Construction method of concrete pile

A technology of concrete piles and construction methods, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of mutual influence of adjacent piles, easy disengagement of pile bottoms, ground uplift, etc., to achieve integrity enhancement, avoid Out of joint, to avoid the effect of diameter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

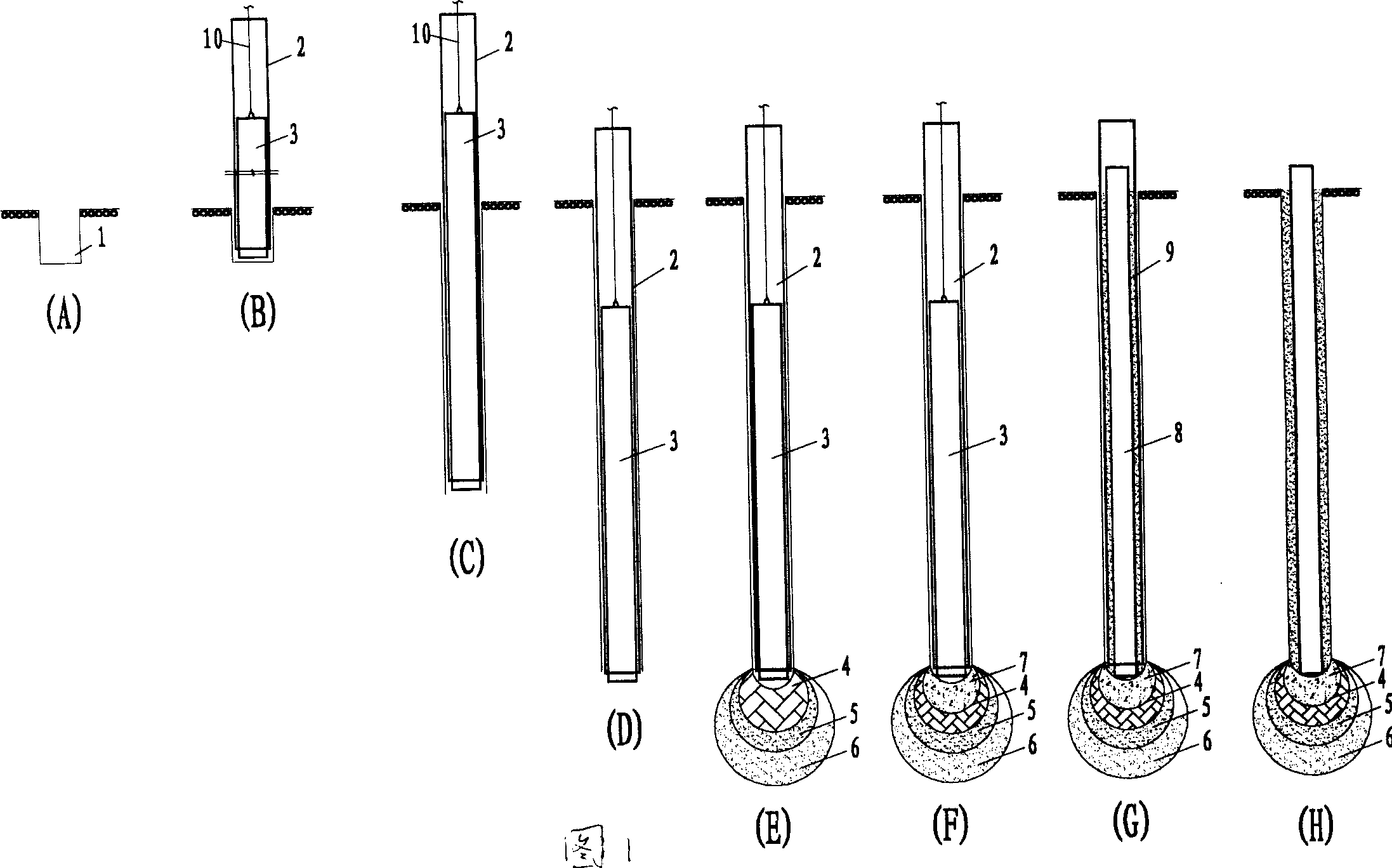

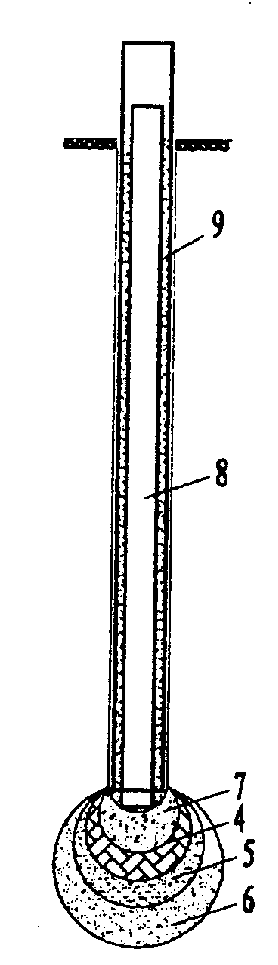

[0021] The construction method of the concrete pile of the present invention will be described below with reference to the accompanying drawings through the embodiments.

[0022] Fig. 1 is a process diagram of an example of a method for constructing a concrete pile according to the present invention.

[0023] First, calculate the initial design pile length according to the geological exploration report, then, as shown in Figure 1(A), at the selected pile position, carry out the construction of the lead hole by digging hole 1, and then, as shown in Figure 1(B), place the Stand up the casing 2, insert its bottom end into the above-mentioned dug hole to realize the positioning of the casing 2, and then, as shown in Figure 1(C), carry out tamping and pipe construction by lifting and lowering the rammer 3, Make the above-mentioned casing 2 gradually enter the foundation, and then, as shown in Figure 1(D), sink the above-mentioned casing to the design elevation according to the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com