Electronic equipment cooling member

A technology for cooling components and electronic equipment, which is applied in the construction parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., which can solve the problems of increased product costs and electronic equipment not suitable for use as household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

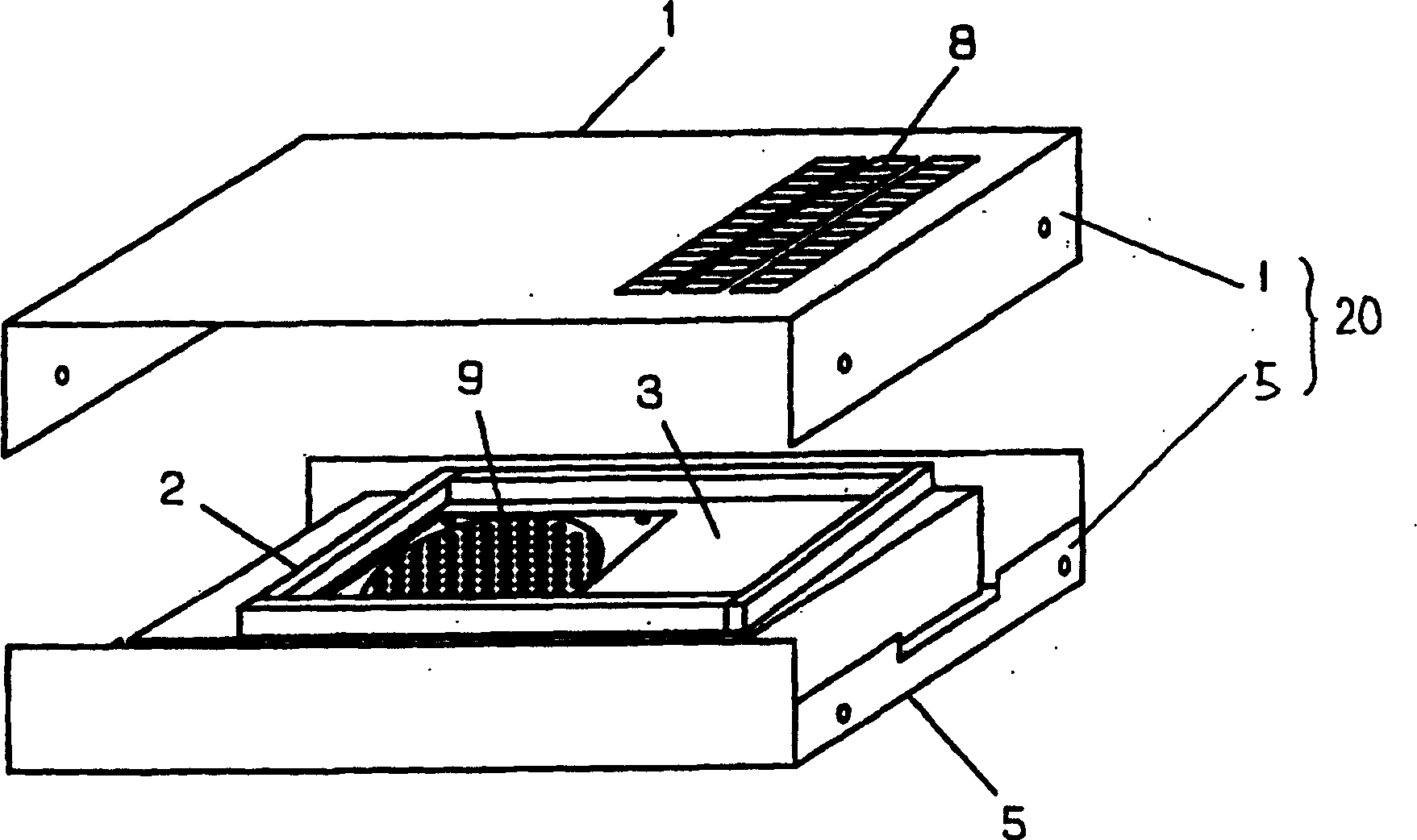

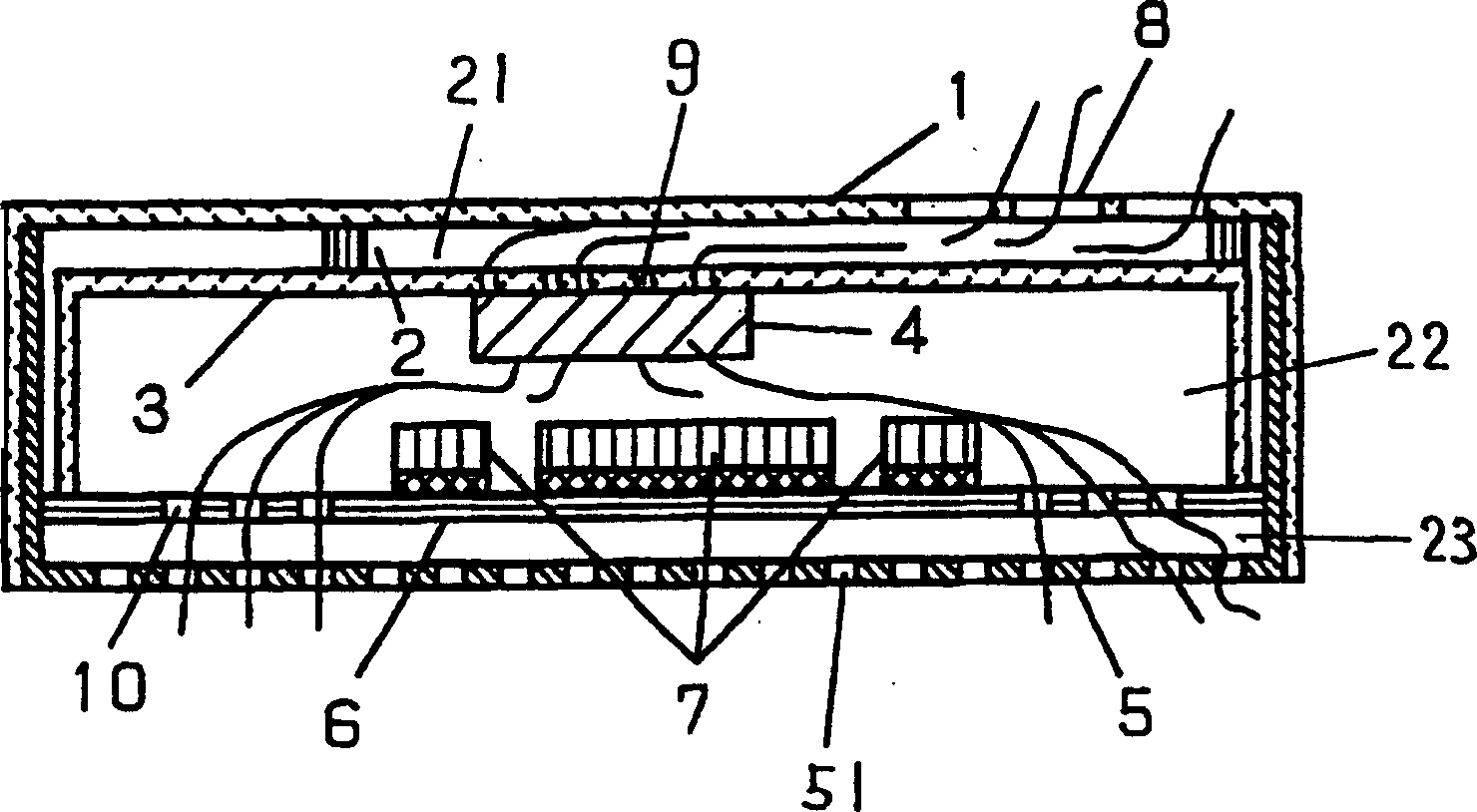

[0035] figure 1 Shown is an exploded perspective view of an electronic equipment cooling member in an exemplary embodiment of the present invention. figure 2 shown from figure 1 A cross-sectional view viewed from the side.

[0036] exist figure 1 and figure 2 Among them, the cooling components of the electronic equipment include: a box structure 20 , a circuit board 6 , a shielding box 3 , a fan 4 and a frame 2 for a wind tunnel. The box structure 20 includes a bottomed container-shaped base 5 and a top plate 1 covering the base 5 . The shielding box 3 covers the circuit substrate 6 and is disposed on the circuit substrate 6 . The fan 4 has the function of discharging the air in the box structure 20 to the outside of the box structure 20 . The circuit board 6 has a heat generating component 7 . The first cooling holes 8 are formed on the top plate 1 . The first ventilation hole 9 is formed on the shielding box 3 . The second vent hole 10 is formed on the circuit sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com