Rock drill

A technology of rock drilling bits and drilling bits, which is applied in the direction of drill bits, drill pipes, drill pipes, etc., can solve the problems of complex process, rotation-driven key wear, etc., and achieve the reduction of circumferential wear, suppression of torsional bending strength, and improvement of use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

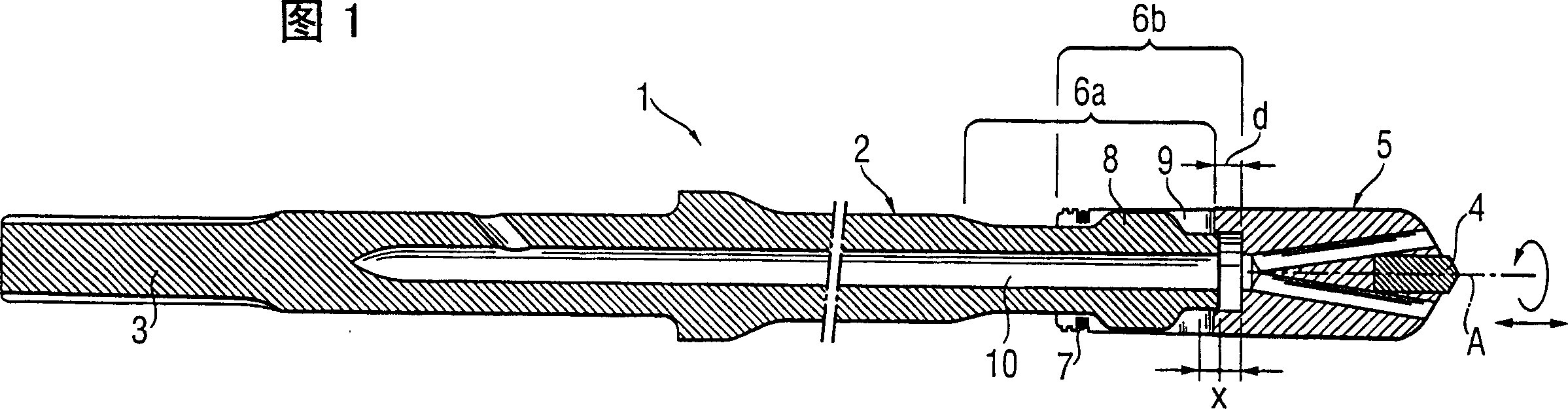

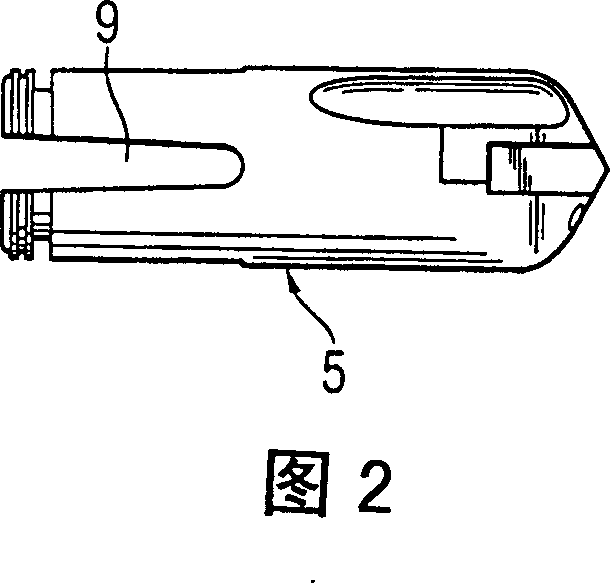

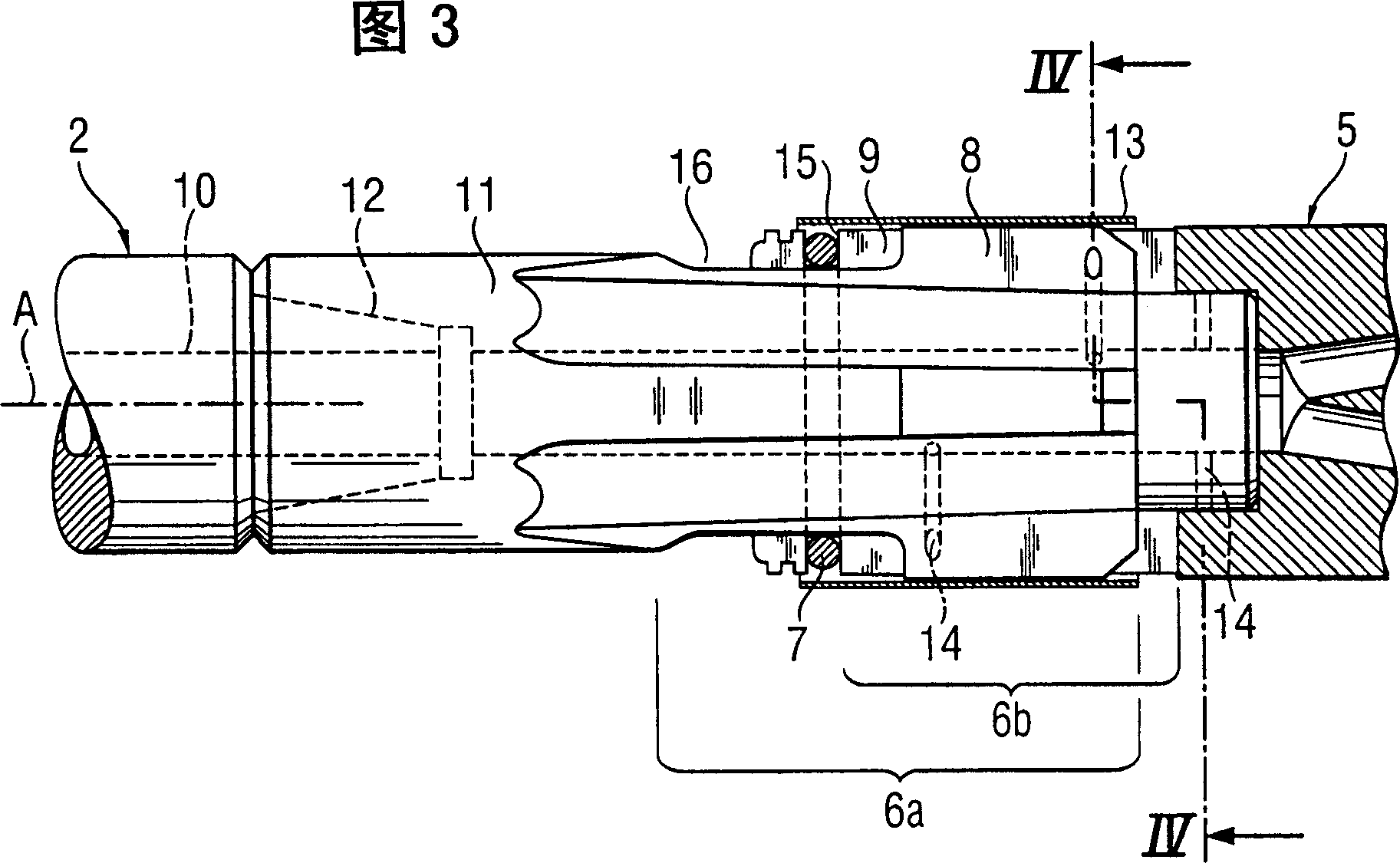

[0026] According to FIG. 1 together with FIG. 2, the drill bit 1 subjected to rotational and impact loads has a drill rod 2 with an insertion end 3 and a drilling head with a hard material tool tip 4 capable of limited axial movement with a length x of 5 mm. 5. The drill rod 2 and the pot-shaped drilling head 5 are connected to each other in a rotationally interlocking manner with a limited axial movement and by means of a locking device 7 via a connection device with a drive-side connection part 6a and an output-side connection part 6b. . On the end of the drill rod 2 that transmits the shock pulses to the bottom of the drill head 5, there are four radially protruding swivel keys 8 that engage the four edges of the swivel face of the pot-shaped drill head 5. Rotating drive grooves 9 distributed in pairs along the diameter of the tool axis A, these grooves end in the direction of the tool tip 4 at a distance d in front of the tank bottom of the drilling head 5, which correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com