Process for producing basic cell by uisng nano indium hydroxide

An indium hydroxide, alkaline battery technology, applied in the direction of alkaline battery electrodes, primary battery electrodes, battery electrodes, etc., can solve the problems of battery potential difference, poor battery leakage resistance, short storage time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

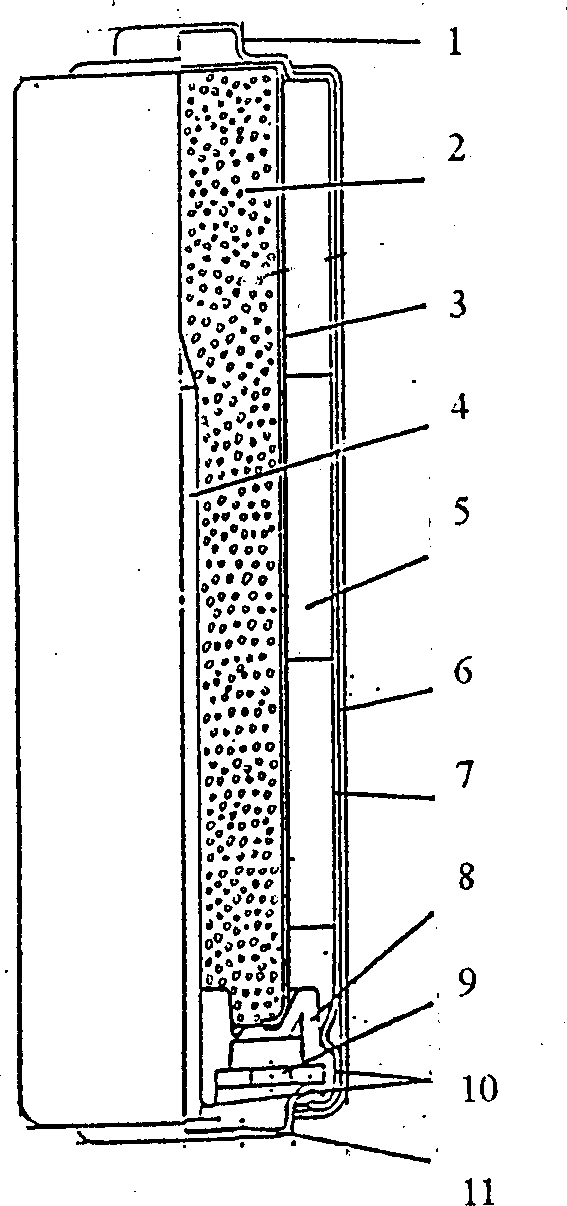

[0017] Utilize the alkaline battery produced by the present invention, its structure and main process are basically the same as the prior art. Such as: figure 1 The battery structure in the battery is the same as the current battery structure, 1 is the positive electrode; 2 is the zinc paste; 3 is the spacer; 4 is the copper nail; 5 is the powder ring; 6 is the trademark; 9 is an auxiliary plate; 10 is a sealing glue; 11 is a negative pole. The uniqueness of the present invention lies in that nanometer indium hydroxide is added in the production process of the negative electrode material zinc paste. The process seems simple, but the overall performance of the battery has been greatly improved. The nano-indium hydroxide (In(OH) 3 ) is produced by Hunan Keyuan Technology Industrial Co., Ltd. (the factory is located at Jianguo Road, Changsha City). The production process, performance indicators and various test reports of this product belong to the existing technology and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com