Magnetic head actuator and related gimbal assembly, making method thereof and related magnetic disk drive

An actuator and gimbal technology, applied in the field of magnetic head gimbal assembly, magnetic disk drive, and manufacturing such HGA, can solve problems such as deterioration of magnetic head characteristics, difficulty in obtaining stroke, and reduction of shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

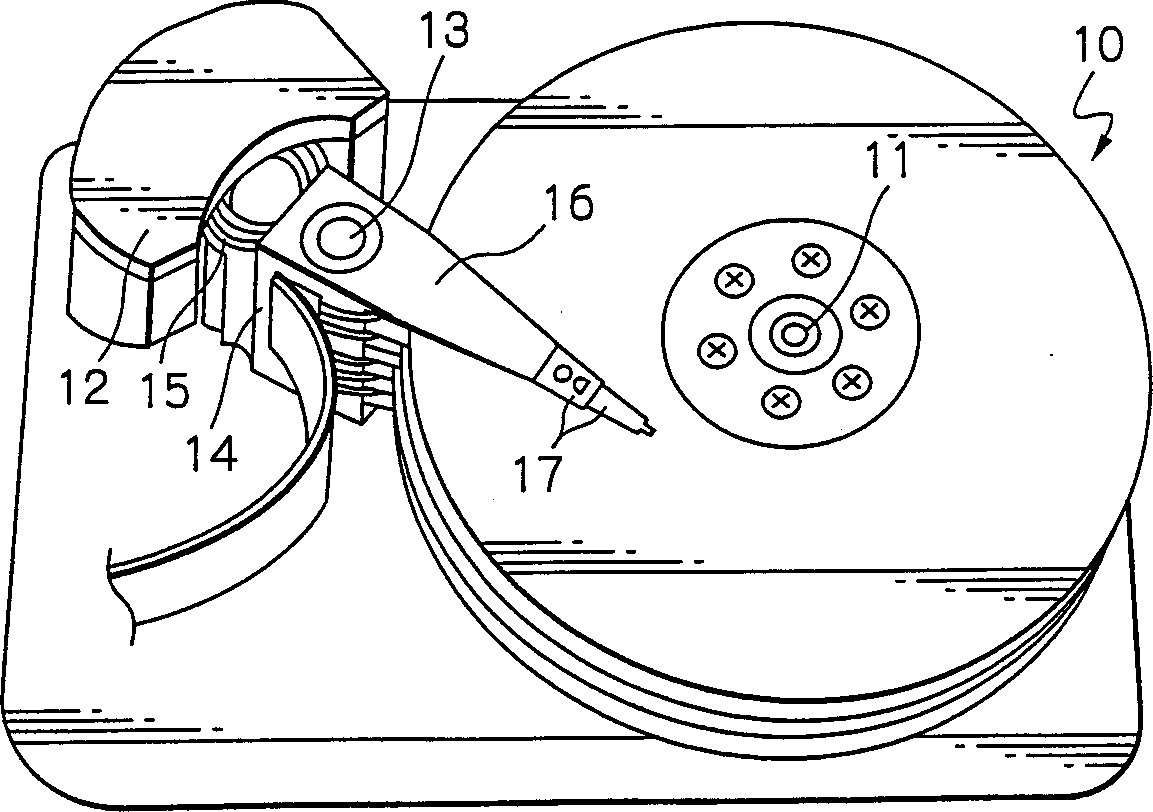

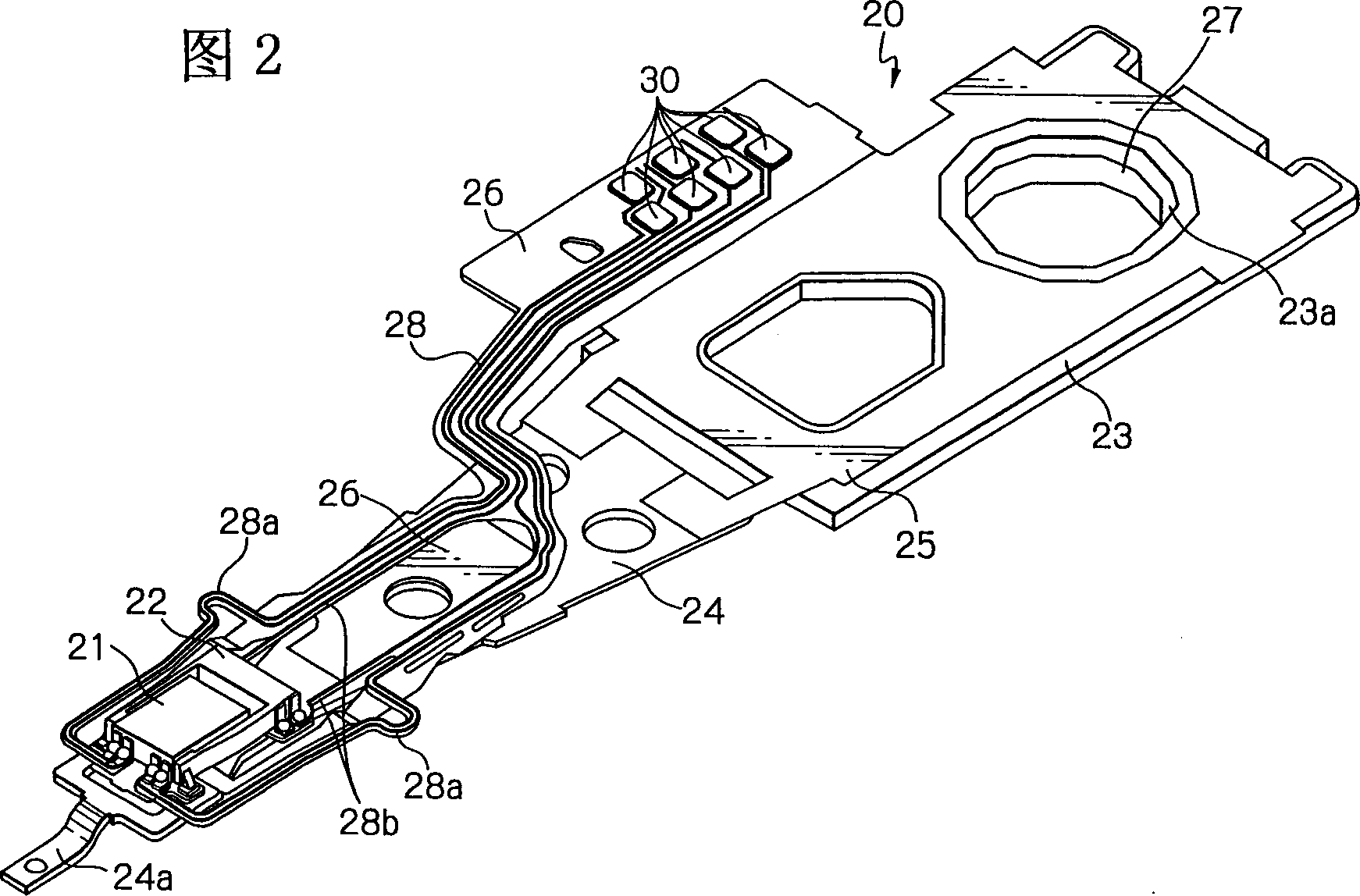

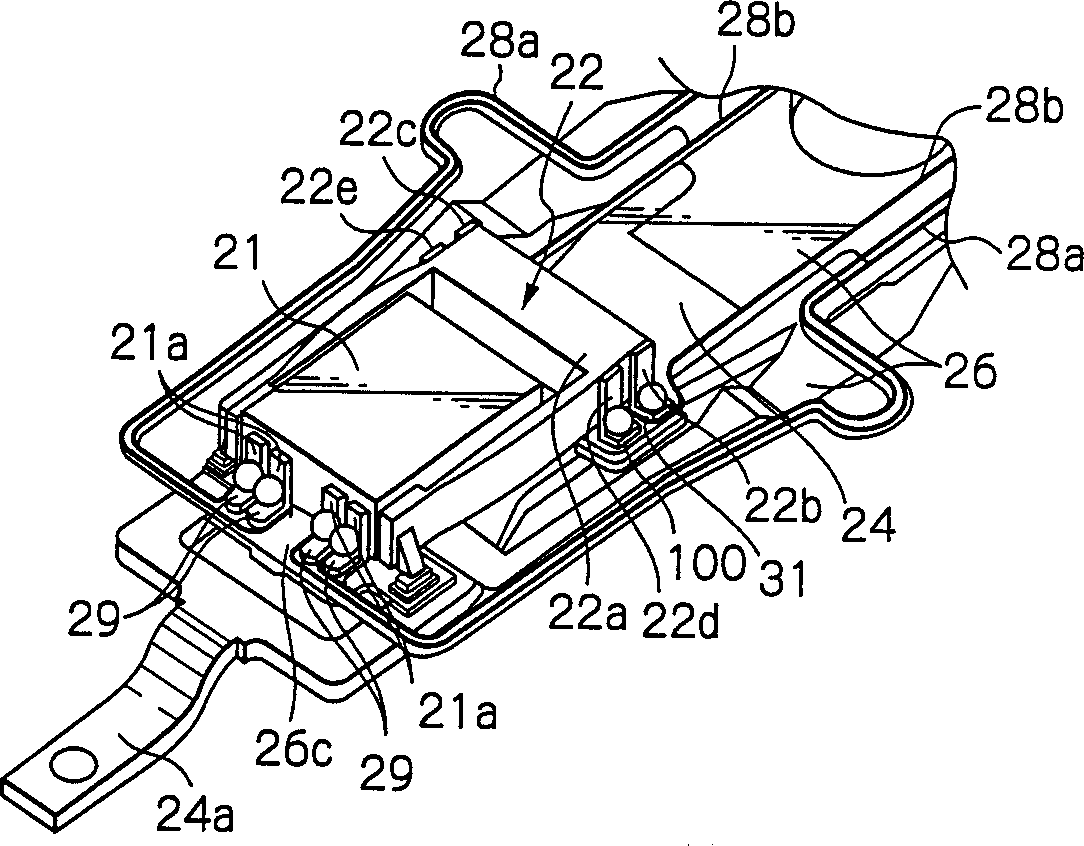

[0050] figure 1 Show the main parts of the preferred embodiment disk unit of the present invention, Fig. 2 shows the whole structure of HGA in this embodiment, image 3 and 4 The top portions of the HGA of this embodiment are shown viewed from different directions from each other.

[0051] figure 1 Reference numeral 10 represents a plurality of hard disks rotating about an axis 11, and reference numeral 11 represents an assembly carriage device for positioning individual magnetic head elements on tracks of individual disks. The assembly bracket device 12 is mainly composed of a bracket 14 that can rotate around an axis 13 and a main actuator 15 such as a voice coil motor (VCM) that drives the bracket 14 to rotate.

[0052] The bottom portion of one end of a plurality of drive arms 16 is stacked along the shaft 13, fixed to the bracket 14, and one or two HGAs 17 are mounted on the top portion of the other end of each arm 16. The top portion of each HGA 17 is provided with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com