Synchronous device for double clutch speed variator

A dual-clutch transmission and synchronizing device technology, applied in the direction of transmission, control, transmission control, etc., can solve the problems of no setting, troublesome, expensive, etc., and achieve the effects of economy and wear, reduce wear and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

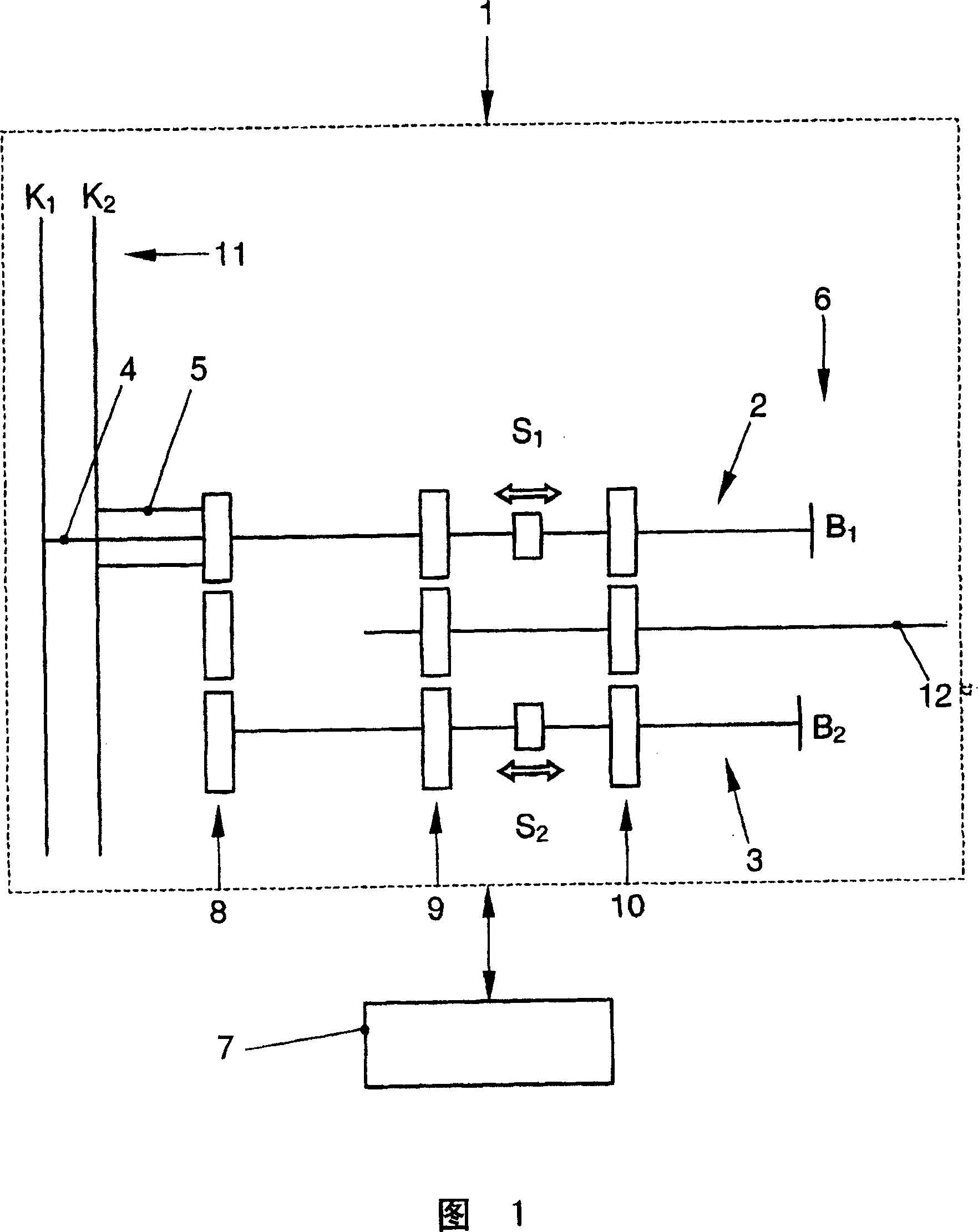

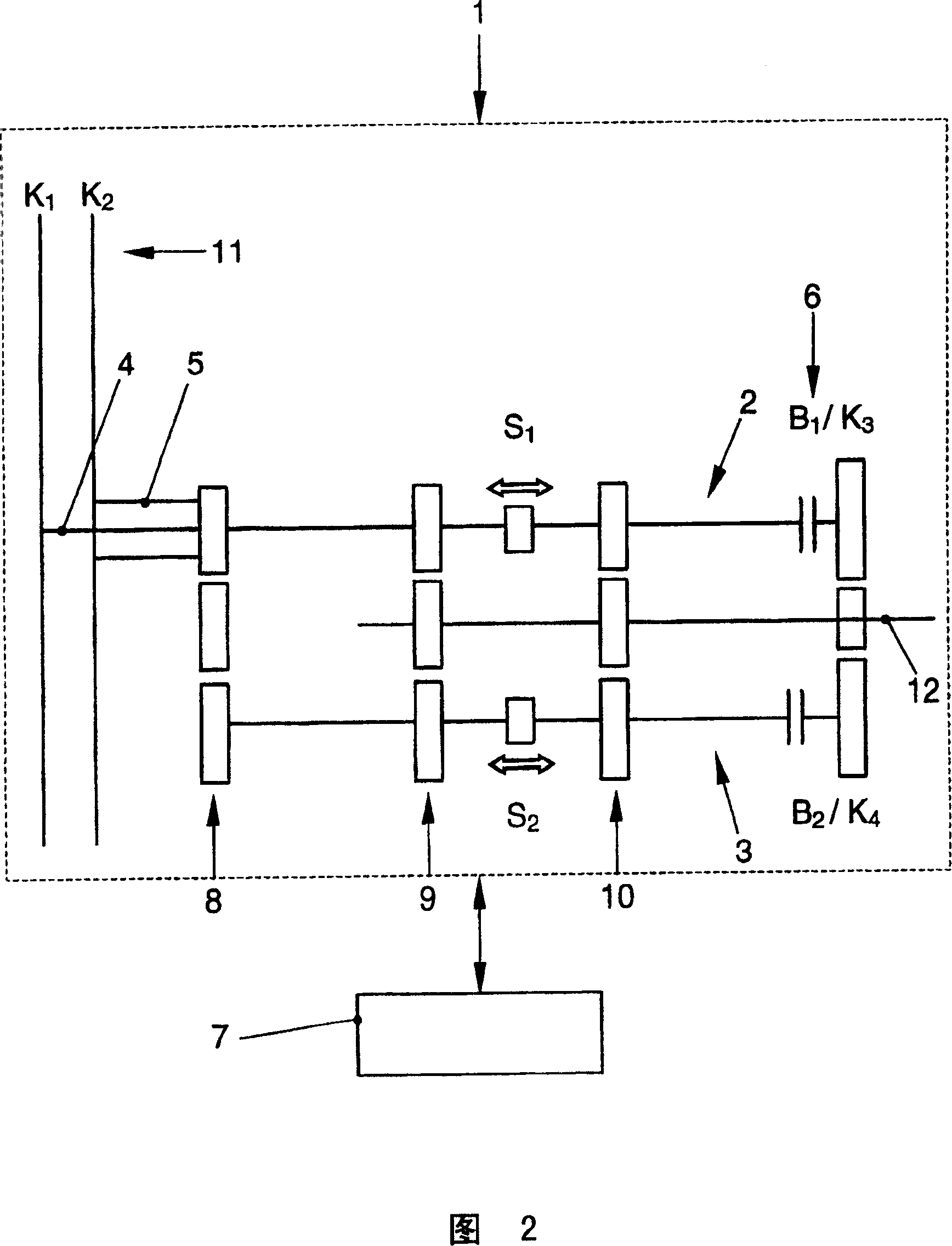

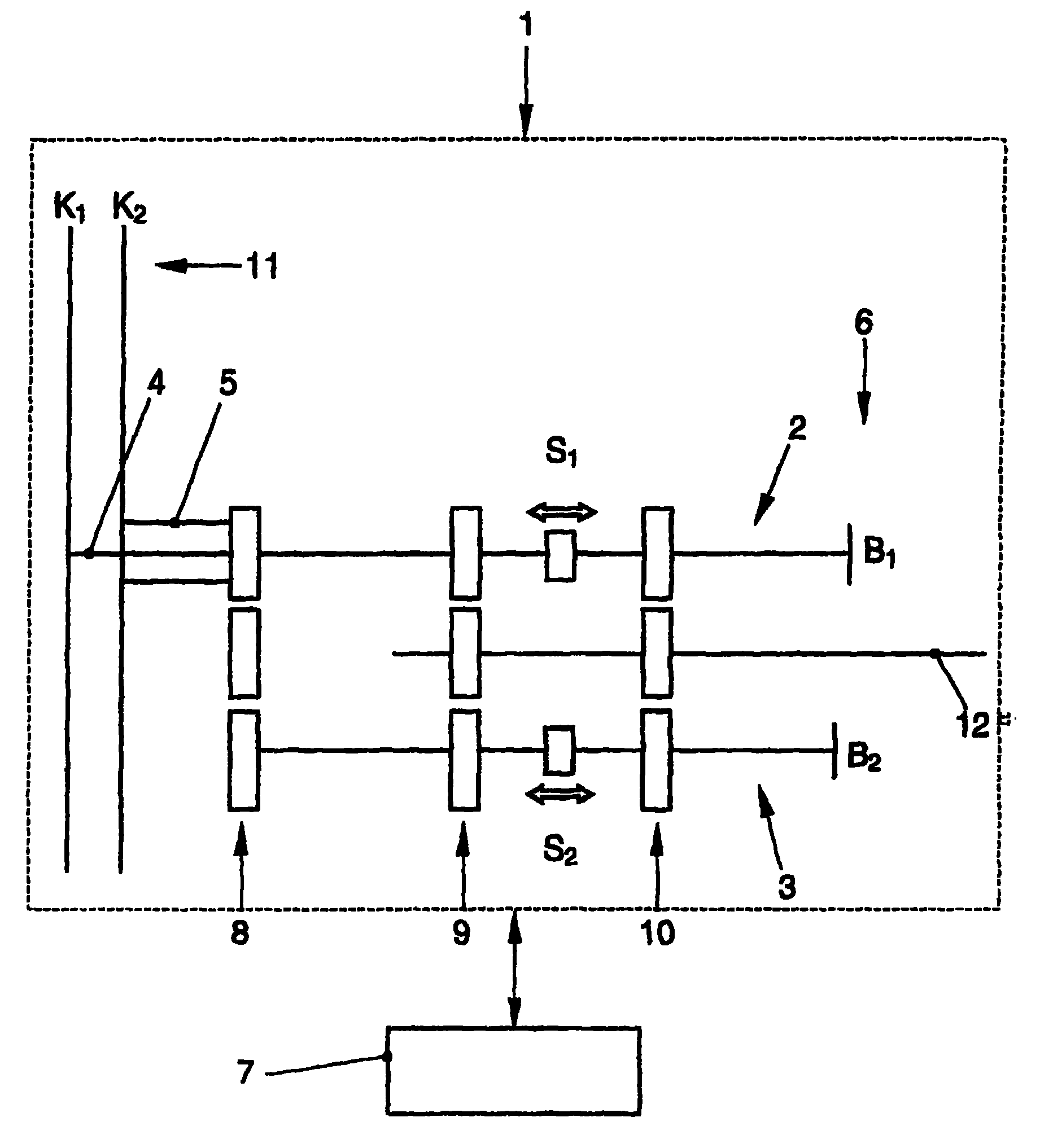

[0028] The synchronizing device 1 of the dual-clutch transmission mainly includes a braking mechanism 6 and two transmission output shaft brakes B1 and B2.

[0029]The dual clutch transmission 1 essentially comprises two subtransmissions 2 and 3 and a dual clutch 11 formed from two input clutches K1 and K2. The subtransmissions 2 and 3 are each connectable via their corresponding input clutches K1 or K2 to a drive motor (not shown) in order to transmit the drive torque via the individual gears, that is to say with a certain transmission ratio, to the transmission output shaft 12 . One sub-transmission 2 or 3 assumes odd-numbered gears, and the other sub-transmission 3 or 2 correspondingly assumes even-numbered gears. The dual-clutch transmission 1 has two coaxially arranged transmission input shafts 4 , 5 , wherein the sub-transmission 2 is assigned to the inner shaft 4 and the sub-transmission 3 is assigned to the outer shaft 5 . Here, the subtransmission 3 is engaged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com