Triaxial compression mesomechanics test unit for overall process of rock burst in chemical corrosion

A technology of triaxial compression and chemical corrosion, applied in the direction of applying stable tension/pressure to test material strength, test wear resistance, etc., can solve the problems that cannot be realized, and achieve the effect of simple device, reliable test method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

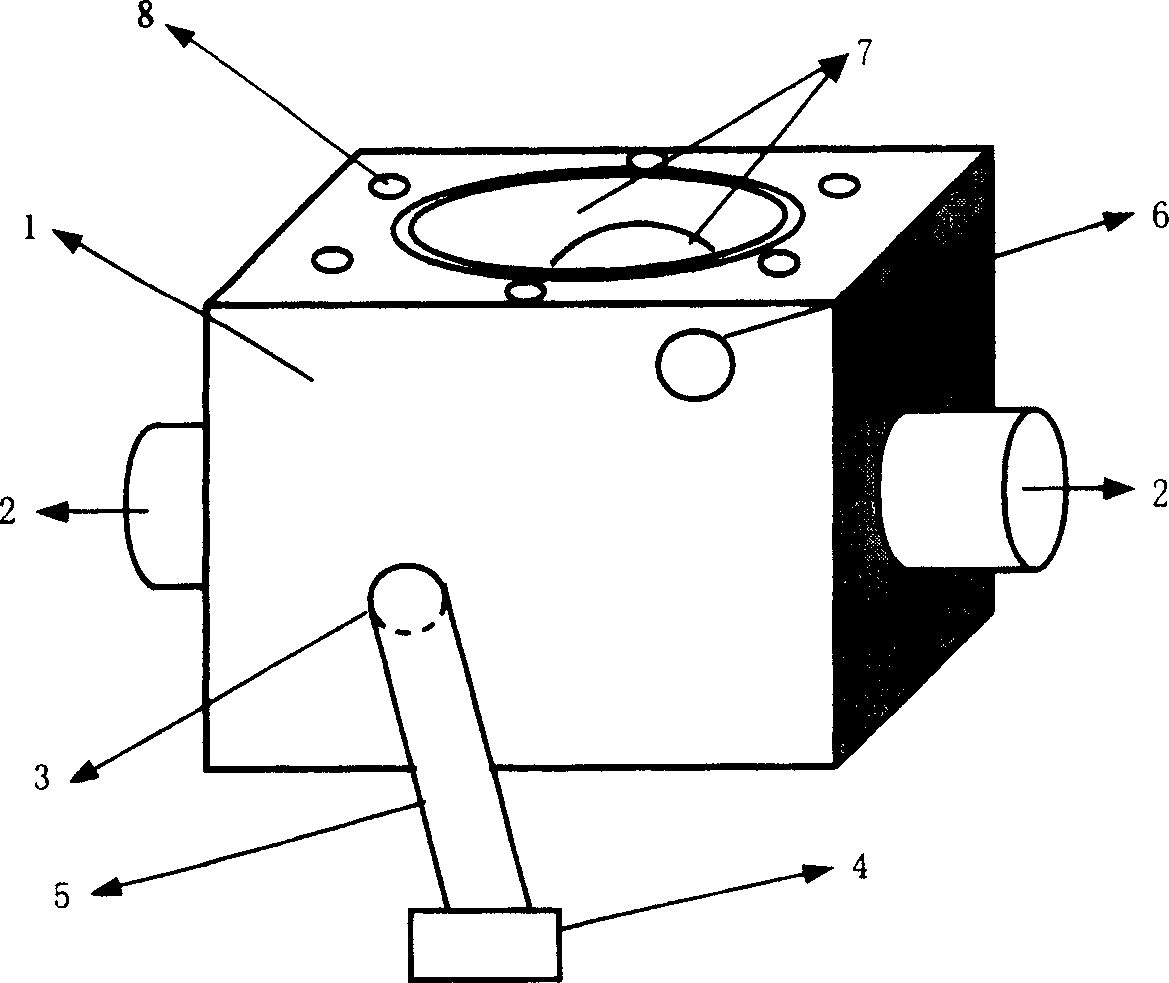

[0024] Depend on figure 1 It can be seen that a triaxial compression mesomechanics test device for the whole process of rock fracture under chemical corrosion of the present invention includes a box body 1, a pair of loading shafts 2, a water nozzle 3, a supercharger 4, a stainless steel pipe 5, and an exhaust valve 6 The box body 1 is a hollow cuboid, the top of the box body 1 and one side thereof are transparent materials 7 such as plexiglass, and other parts are made of stainless steel, wherein the transparent material 7 at the top of the box body 1 is sealed with the box body with an O-ring Align the screw holes in the transparent material 7 with the screw holes 8 on the box body 1, and fix them on the box body 1 with screws. There is a coaxial round hole in the middle of both ends of the box body 1, and a pair of loading shafts 2 are cylinders. body, the size of which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com