Single piece of pneumatic gelatious tiny valve

A gel, microvalve technology, applied in microstructure devices without moving elements, microstructure devices composed of elements that move relative to each other, valve operation/release devices, etc. The problem of slow response time and unfavorable manufacturing structure of micro valve actuating components achieves the effects of simple structure, low energy consumption for opening, and strong continuous actuation capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

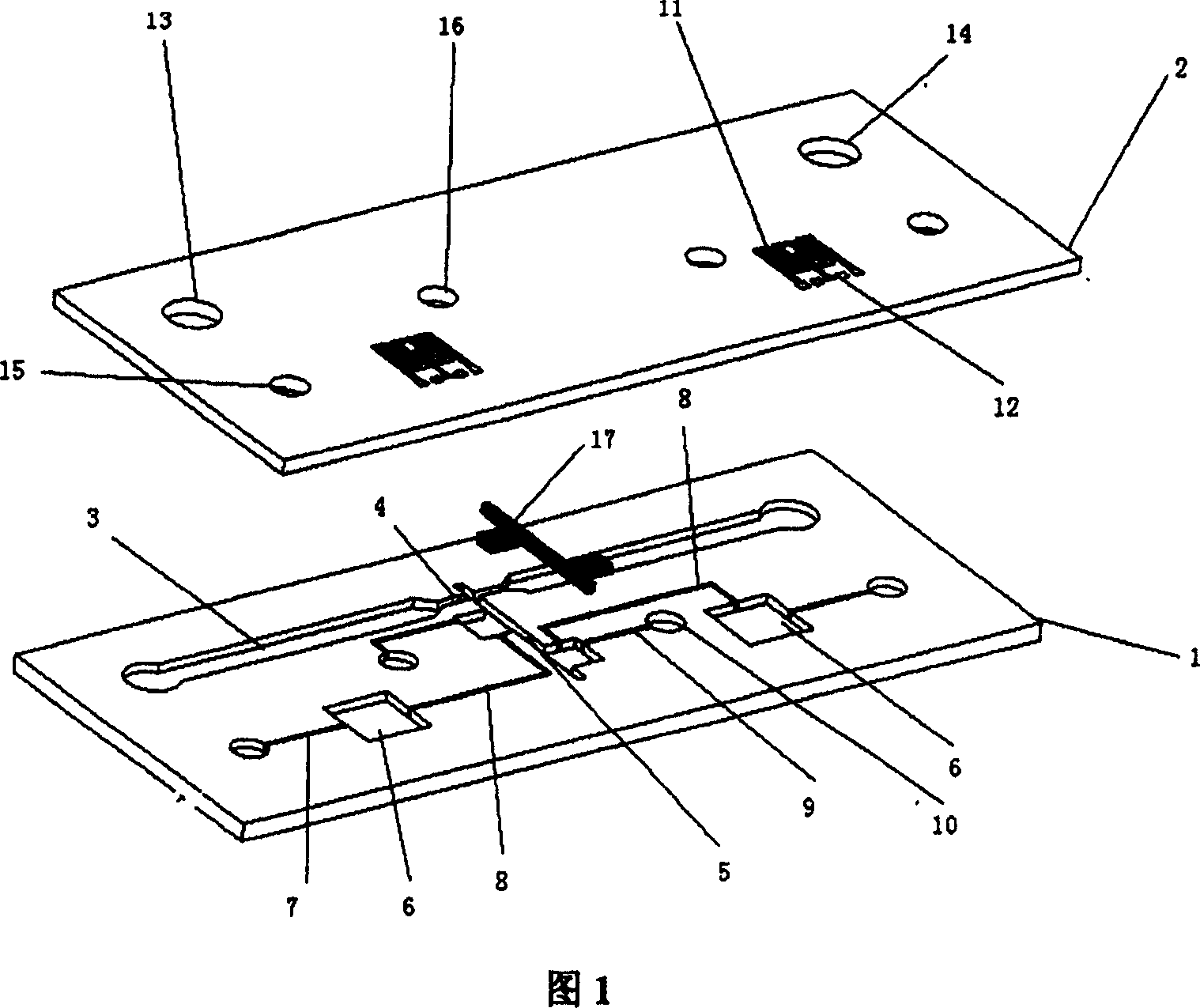

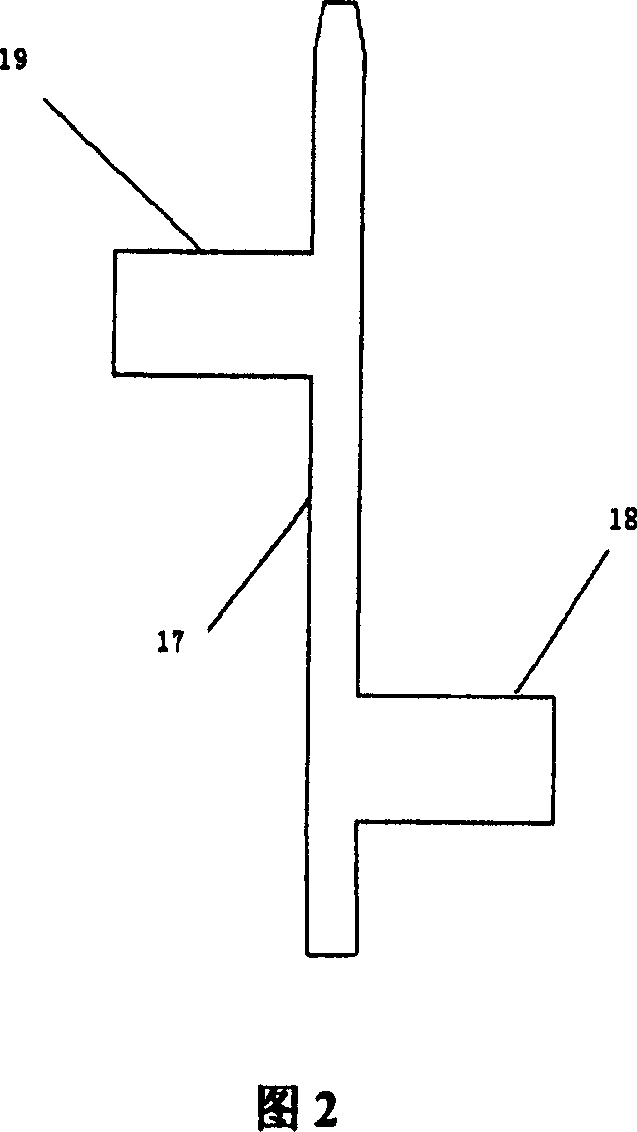

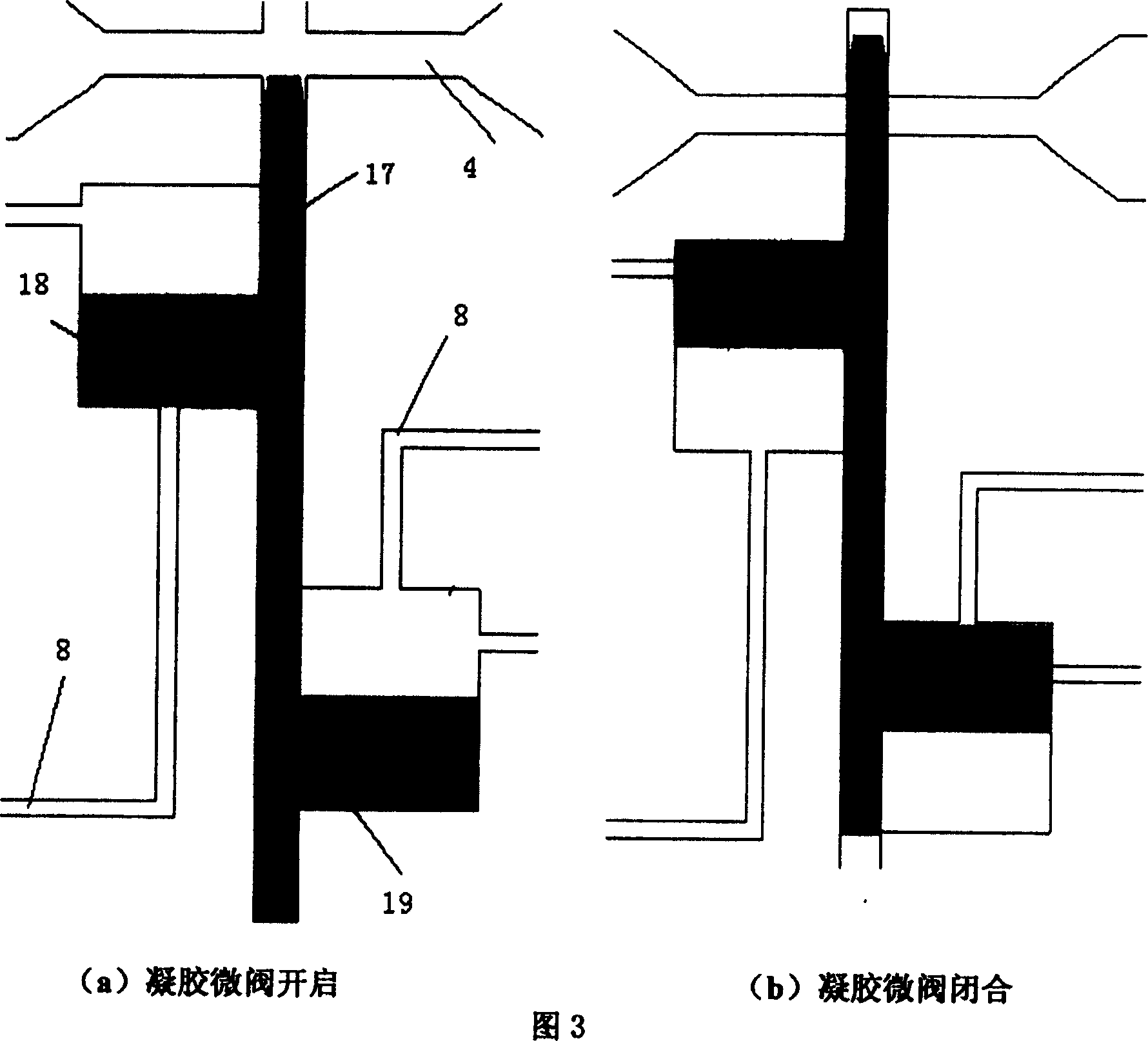

[0020] As shown in FIG. 1 , the present invention consists of a silicone rubber substrate 1 and a glass substrate 2 , and the glass substrate 2 is arranged above the silicone rubber substrate 1 . The silicone rubber substrate 1 includes a main channel 3, a flow-limiting channel 4, a gel microvalve slideway 5, a micro-oxygen pump actuation cavity 6, a micro-oxygen pump sampling channel 7, a micro-oxygen pump actuation airway 8, an auxiliary Channel 9, auxiliary air outlet 10, gel microvalve spool 17, the main channel 3 and the gel microvalve slideway 5 are perpendicular to each other on the silicone rubber substrate 1, and the end of the main channel 3 is connected with one end of the flow-limiting channel 4, And the flow-limiting channel 4 is located in the center of the main channel 3 in the width direction, and is perpendicular to the gel microvalve slideway 5, the gel microvalve spool 17 is in the gel microvalve slideway 5, and the micro oxygen pump actuation chamber There ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com