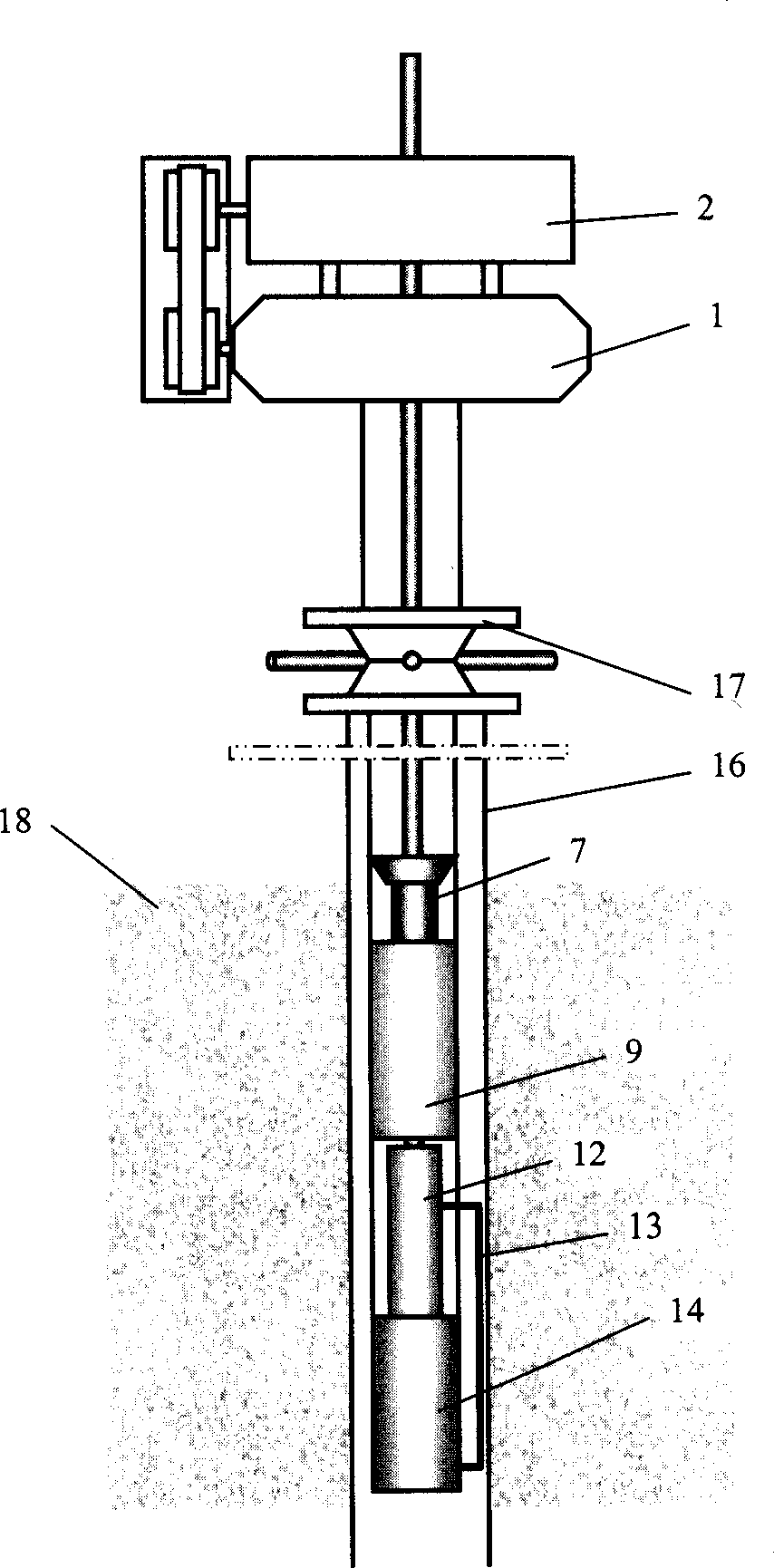

Pumping unit of oil well

A technology for oil pumping and oil wells, which is applied in the field of exploitation of various oil reservoirs, can solve the problems of large energy loss, small application range, and large investment, and achieve the goal of improving production degree and oil recovery speed, reducing labor intensity, and simplifying process procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

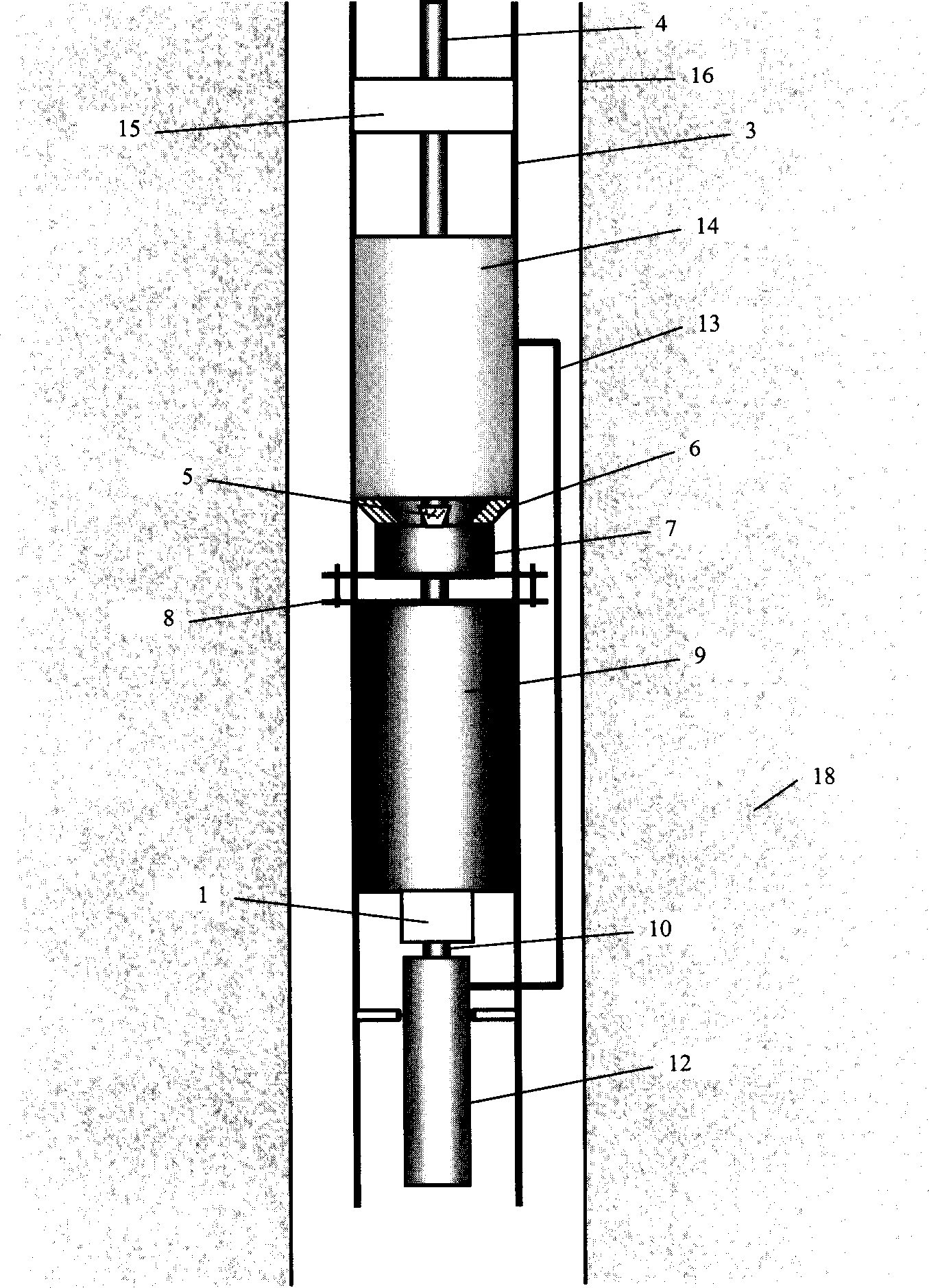

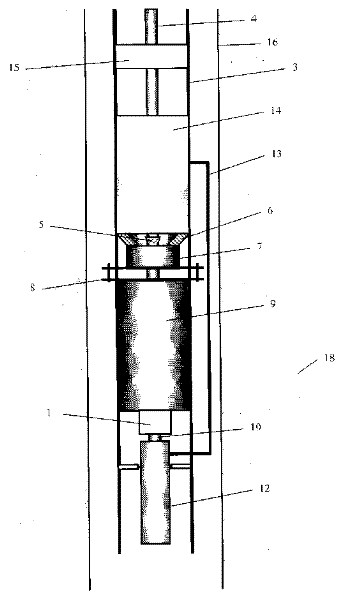

[0018] The various parts that make up the present invention: including harmonic transmission, downhole generator, downhole heater and oil well pump itself are all prior art, in the implementation process, they are positioned at the lower part of the oil pipe in the oil well casing, submerged in the incoming fluid of the oil reservoir. Among them, the harmonic transmission structures commonly seen on the market include inner and outer ring gears, movable ring gears and guides, wherein the inner ring gear is fixed on the driving shaft of the guider, the outer ring gear is fixed on the driven shaft, and the movable ring gear Located in the middle of the inner and outer ring gears, when the modules of the outer teeth and the inner teeth of the movable ring gear are different, the modules of the outer ring gear and the inner gear are also different, and the speed ratio is also different. Modulus change achieves the purpose of speed change. At present, the transmission ratio of dome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com