Brake servo unit comprising an emergency brake auxiliary function

A technology of brake booster and control valve, applied in the direction of brake, brake transmission, transportation and packaging, etc., can solve the problems of low cost and complex mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

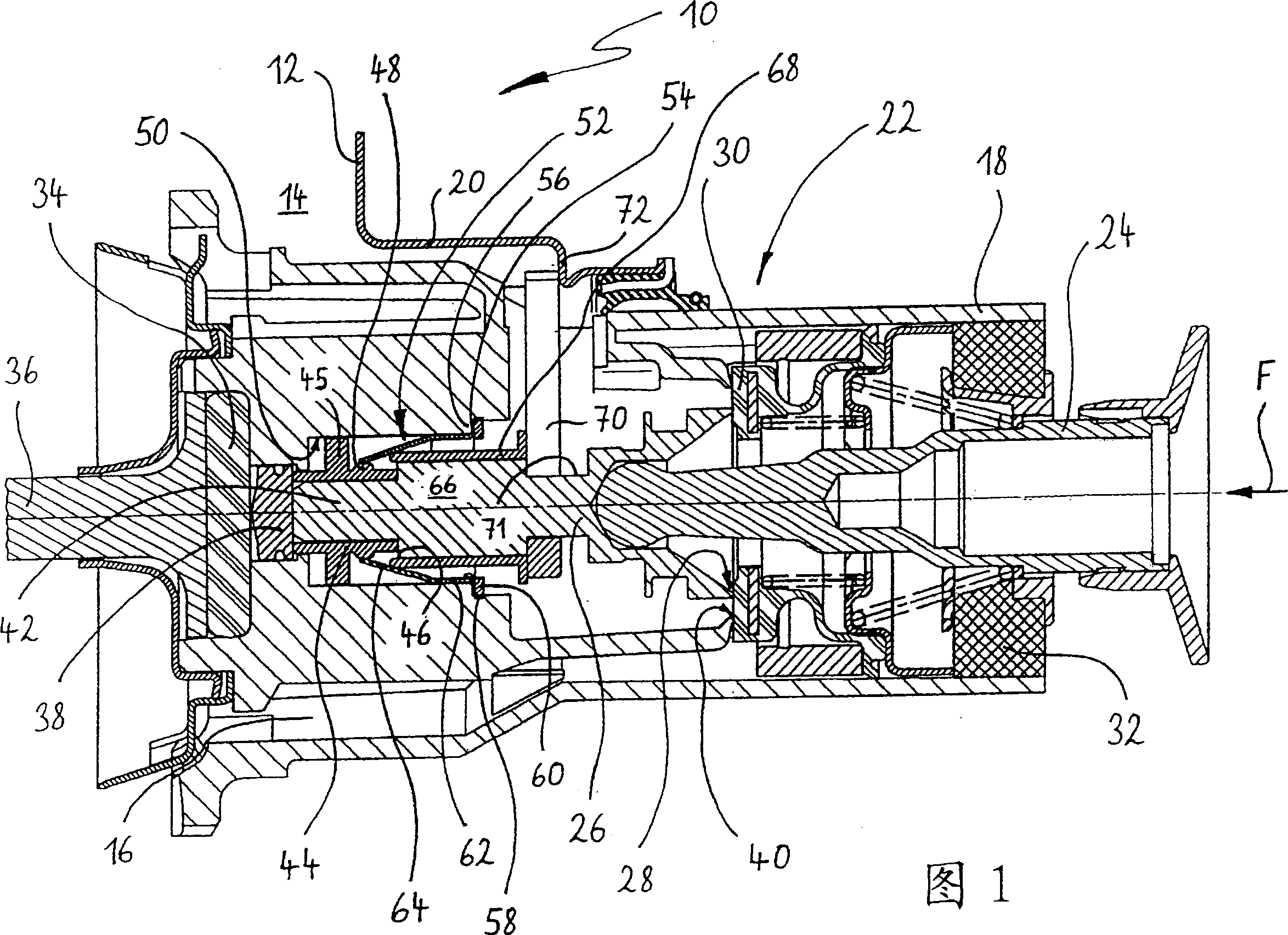

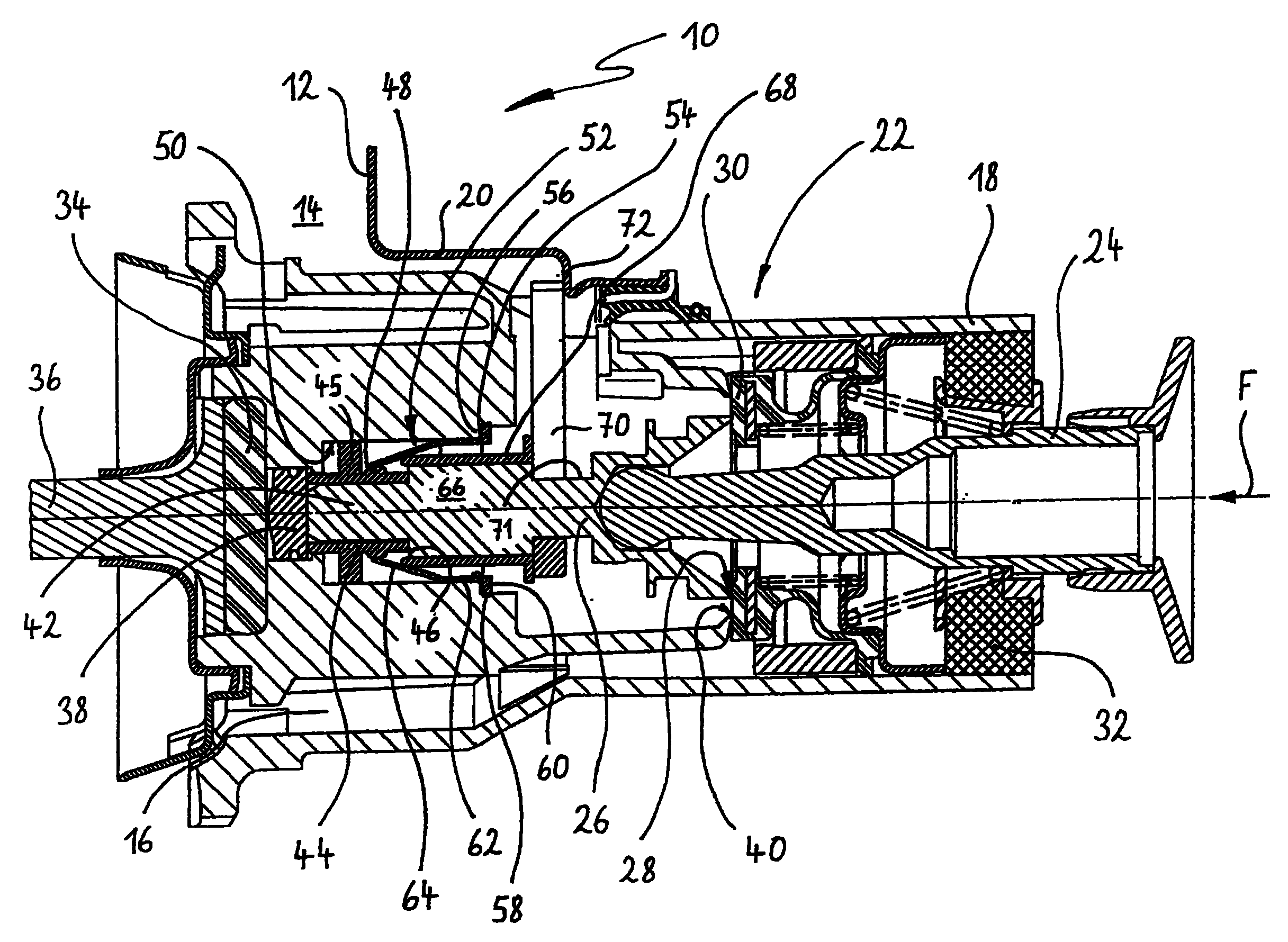

[0017] Hereinafter, an embodiment of the brake booster of the present invention will be described in detail with reference to a schematic diagram, which shows a longitudinal sectional view of the control valve of the brake booster according to the present invention.

[0018] The drawing is a longitudinal sectional view showing relevant parts of a vacuum brake booster used in a hydraulic brake system of a motor vehicle, and the vacuum brake booster as a whole is denoted by the reference numeral 10. A brake master cylinder (not shown in the figure) is connected downstream of the brake booster 10, and the brake booster 10 has a shell 12 composed of a metal plate shell. Only the initial part of the shell 12 is shown in the figure. In the housing 12, a movable wall not shown in the figure seals the working chamber 14 and the vacuum chamber 16 apart.

[0019] The movable wall is firmly connected to the control valve housing 18 which extends in a slidably movable manner within the tubula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com