Vertical boiling pot for paper pulp

A cooking pot, vertical technology, applied in the direction of digester, papermaking, textiles and papermaking, etc., can solve the problems of incapable of circulating heating of cooking liquid, incomplete cooking process, uneven heating of steam, etc., to achieve good water drainage and uniform hardness , the effect of large pot capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited thereto.

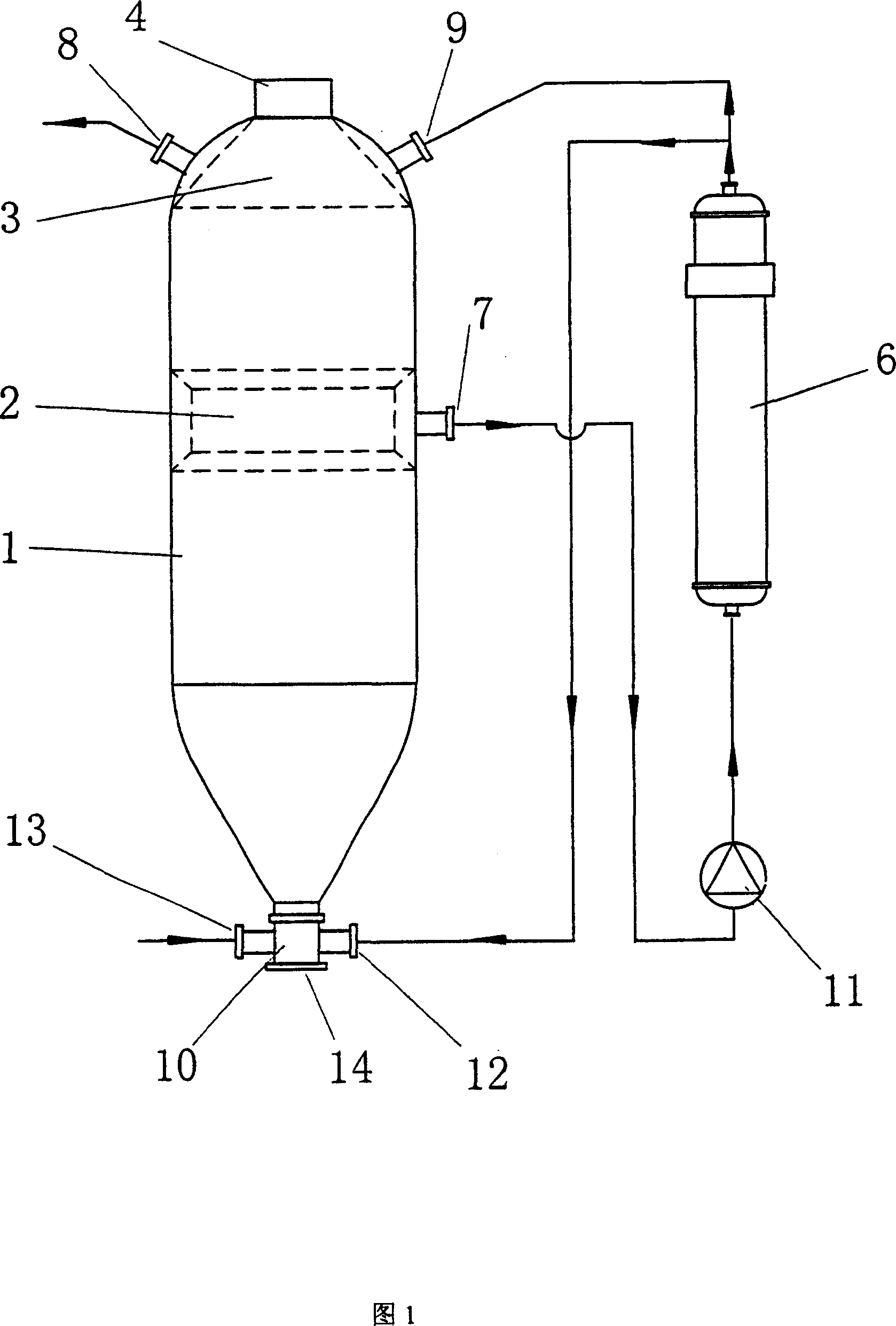

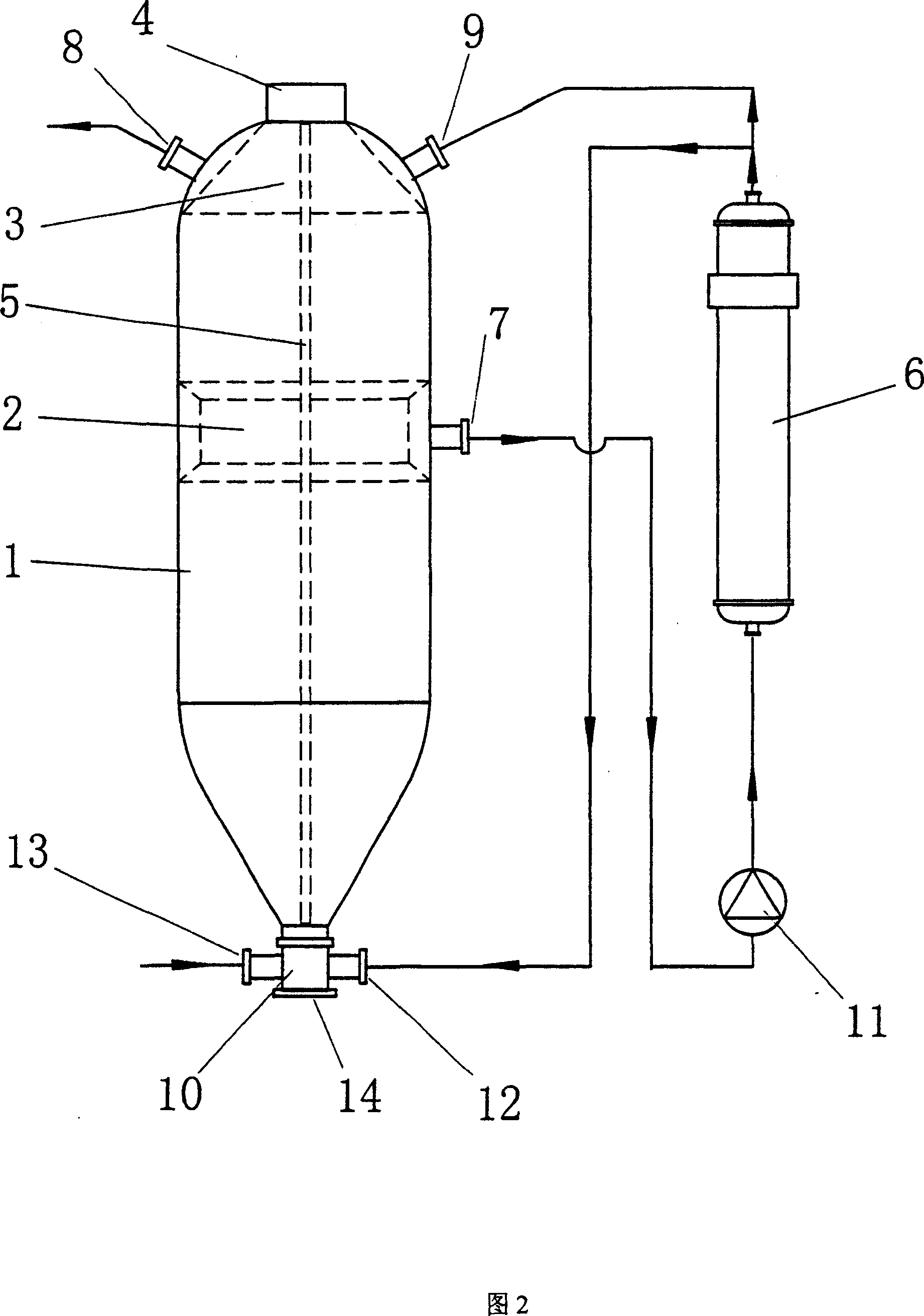

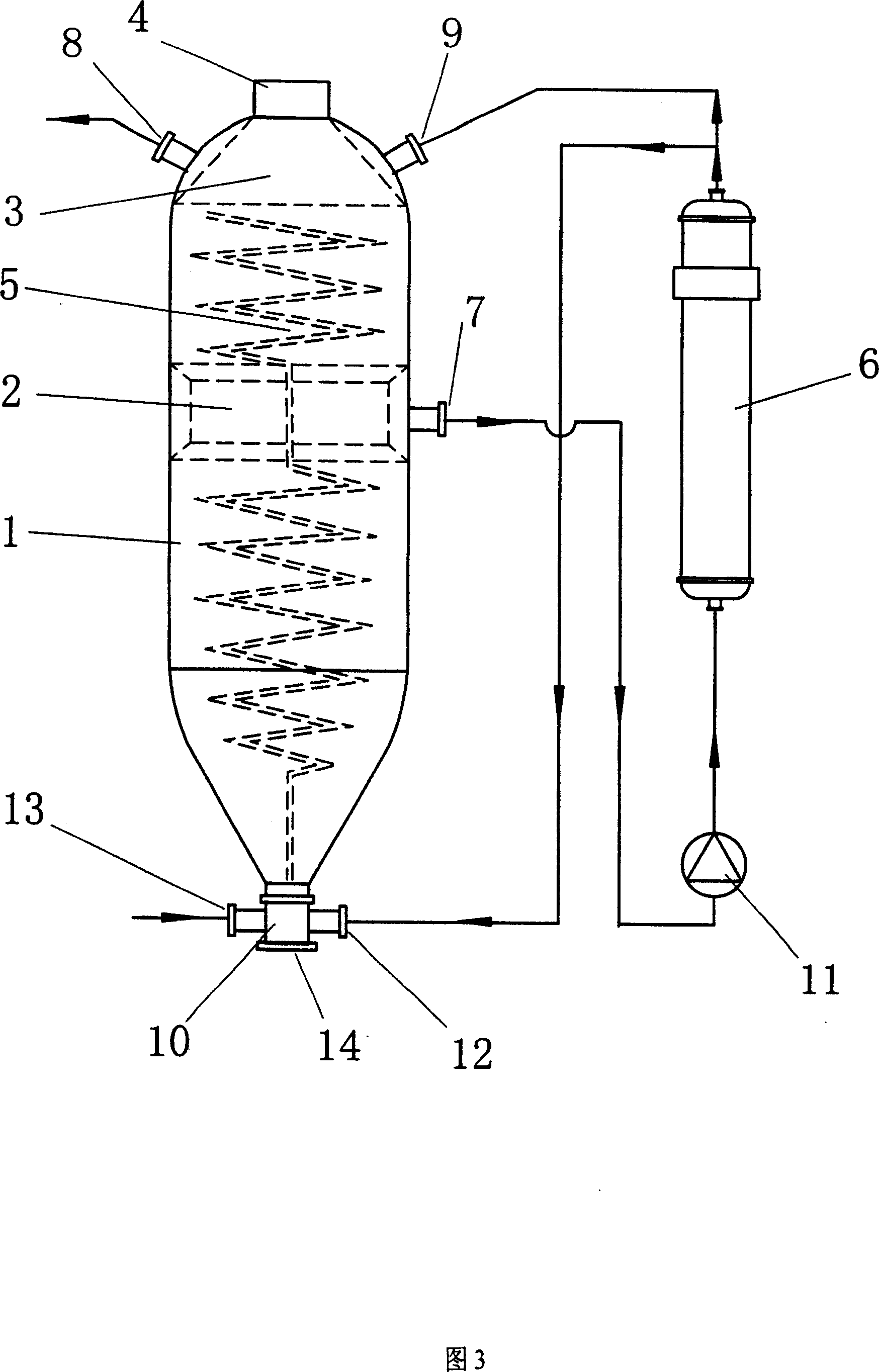

[0023] Shown in Fig. 2, Fig. 3 is the structural representation of novel vertical cooking pot of the present invention. The vertical cooking pot includes: a pot body 1, a heater 6, and a circulation heating pump 11. The pot body is provided with a steam heating pipe 5, which can be one (as shown in the figure), and is a plurality of parallel straight pipes Or spiral coil (as shown in Figure 3) or U-shaped pipe, this steam heating pipe 5 links to each other with the air inlet 10 on the pot body, and this air inlet 10 can be located at the top or the bottom of the pot body, the pot body The upper cone part has an upper filter plate 3 for filtering together, and the middle part of the pot body has a middle filter plate 2 for pumping liquid. There is a suction port 7, and the lower end of the pot body is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com