Bilayer inlet gas spray nozzle in use for metal-organic chemical vapor deposition device

A metal-organic chemistry and vapor deposition technology, which is applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of not easy to mix fully and uniformly, long distance between tubes, etc. Reduces pre-reaction and facilitates cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

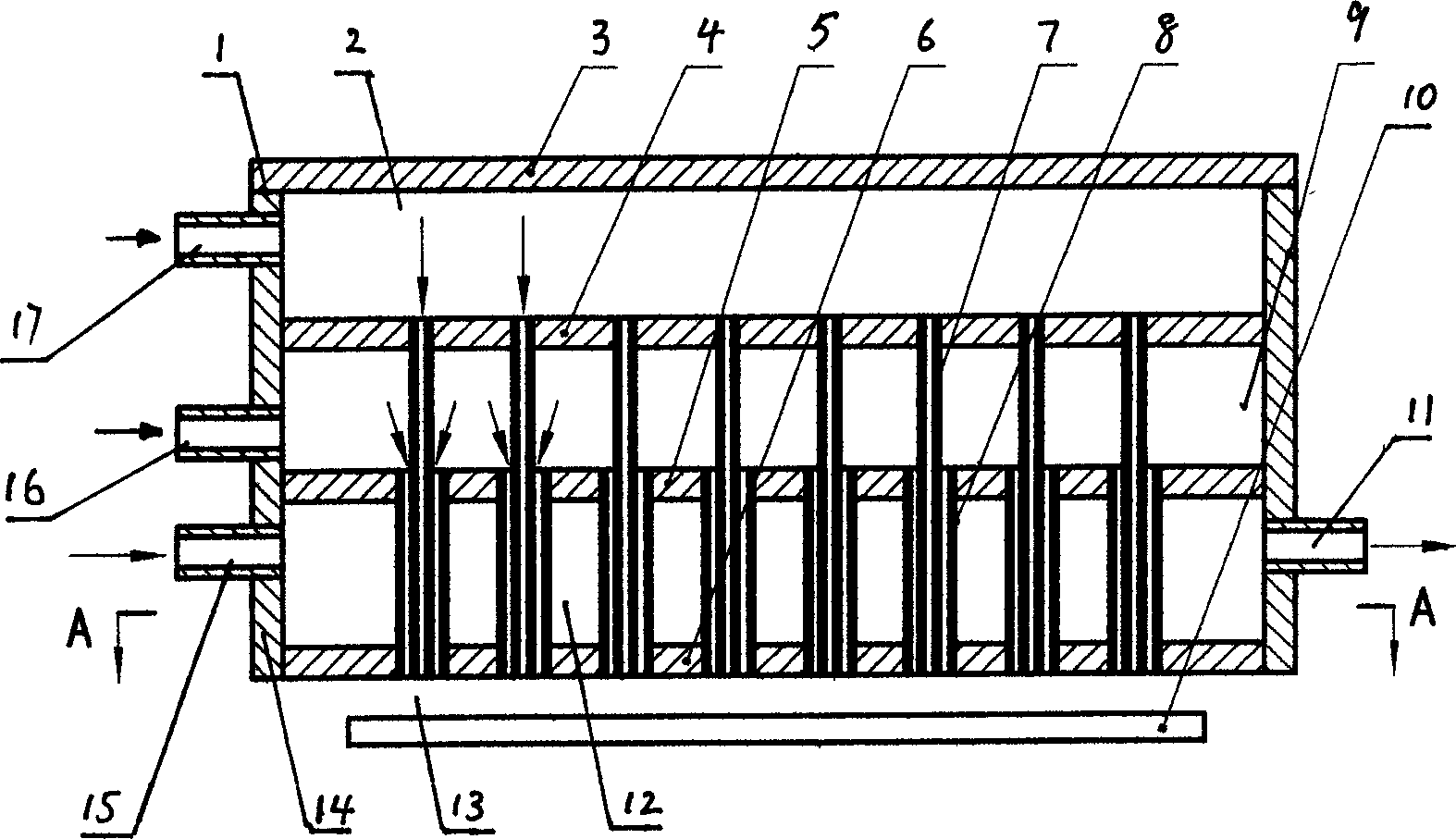

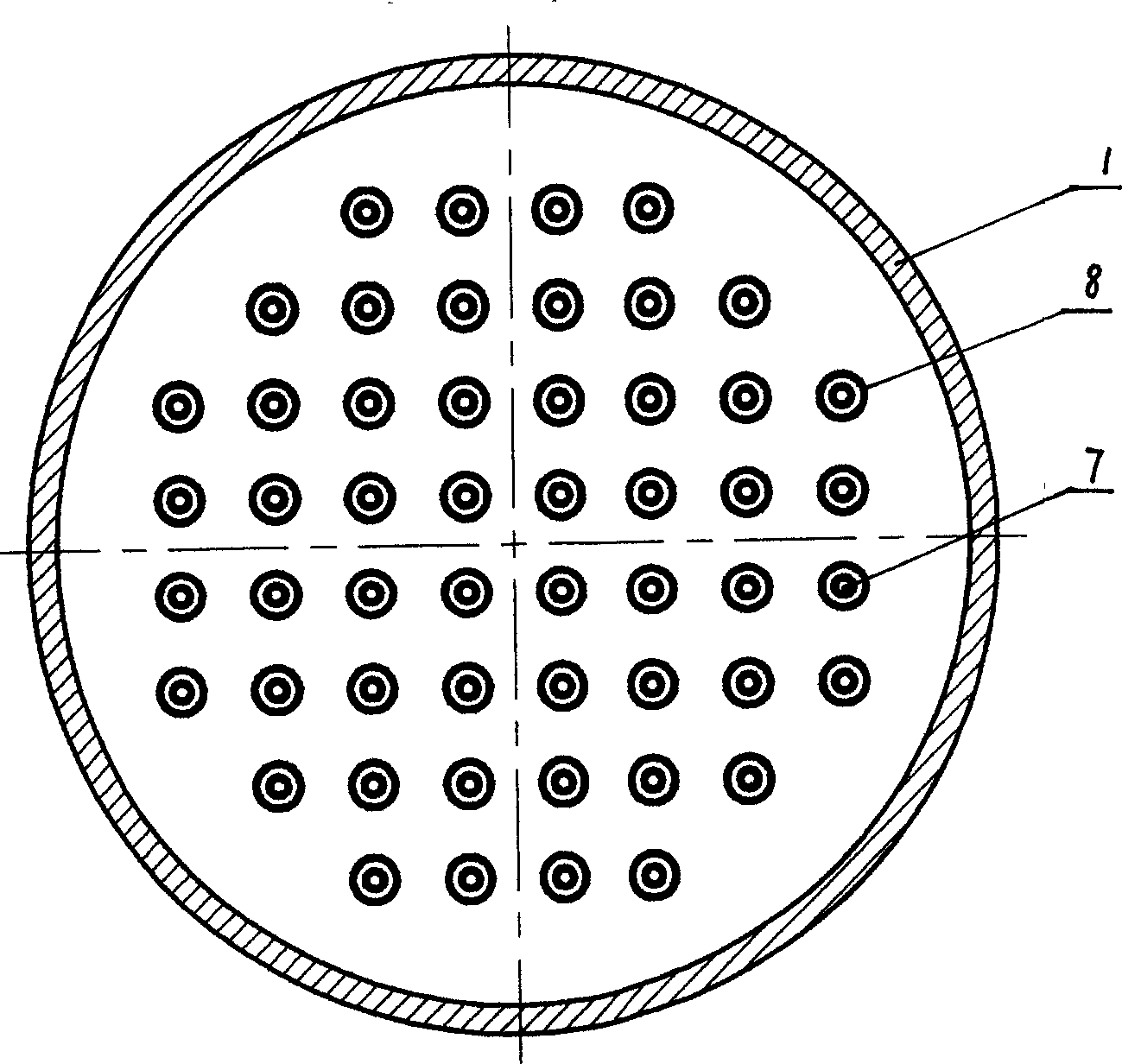

[0010] The present invention comprises a closed outer shell 1, in which an upper middle plate 4 and a lower middle plate 5 are fixed, a sealed upper air intake cavity 2 is formed between the top plate 3 and the upper middle plate 4, and the upper middle plate 4 forms a sealed lower air intake chamber 9 with the lower middle plate 5, and an upper air intake pipe 17 communicating with the upper air intake chamber 2 and a lower air inlet pipe 17 communicating with the lower air intake chamber 9 are installed on the side wall 14 of the outer casing 1. Trachea 16, the upper air outlet pipe 7 communicating with upper air inlet chamber 2 and reaction chamber 13 is installed between the upper middle layer plate 4 and the base plate 6, and the lower air inlet chamber 9 and the lower air inlet chamber 9 are installed between the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com