Chemical canchoring adhesive rope

An adhesive and anchoring technology, which is applied in the direction of adhesive type, adhesive, film/sheet adhesive, etc., can solve the problem of leaking out and drifting out with the wind in horizontal drilling, insufficient viscosity, multiple Packaging waste and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

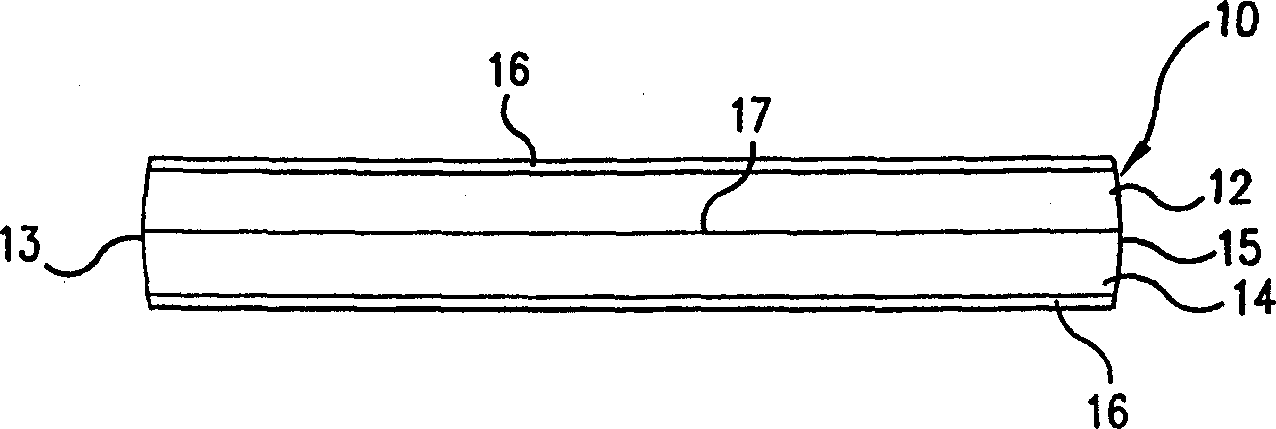

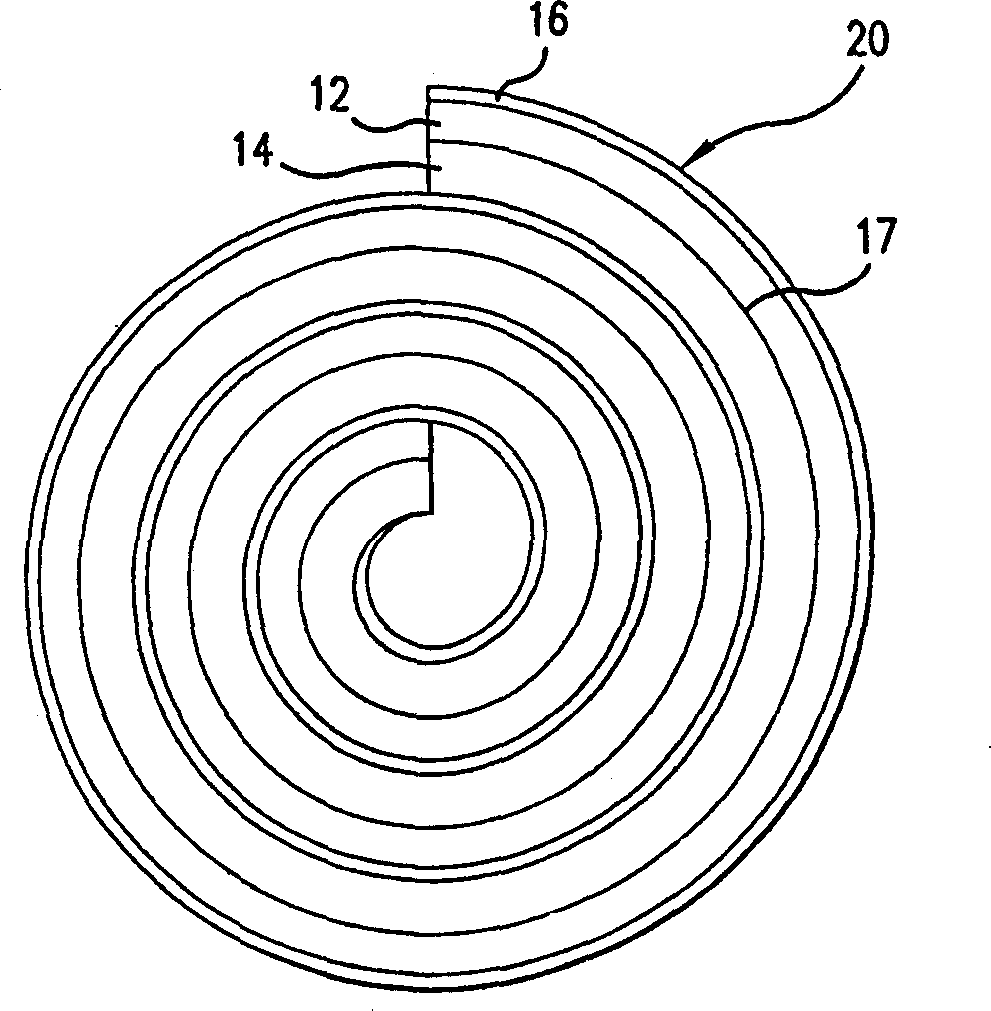

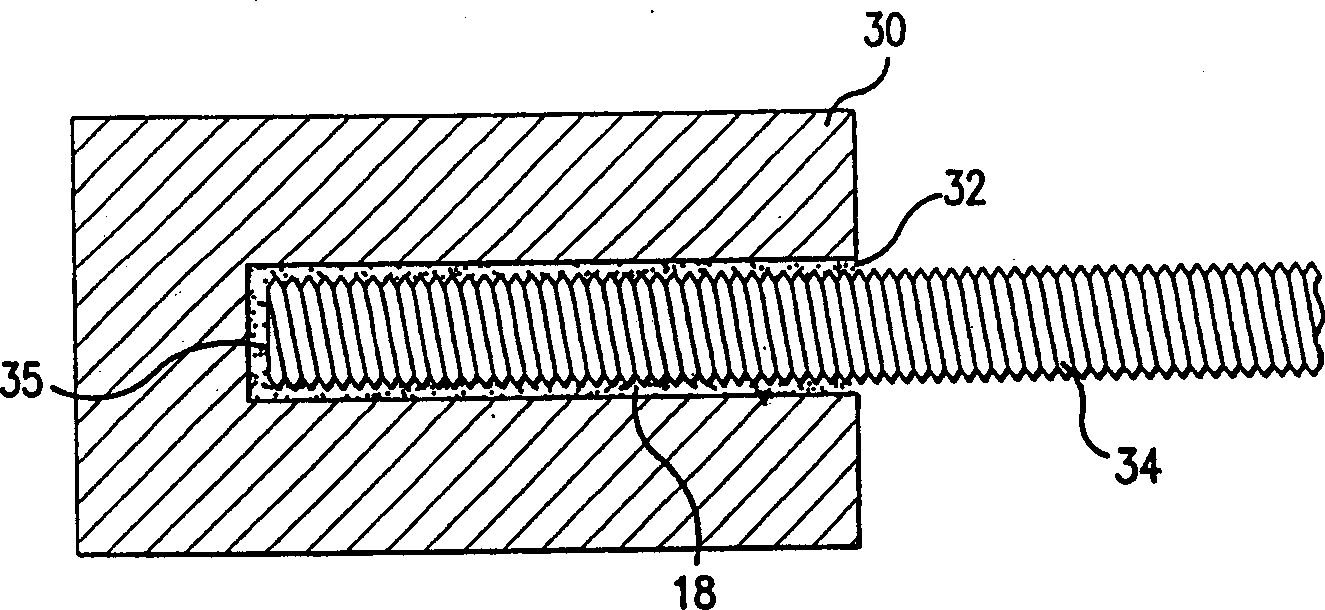

[0022] The invention relates to a chemical anchoring adhesive rope. refer to figure 2 , the rope 20 may be wound into a roll for storage and uncoiled for use. Adhesive strand 20 includes a first portion 12 comprising a resinous component and a second portion 14 comprising a curing agent, the two portions being joined to and contacting each other along a junction 17. The cord 20 is wound together with the film 16 around its periphery.

[0023] The cord 20, when uncoiled and stretched in a straight line, should have a length to diameter ratio of at least about 4, preferably at least about 10, and more preferably at least about 15. The rope 20 may have a cylindrical or elliptical cross-section (preferably having a cross-section as shown in FIG. 4( a)) as shown in FIGS. A multi-strand line (threaded) cross-section of adjacent fine lines, a square or rectangular cross-section as shown in Figure 4(e) to 4(g), a triangular cross-section as shown in Figure 4(h), as shown in Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com