Hollow type back illumination beam component

A backlight, hollow technology, applied to optical components, light guides of lighting systems, light guides, etc., can solve the problems of reduced luminous flux, short light guide paths, affecting the viewing quality of LCD displays of backlight components, etc., to achieve high brightness output, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention discloses a hollow backlight assembly. The hollow backlight assembly can output light evenly in terms of structural design, and obtain higher luminous flux and heat dissipation efficiency. The best embodiment and related implementation modes will be described as follows The content is described in detail.

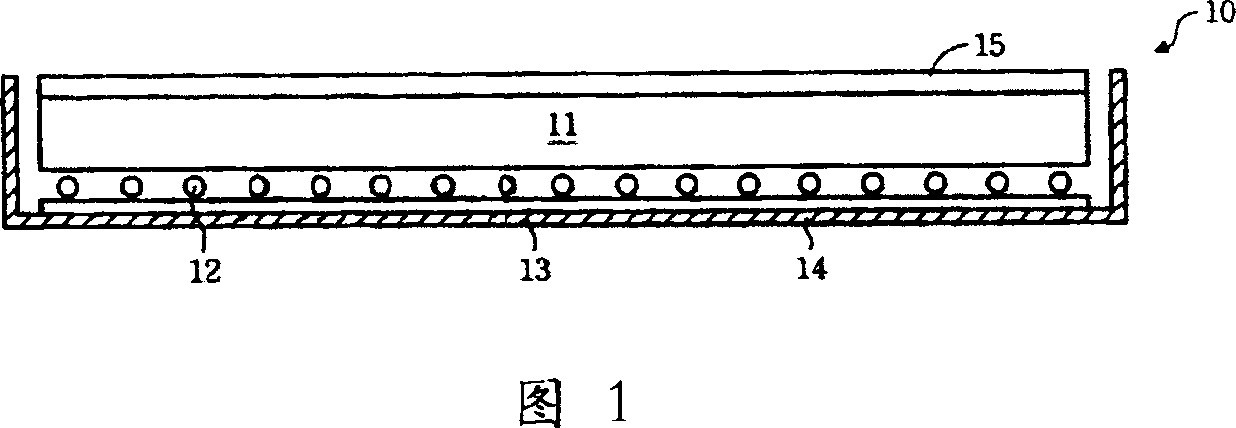

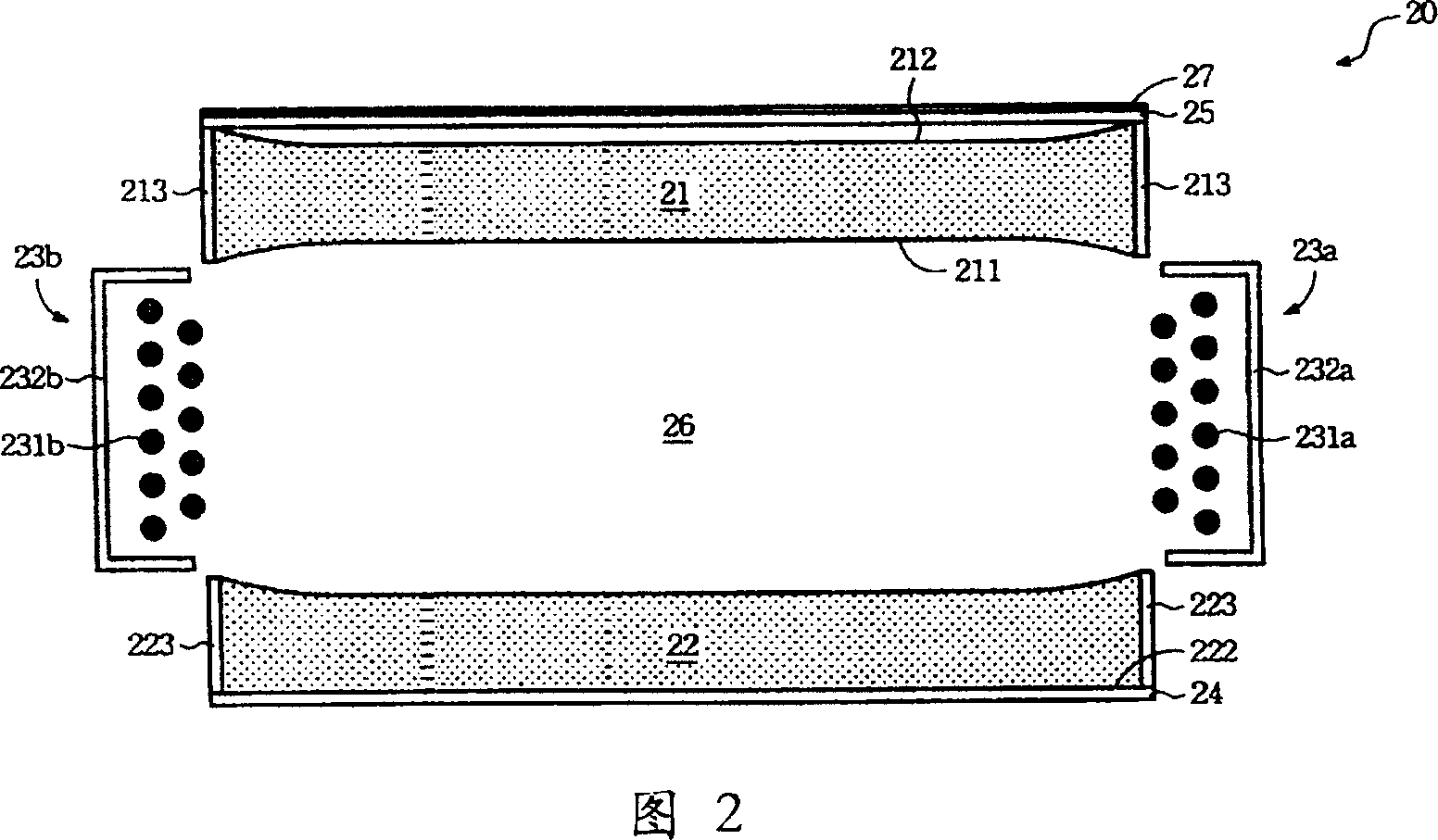

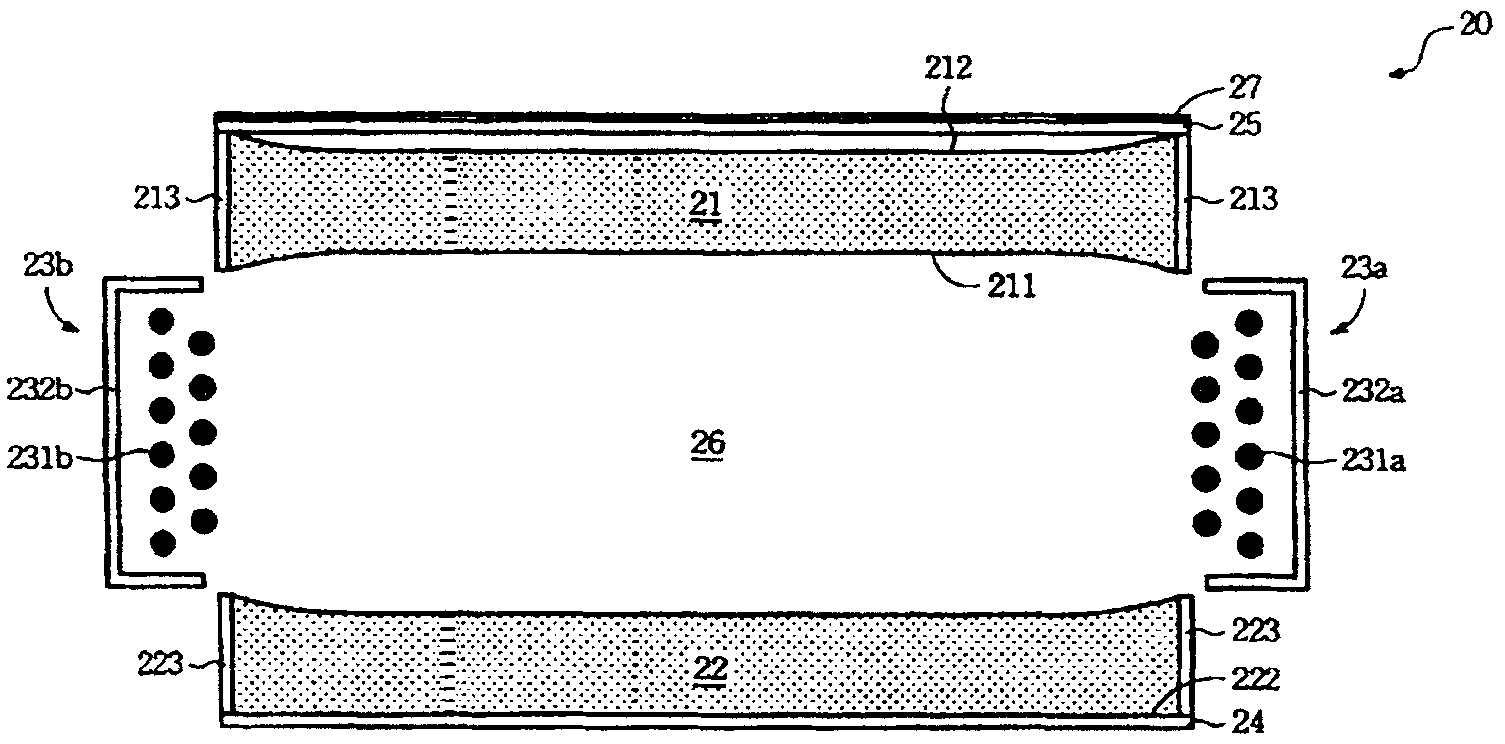

[0029] 2 is a schematic diagram of a hollow backlight assembly 20 of the present invention, the assembly 20 includes a first light guide plate 21 , a second light guide plate 22 , two side light sources 23 , a reflective sheet 24 and a diffuser plate 25 .

[0030] The first light guide plate 21 in the figure is a light-transmitting acrylic resin plate, which includes a first inner surface 211 and a first outer surface 212. The above-mentioned two surfaces are designed as concave curved surfaces, and its purpose is to make the second A light guide plate 21 has a diffusion effect similar to a concave lens. In addition, reflective tapes 213 are pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com