Construction technology without detaching forms for concrete

A concrete and formwork-free technology, which is applied to building components, walls, buildings, etc., can solve problems such as large vibration and noise, environmental pollution, and disturbing residents, and achieve the effect of low construction cost and high construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

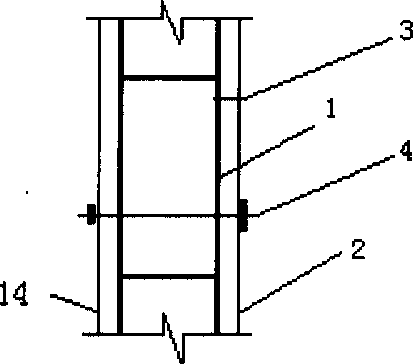

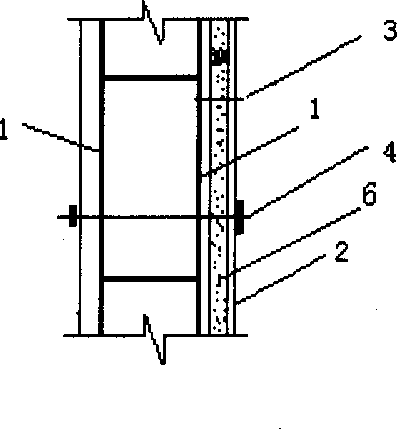

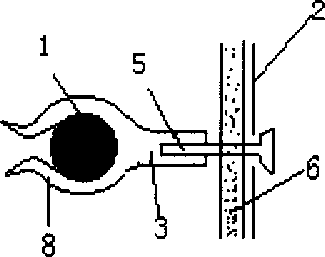

[0014] Fix the steel mesh 2 and the steel mesh 14 on the outer side of the bound steel frame 1 with the fixing part 3 composed of the clip 8 and the fixing screw 5, and use the screw rod 12, the nut 10, the nut 11 and the angle steel 7 and the angle steel 9. The fixing part 4 connects the steel mesh 2 and the steel mesh 14 on both sides, and pours self-compacting and vibration-free concrete into the steel mesh 2 and the steel mesh 14. After the concrete reaches a certain strength, the angle steel 7 and the angle steel 9 on both sides are removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com