Bistable four-way electromagnetic reversing valve

An electromagnetic reversing valve and bistable technology, which is applied to multi-way valves, valve details, valve devices, etc., can solve the problems of complex structure, poor reversing reliability, and low action sensitivity of four-way electromagnetic reversing valves. Achieve the effects of convenient manufacturing and assembly, reduced cost, and high action sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

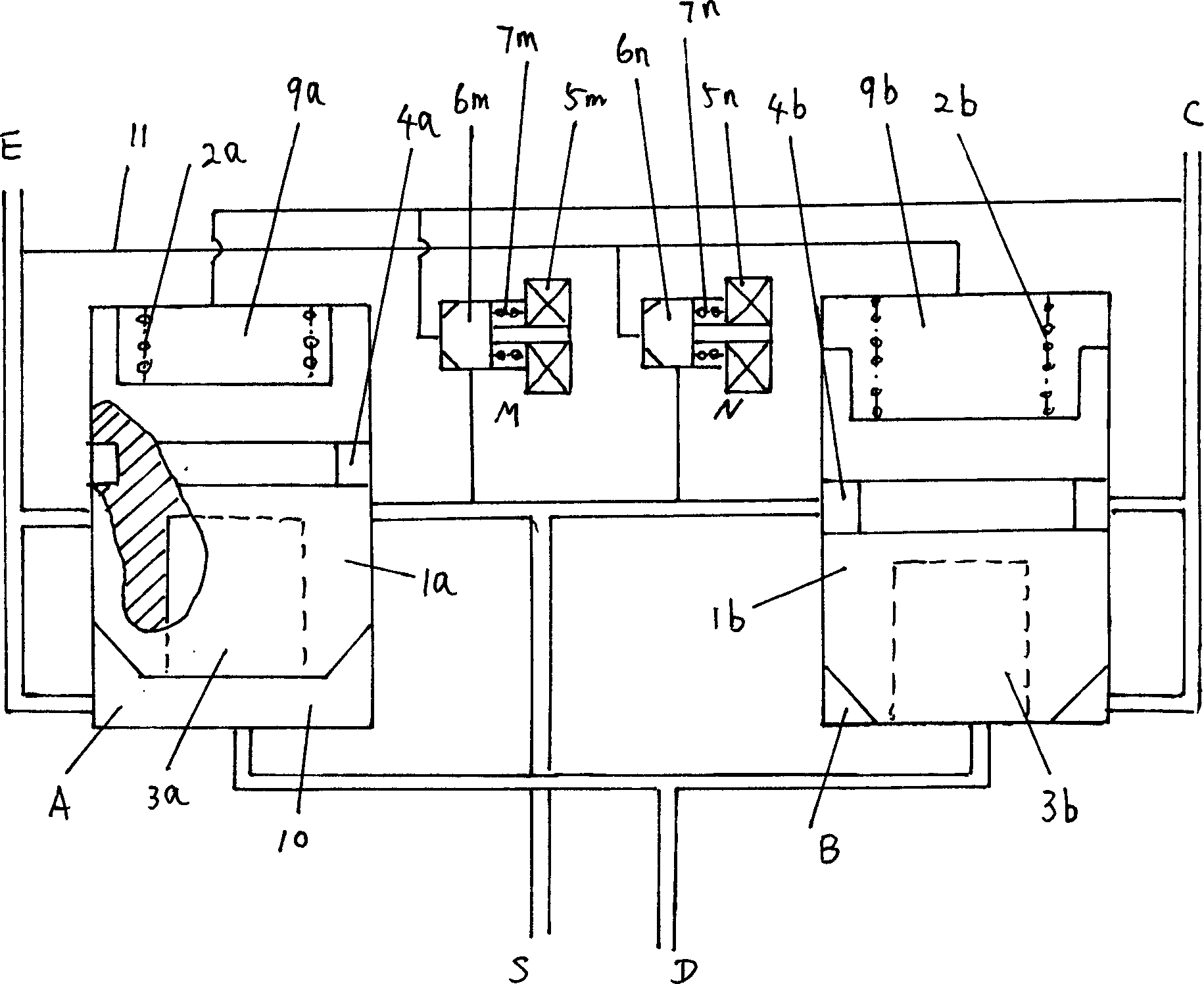

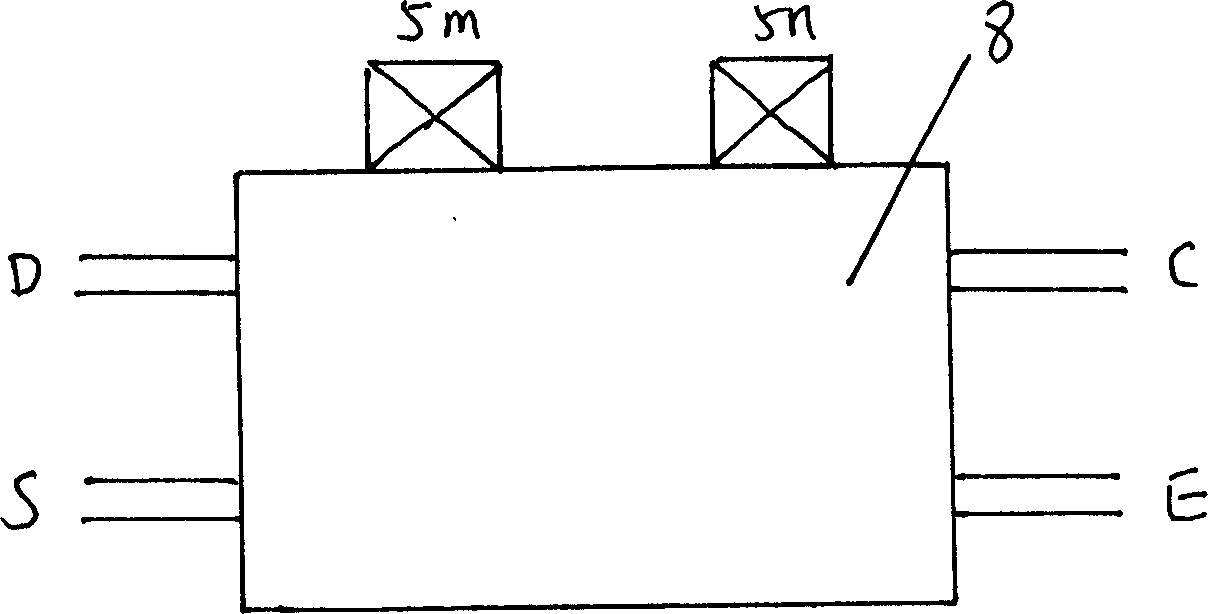

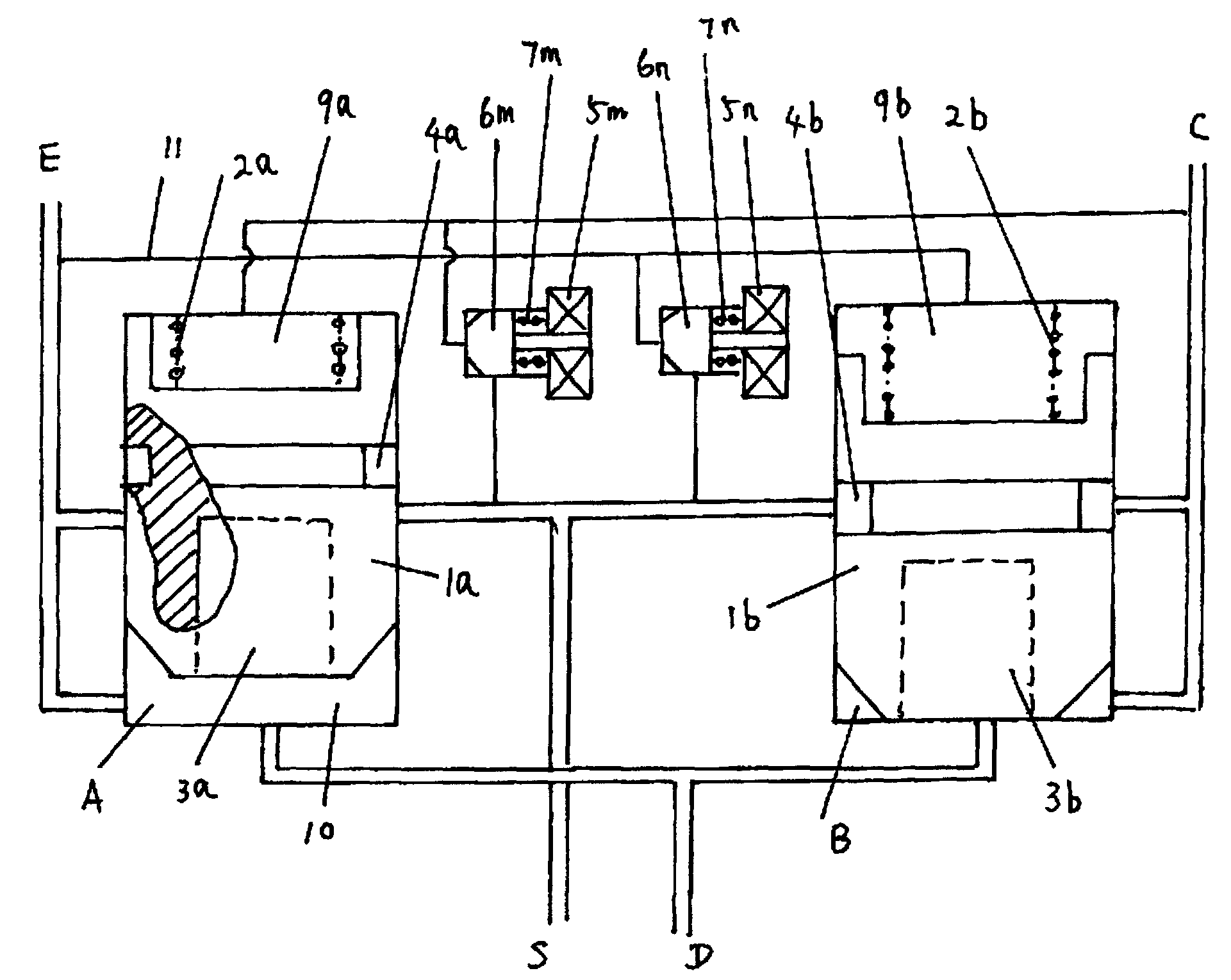

[0011] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention has two valve chambers A and B respectively equipped with spool valve cores 1a and 1b. The front ends of the spool valve cores 1a and 1b are in the shape of a cone, and the distance between their tail ends and the bottom surface of the valve chamber is uniform. Respective springs 2a and 2b are respectively placed. Under normal circumstances, the spools 1a and 1b are respectively at the bottom of the respective valve chambers A and B under the action of the return springs. Cavities 3a, 3b are respectively opened on the front end surfaces of the spool valve cores 1a and 1b, and their arrangement can save material, and they can also make the front ends of the spool valve cores slightly deform to enhance the sealing effect. The spool valve cores 1a and 1b are made of materials such as graphite, rubber, etc., which are resistant to high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com