Composite cylinder pressurizing ink-joiner

A pneumatic pressurization and cylinder technology, applied in printing and other directions, can solve the problems of fragile ink cartridges, broken ink, high price, etc., and achieve the effects of reducing office costs, reducing pollution, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

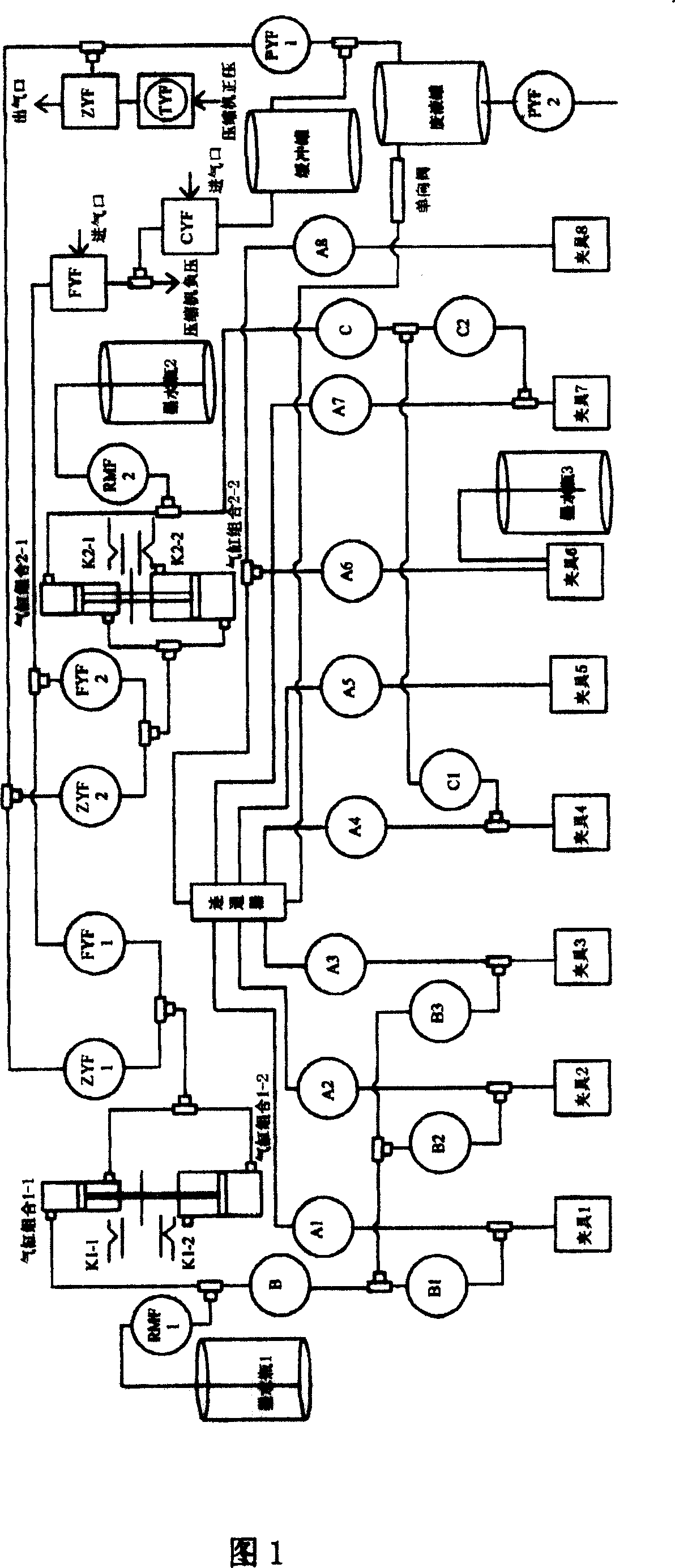

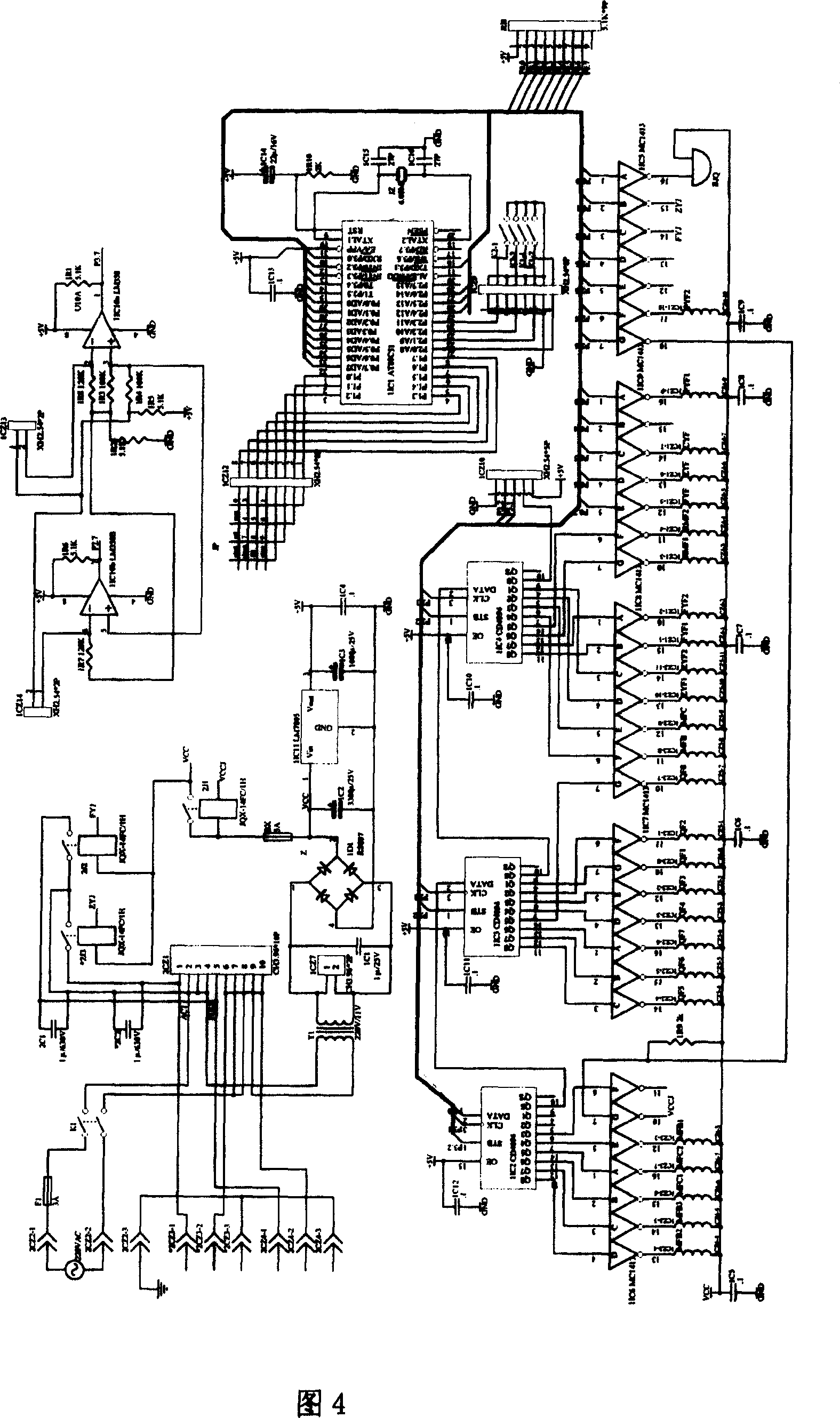

[0018] As shown in Figures 1, 2, and 3, the structure of the air circuit and ink circuit of the combined cylinder pressurized ink filling machine.

[0019] FIG. 1 is an embodiment designed according to the technical solution provided by the present invention. The embodiment includes the core technology of the invention and also applies the prior art.

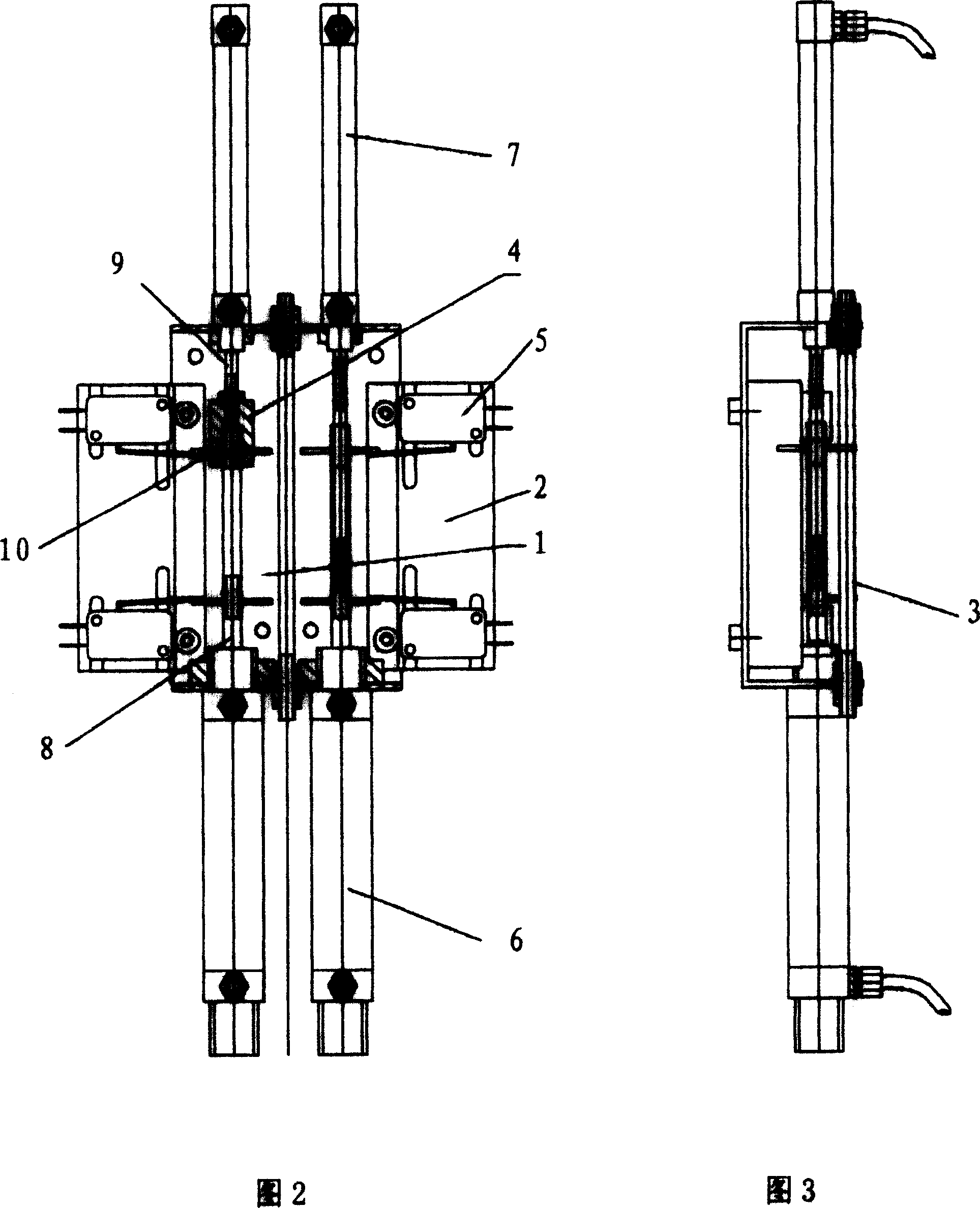

[0020] The core of the pneumatic pressurized ink supply system is the combined cylinder structure, which is composed of two pairs of large and small cylinders 6 and 7 with different displacements. The two ends of the plate 1 are supported and reinforced by the reinforcing screw 3, and the rod ends of the cylinder piston rods 8 and 9 of the large and small cylinders 6 and 7 are butted together and fastened into one with the connecting nut 4. The connected piston rods 8 and 9 are connected to each other. The connecting nut 4 of the part is equipped with a circular travel limit block 10, two switch fixing plates 2 are fixedly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com