Spiral window curtain holder

A curtain frame and spiral technology, applied in the field of curtain frames, can solve the problems of large friction force, large rotation driving force, and large pulling force, and achieve the effect of small friction force, small driving force, and light noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

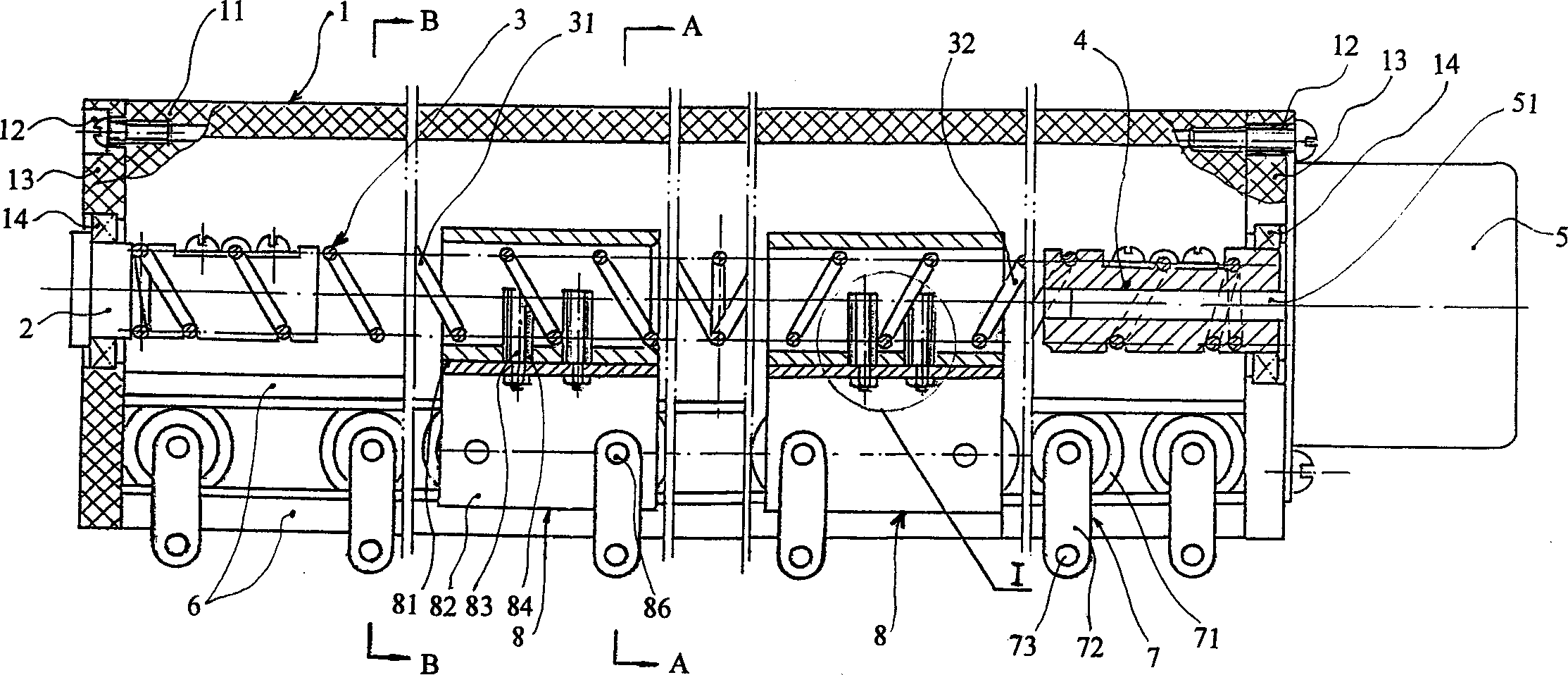

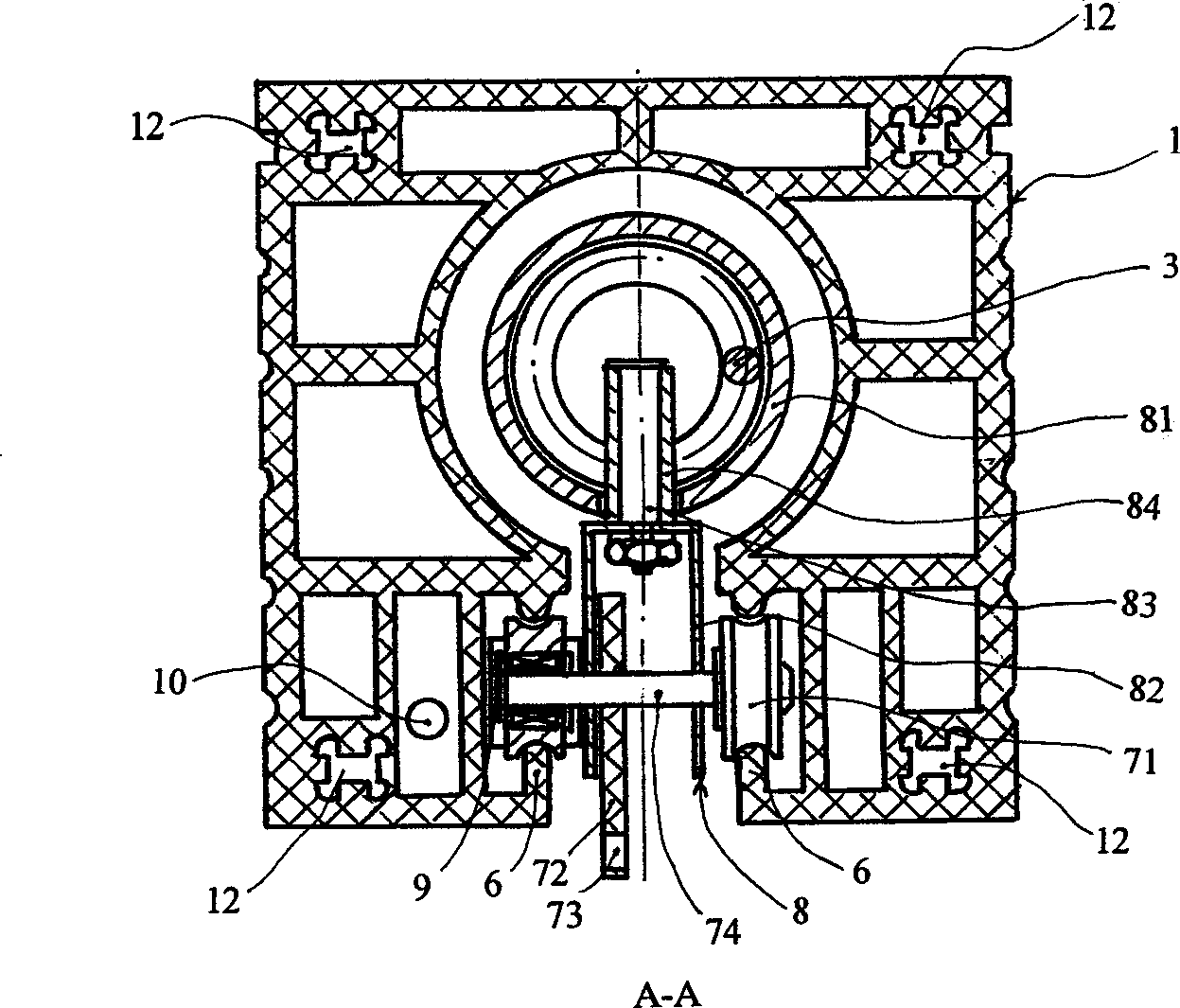

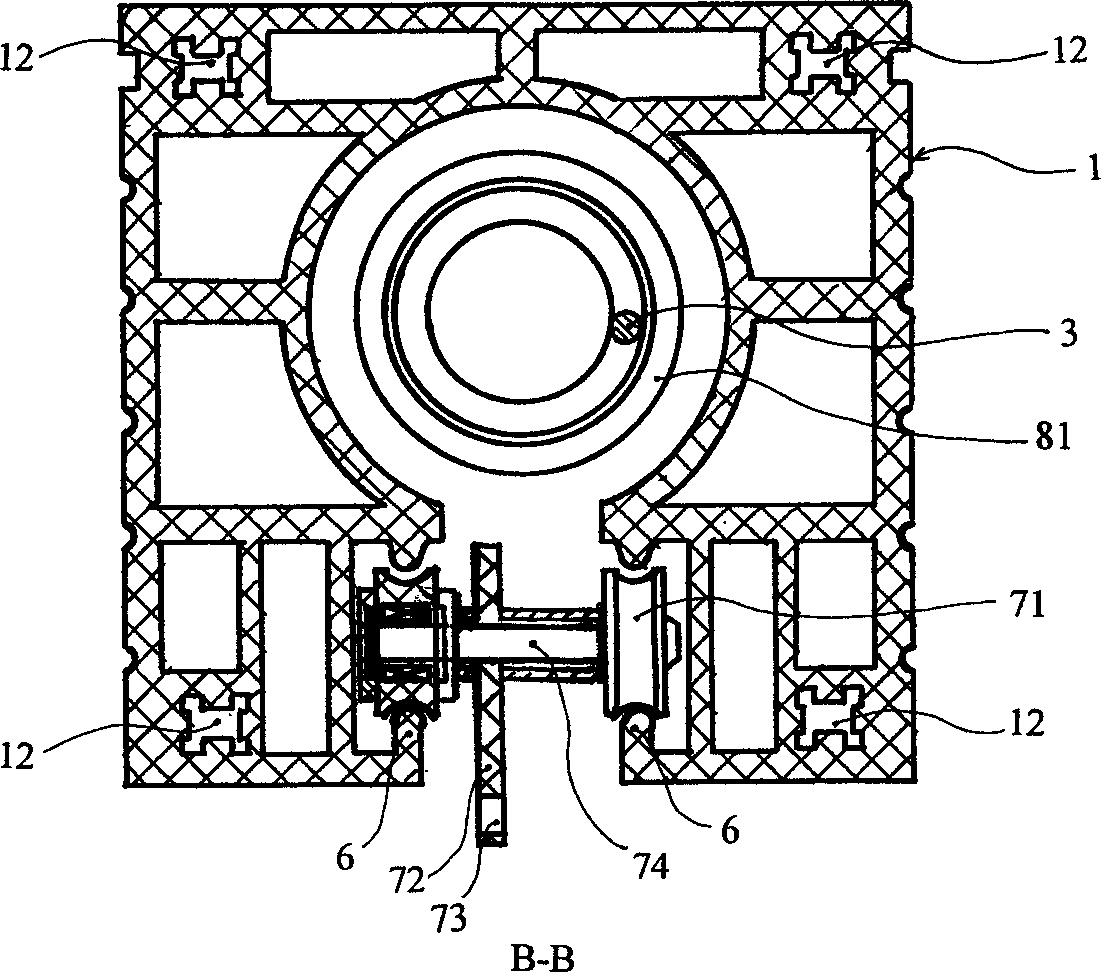

[0018] like Figure 1 ~ Figure 3 As shown, it is an embodiment of an electric rotary curtain frame, including a frame 1, an AC synchronous motor 5 located outside the frame 1, a support 12 with bearings 13 located at both ends of the frame 1, and the two ends are supported by the support 12 The upper and lower spiral steel wires 3 and the slide bar 6 parallel to each other and a plurality of roller-type lifting ring seats 7 arranged on the slide bar 6;

[0019] The spiral steel wire shape 3 is like a spring but is rigid. In this embodiment, it is a two-way spiral, that is, a left-handed steel wire 32 and a right-handed steel wire 31 separated by the middle, which are used for the relative opening and closing of double-width curtains. They are respectively fixed with the linkage shaft 4 and the tightening shaft 2, the linkage shaft 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com