Frequency hopping radio station aluminum alloy shell extrusion molding dies

An aluminum alloy shell, extrusion molding technology, applied in the direction of metal extrusion dies, etc., can solve the problems that affect the performance of products, the size cannot be completely consistent, and the cross-sectional shape is complex, so as to achieve simple structure, batch and continuous production. , The effect of high product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

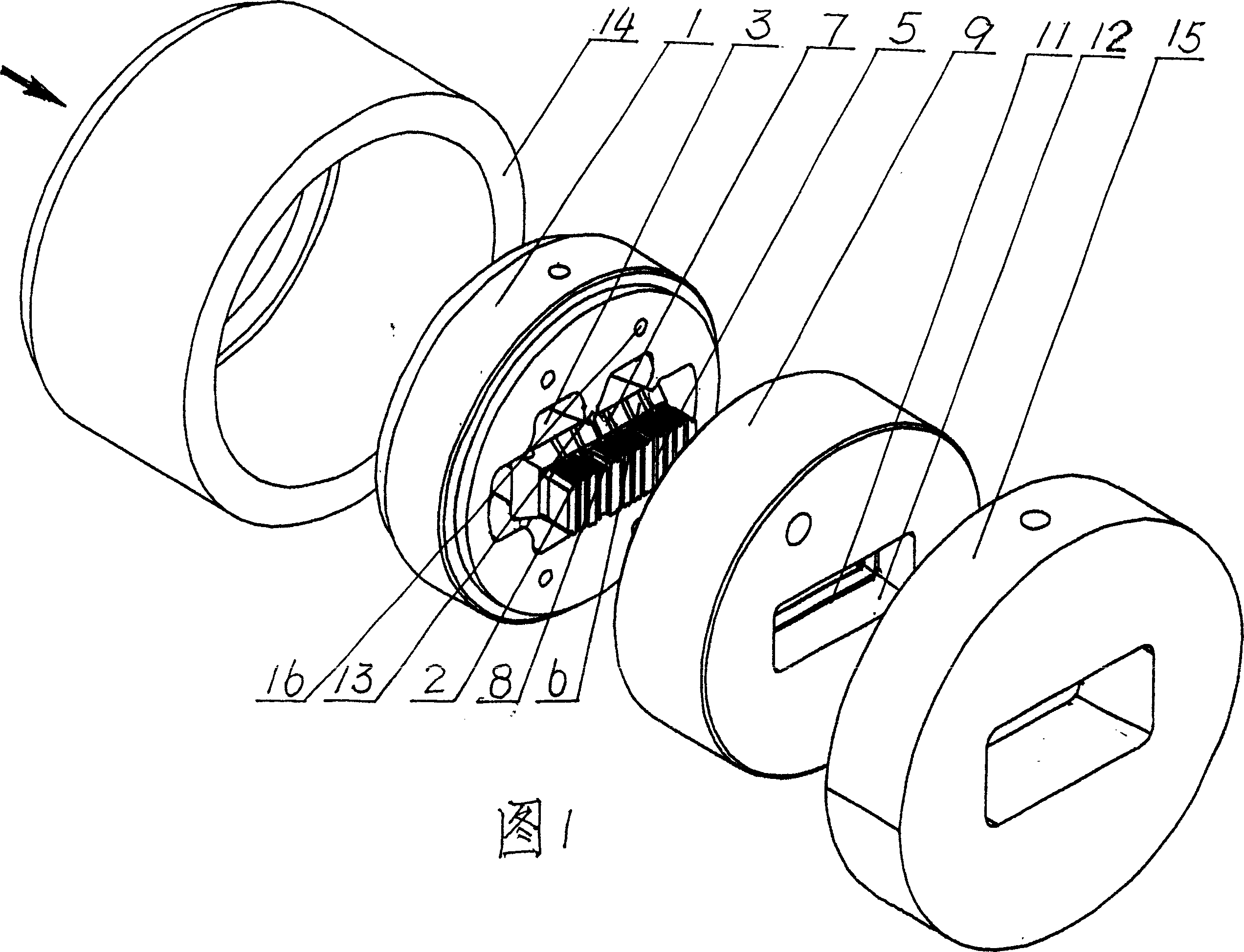

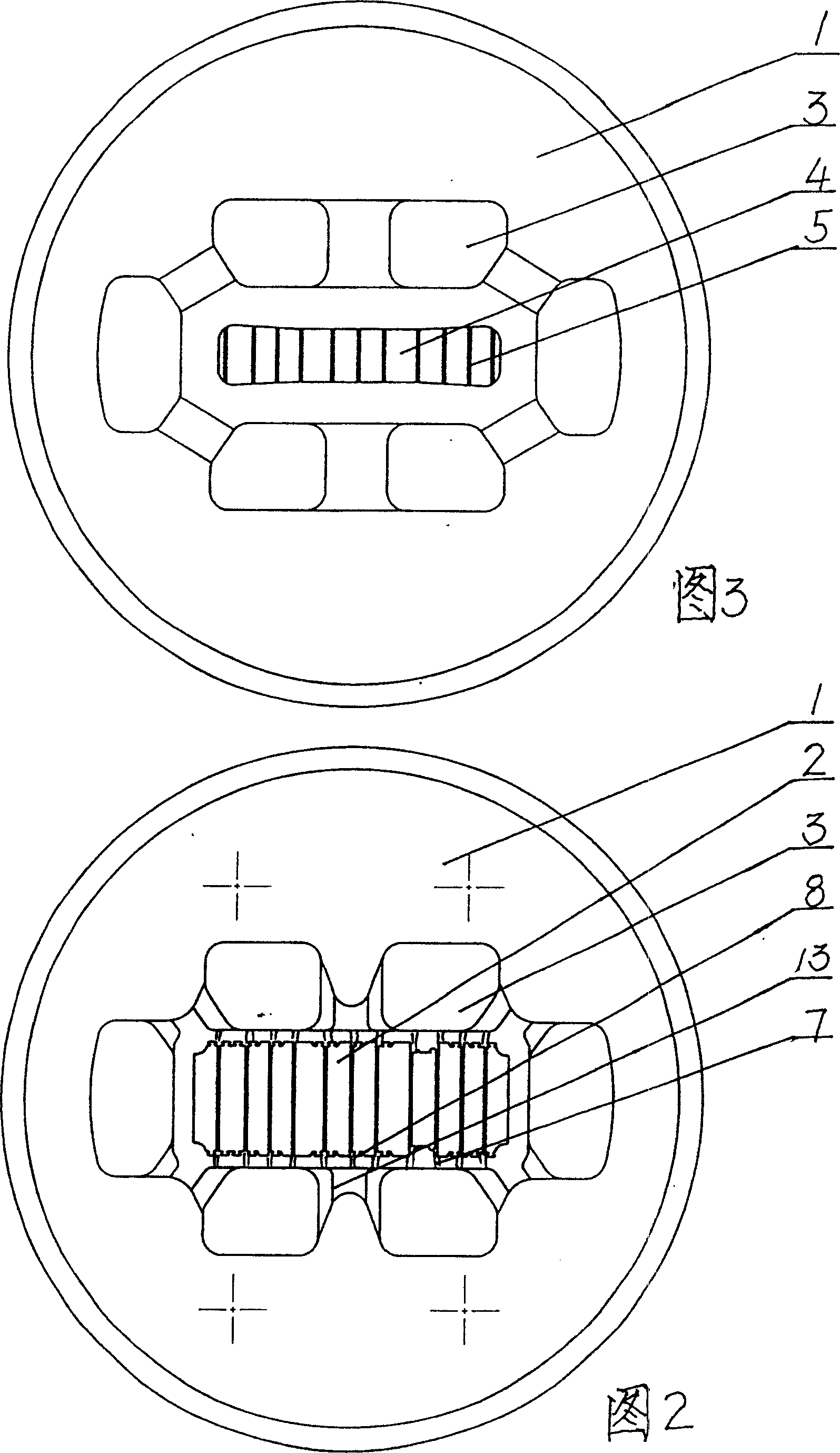

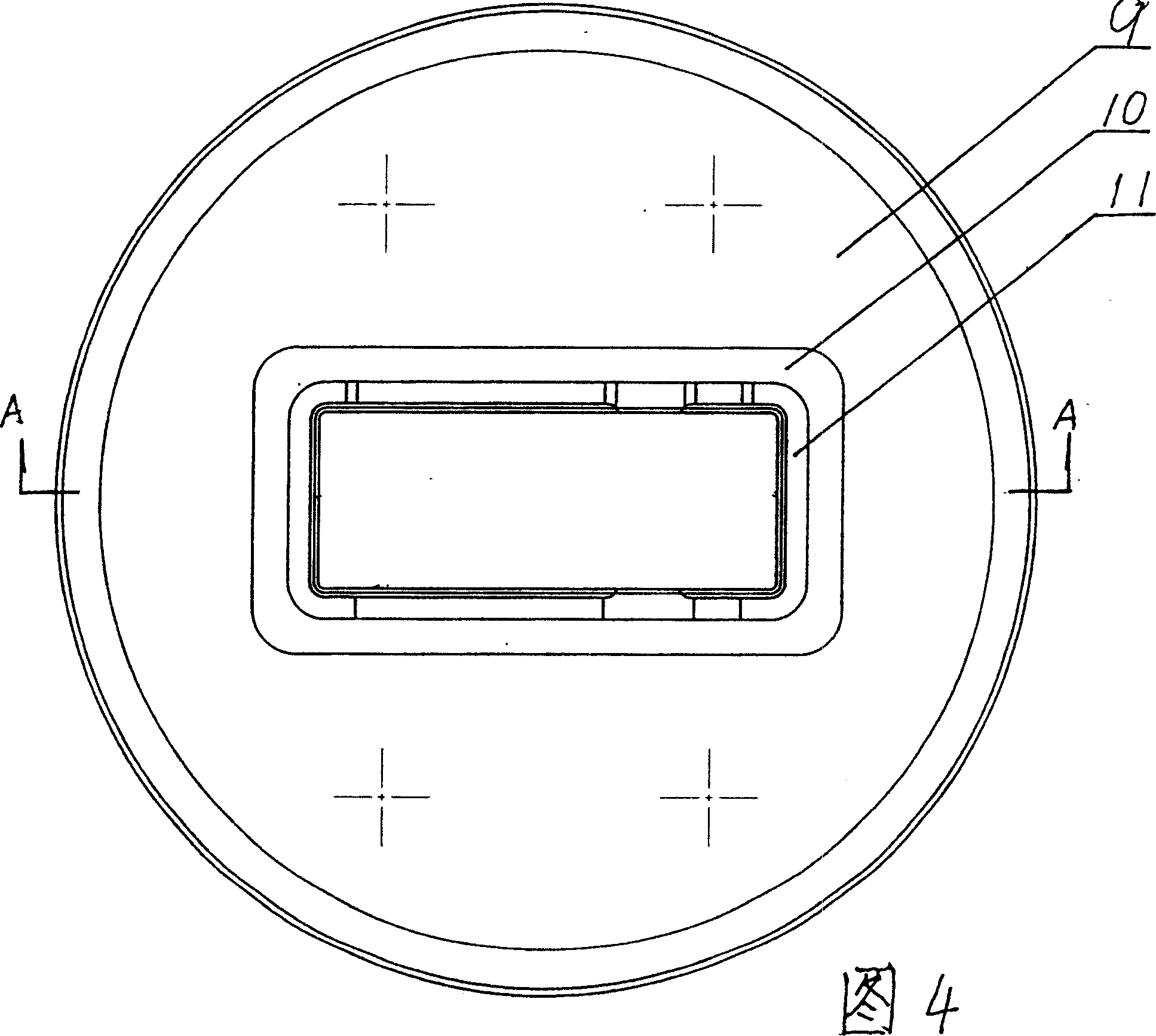

[0015] In order to further understand the characteristics and functions of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with the accompanying drawings, please refer to FIGS. 1-7 .

[0016] As shown in Figure 1: the present invention is a 12-channel shunt combined mold. The heated aluminum alloy billet passes through the shunt hole to produce plastic rheology and then is pressure-welded in the welding chamber to complete the product forming. The mold consists of upper mold 1, The mold core 2 and the middle mold 9 are composed. The upper mold 1 and the mold core 2 are integrated. The center of the upper mold 1 is close to the surrounding of the mold core 2. There are wing-shaped outer shunt holes 3, and the middle of every two adjacent holes is sloped. And it has a drainage arc 13 to guide the flow direction of the metal when it is plastically deformed, which is more conducive to the full filling of the metal, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com