Method for compensating mechanical vibration in machine

A mechanical vibration and machine technology, applied in mechanical vibration control, general parts of printing machinery, mechanical equipment, etc., can solve problems such as hidden measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

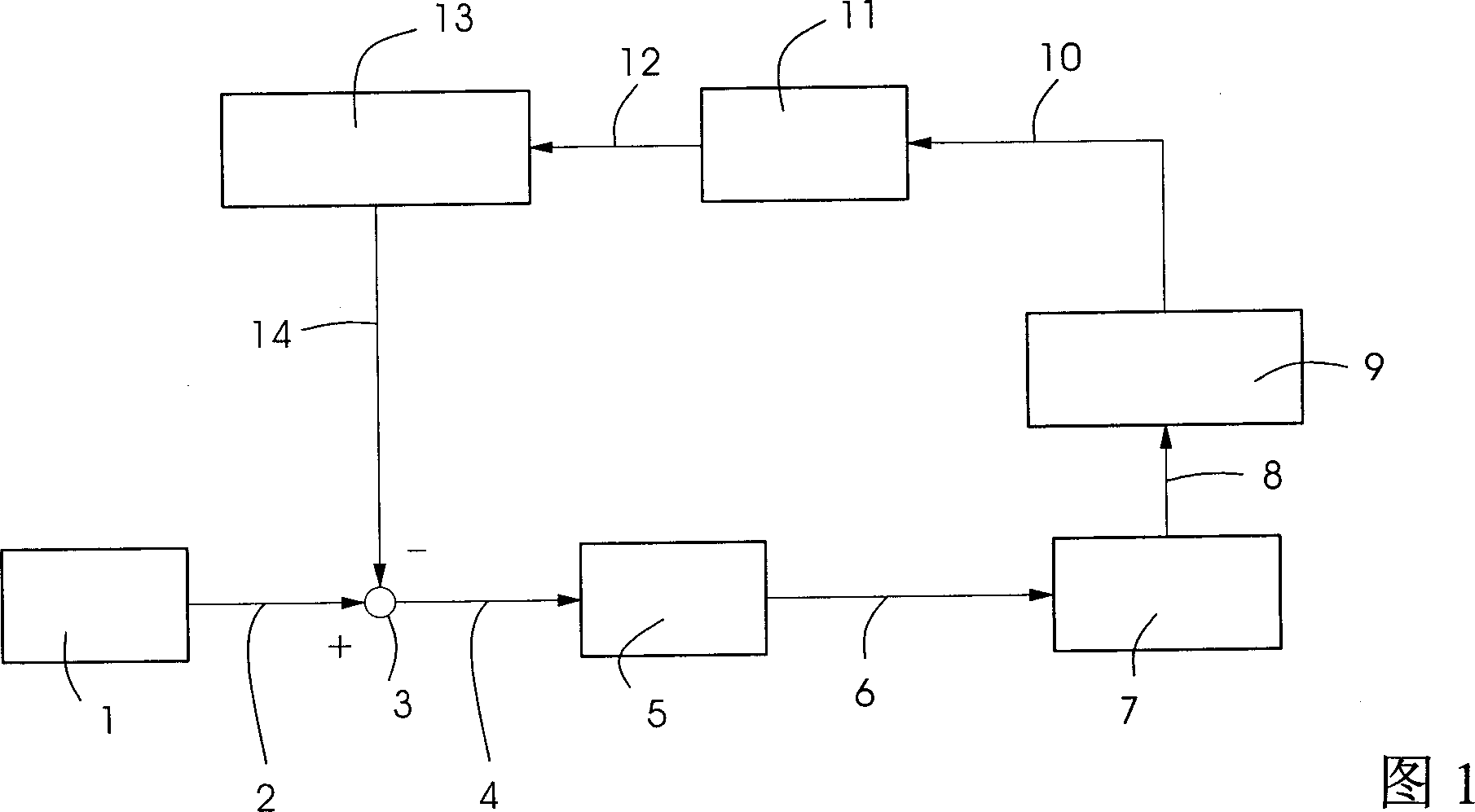

[0031] The printing machine of the present invention and the working steps of the method of the present invention will be described in detail with reference to FIG. 1 and subsequent embodiments. Without loss of generality, it is shown that for a certain circular frequency ω s or compensation for mechanical vibration or disturbance of a machine shaft of machine frequency order r, where r is a real number. Because for a certain circular frequency ω s The compensation of the mechanical vibration or disturbance is carried out in a manner independent of other circular frequencies or orders, the so-called superposition principle, so this method can especially be used for any number of different circular frequencies ω si or order r i Compensation is performed, where i is a natural number, and the method can be used both simultaneously and sequentially. This makes it possible for the machine shaft to turn at a constant speed even when non-uniform moments act on it.

[0032] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com