Belt for non-stage transmissions

A speed changer and transmission belt technology, applied in V-shaped belts, mechanical equipment, belts/chains/gears, etc., can solve the problems of reduced durability, uneven contact, and partial wear of metal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

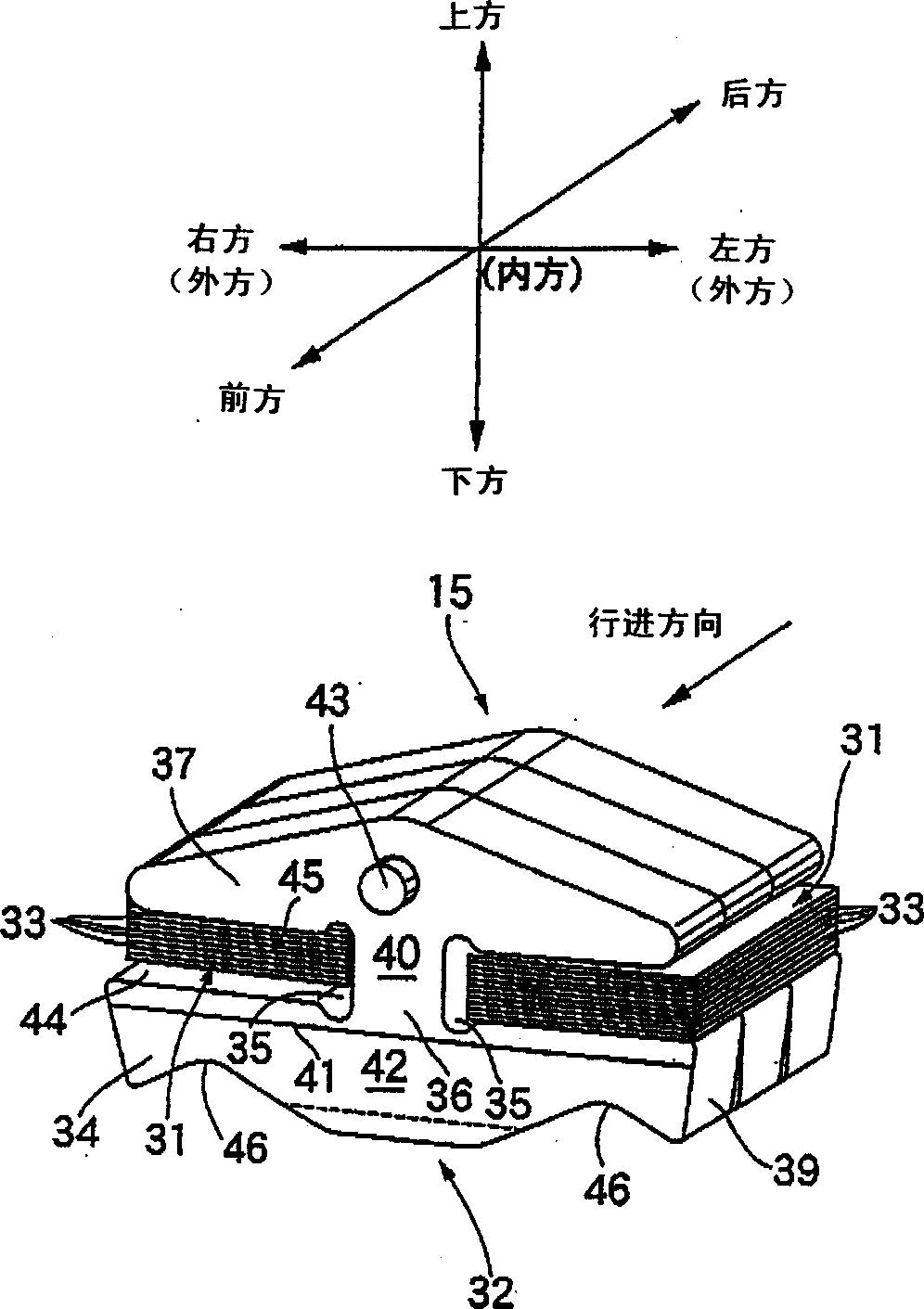

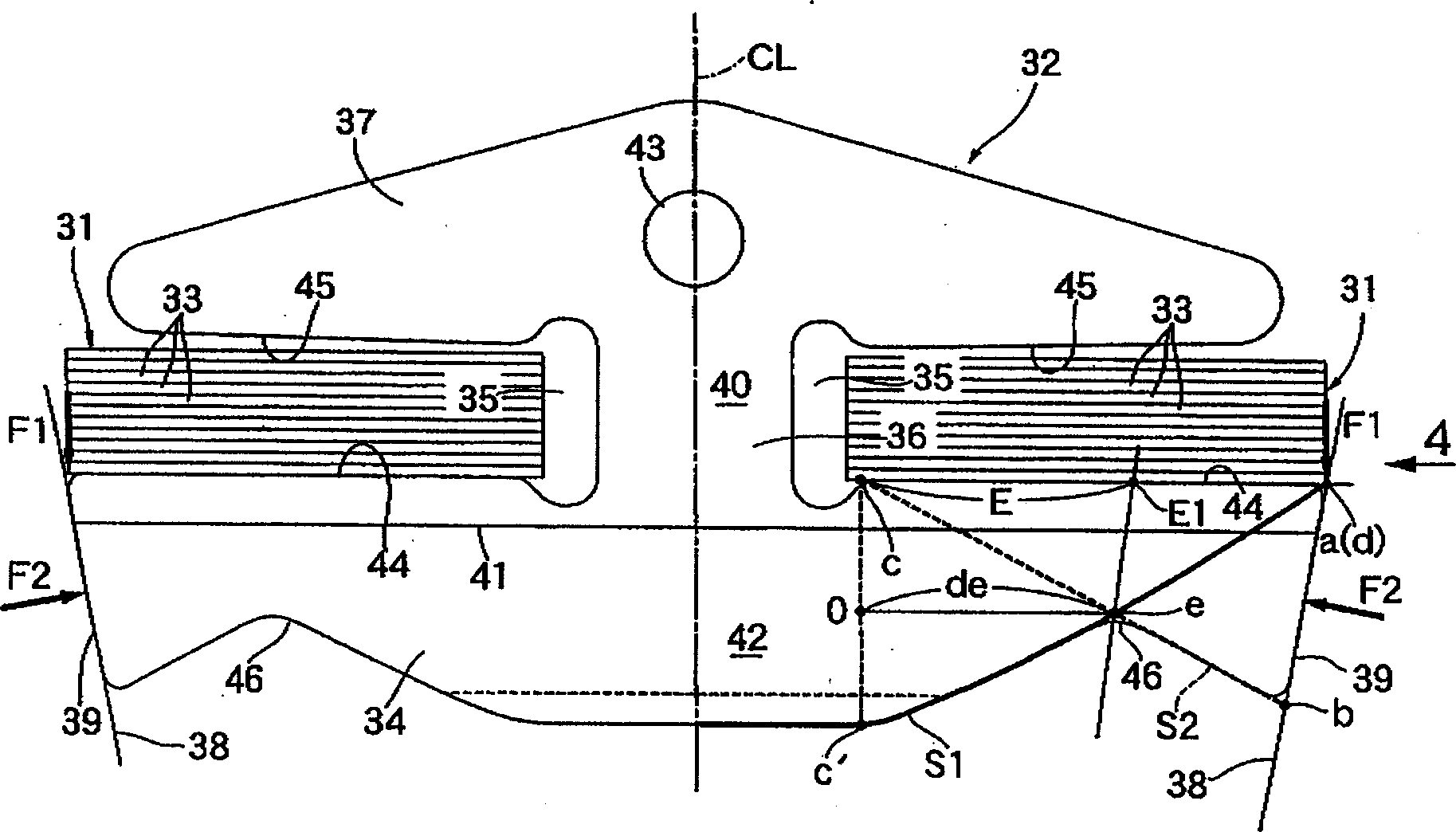

[0010] Embodiments of the present invention will be described below with reference to the embodiments of the present invention shown in the accompanying drawings.

[0011] Figures 1 to 10B An embodiment of the present invention is shown.

[0012] In addition, the definitions of the front-rear direction, the left-right direction, the up-down direction, and the inner-outer direction of the metal element used in this embodiment are as follows: figure 2 shown.

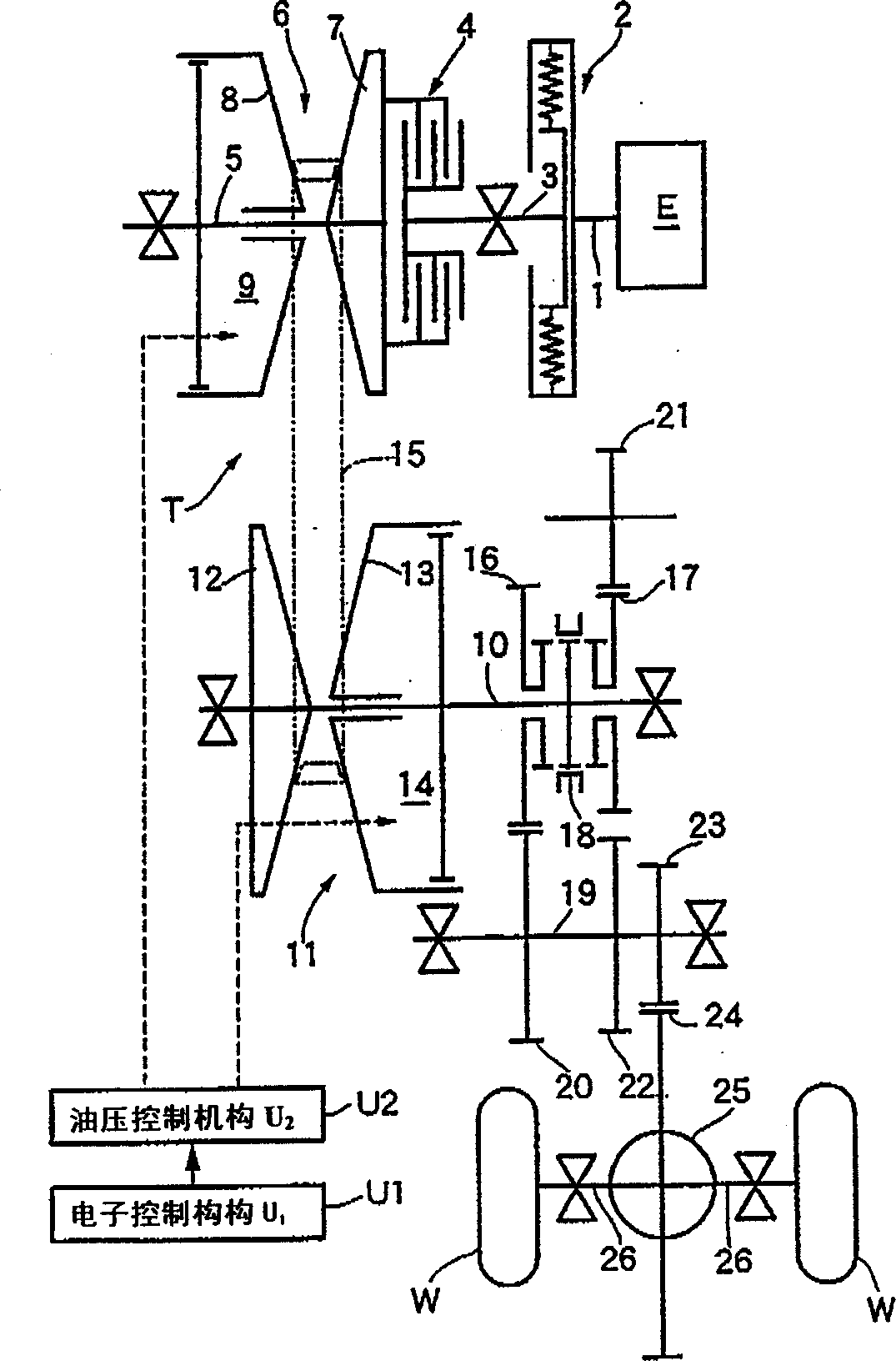

[0013] figure 1 The schematic structure of a metal belt continuously variable transmission T mounted on an automobile is shown. The input shaft 3 connected to the crankshaft 1 of the engine E via the shock absorber 2 is connected to the drive shaft 5 of the metal belt type continuously variable transmission T via the starting clutch 4 . The drive pulley 6 provided on the drive shaft 5 includes a fixed-side pulley half body 7 fixed to the drive shaft 5 , and a movable-side pulley half body 8 that is attachable to and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com