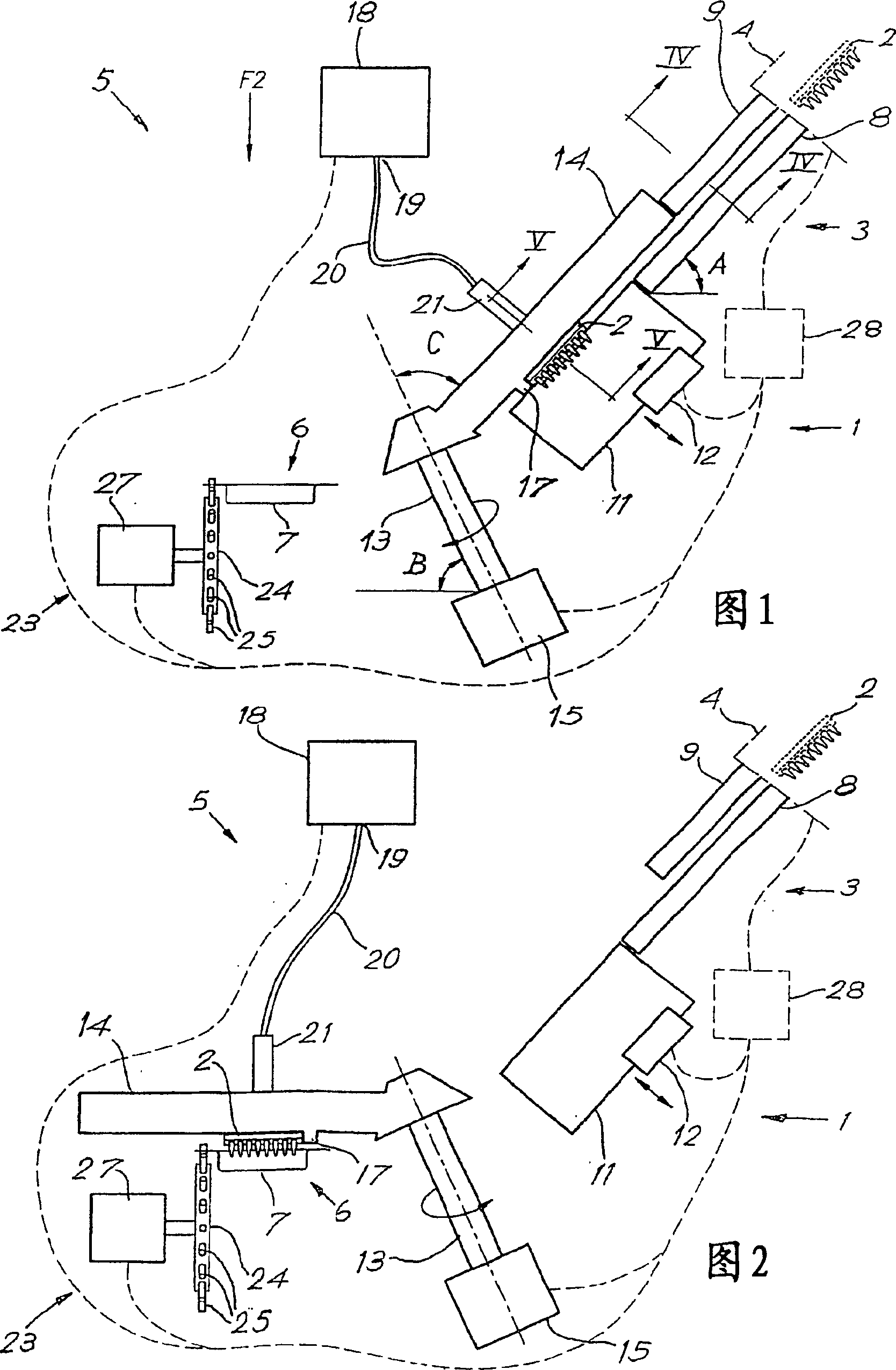

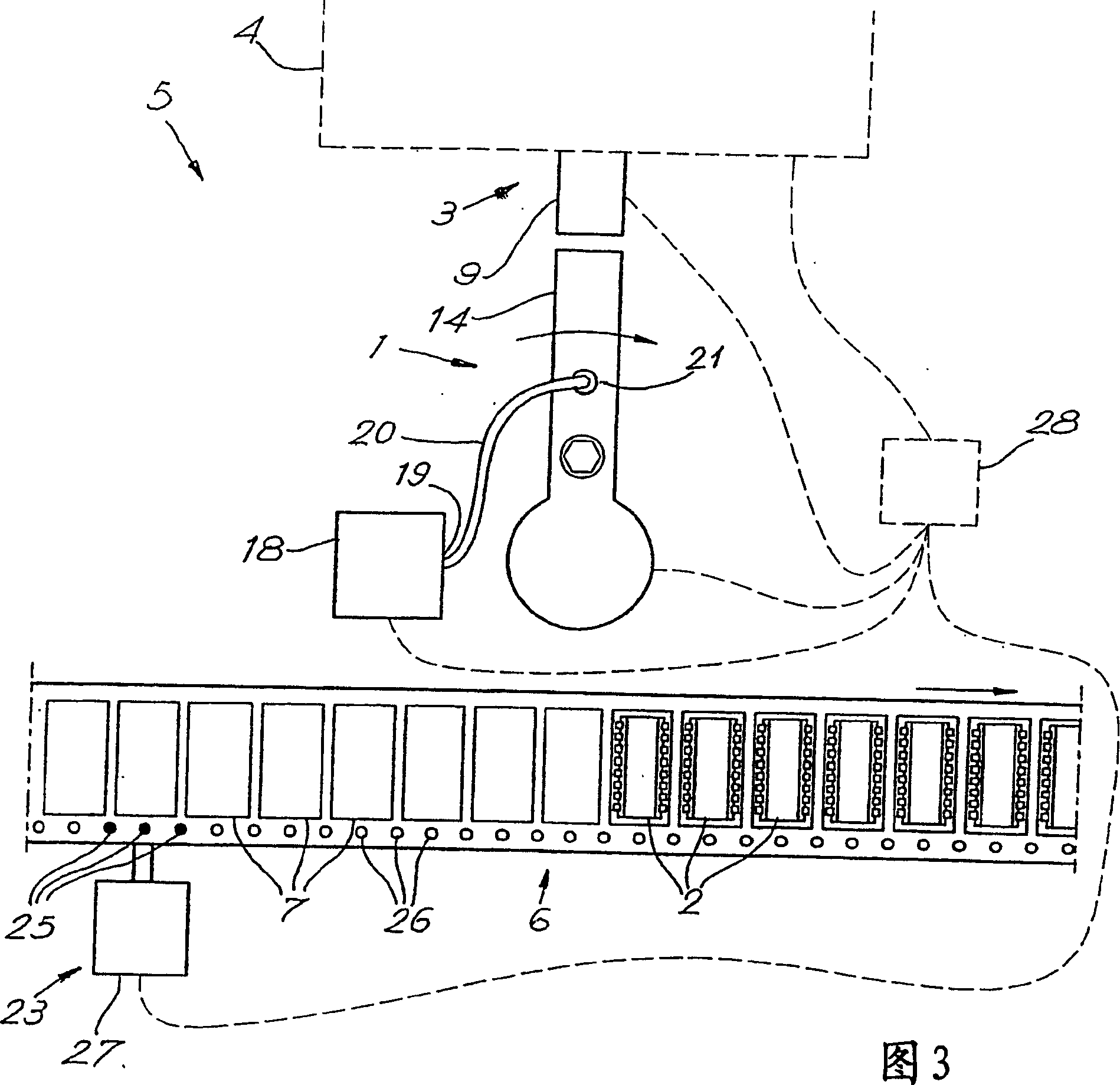

[0023] Figures 1 to 5 show a device 1 according to the invention for transferring electronic components 2 from an inclined gravity supply track 3 to a receiving unit 6, wherein the supply track 3 receives individual electronic components from a packaging machine 5 inspection supply room 4. Components 2 , here the receiving unit is a packaging strip in horizontal position comprising a series of pockets 7 equally spaced along the longitudinal direction of the strip and accommodating individual components 2 .

[0024] The gravity supply track 3 extends along a vertical plane and faces the exit of the electronic components 2 released from the above-mentioned test supply compartment 4 .

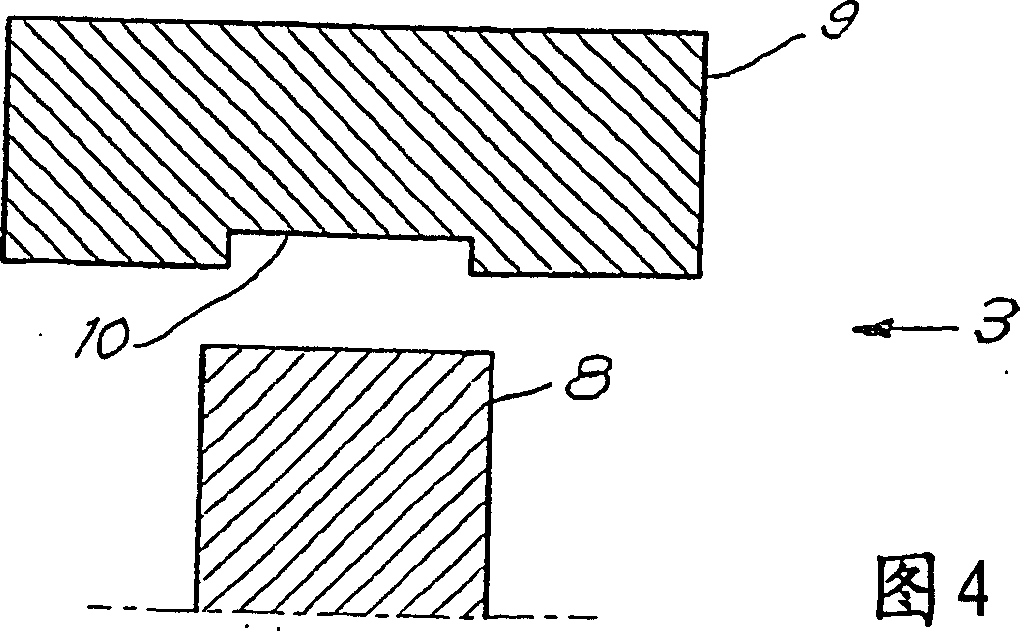

[0025] Said gravity supply rail 3 comprises two parallel fixed guide surfaces, respectively 8 and 9, separated by a small distance, one above the other, inclined at an inclination A, which in the example shown The inclination angle is an angle of 45°, but can also be of different values.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com