Micro oxygen pump based on hydrogen peroxide solution decomposition

A technology of hydrogen peroxide and oxygen, which is applied in the direction of oxygen preparation, microstructure devices without moving elements, filtration and separation, etc., can solve the problems of weak driving ability and driving pressure, and achieve strong continuous driving ability, simple structure, and low energy consumption for opening low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

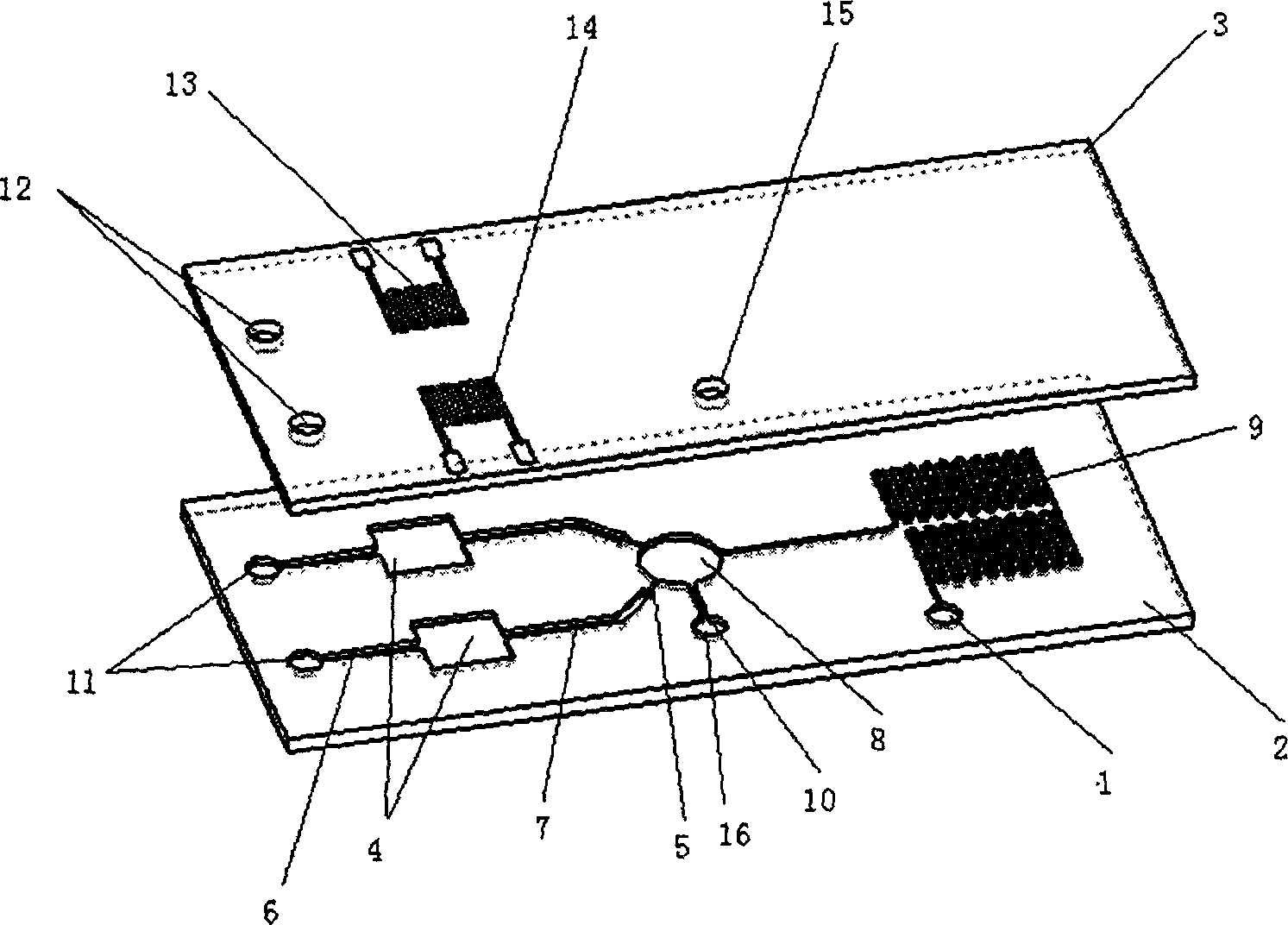

[0018] Such as figure 1 As shown, the present invention is composed of two layers, which are respectively the silicone rubber substrate 2 including the pump cavity structure and microchannels and the glass substrate 3 including the heating electrode and the sensing electrode, and the glass substrate 3 is encapsulated by ultraviolet light irradiation. Arranged above the silicone rubber base 2, the silicone rubber base 2 is provided with parallel hydrogen peroxide pump chambers 4, and hydrogen peroxide inlet microchannels 6 and oxygen outlet microchannels 7 are respectively arranged at opposite positions on both sides of the hydrogen peroxide pump chamber 4, The hydrogen peroxide inlet microchannel 6 is connected to the hydrogen peroxide inlet 11, the end of the oxygen outlet microchannel 7 is connected to the capillary microvalve 5, and the other side of the capillary microvalve 5 is connected to the liquid storage chamber 8, and the lower side of the liquid storage chamber 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com