Fixture for laser welding

A laser welding jig and clamping device technology, which is applied to laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of inconvenient operation and lower work efficiency, and achieve the effect of convenient clamping and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

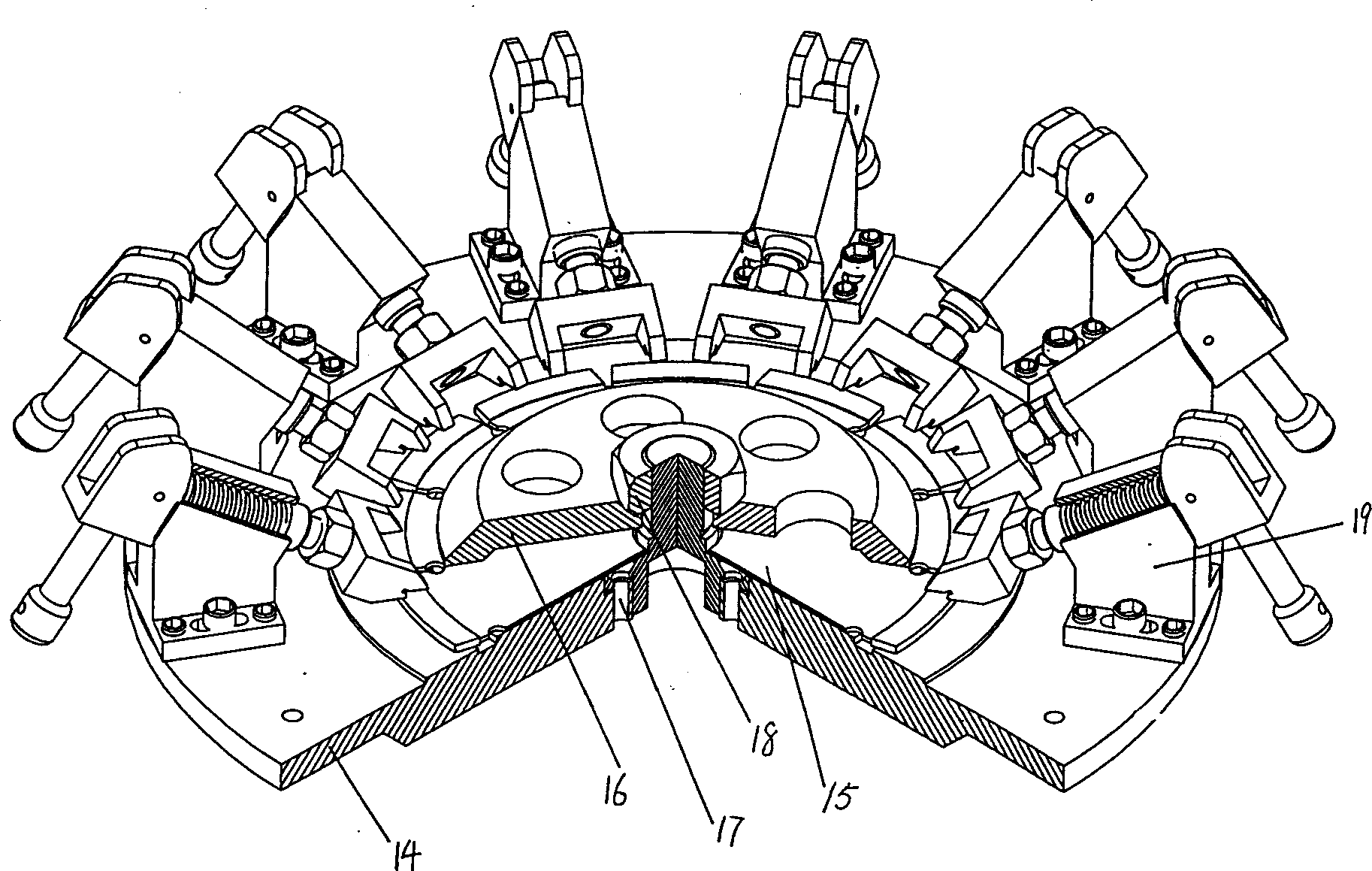

[0010] Such as figure 1 As shown, the chassis 14, the saw blade base 15, and the cover plate 16 are provided with a number of positioning holes 17, and in the center of them are provided with threaded central holes for fastening nuts 18, and several clamping devices 19 are installed on the chassis. 14 on.

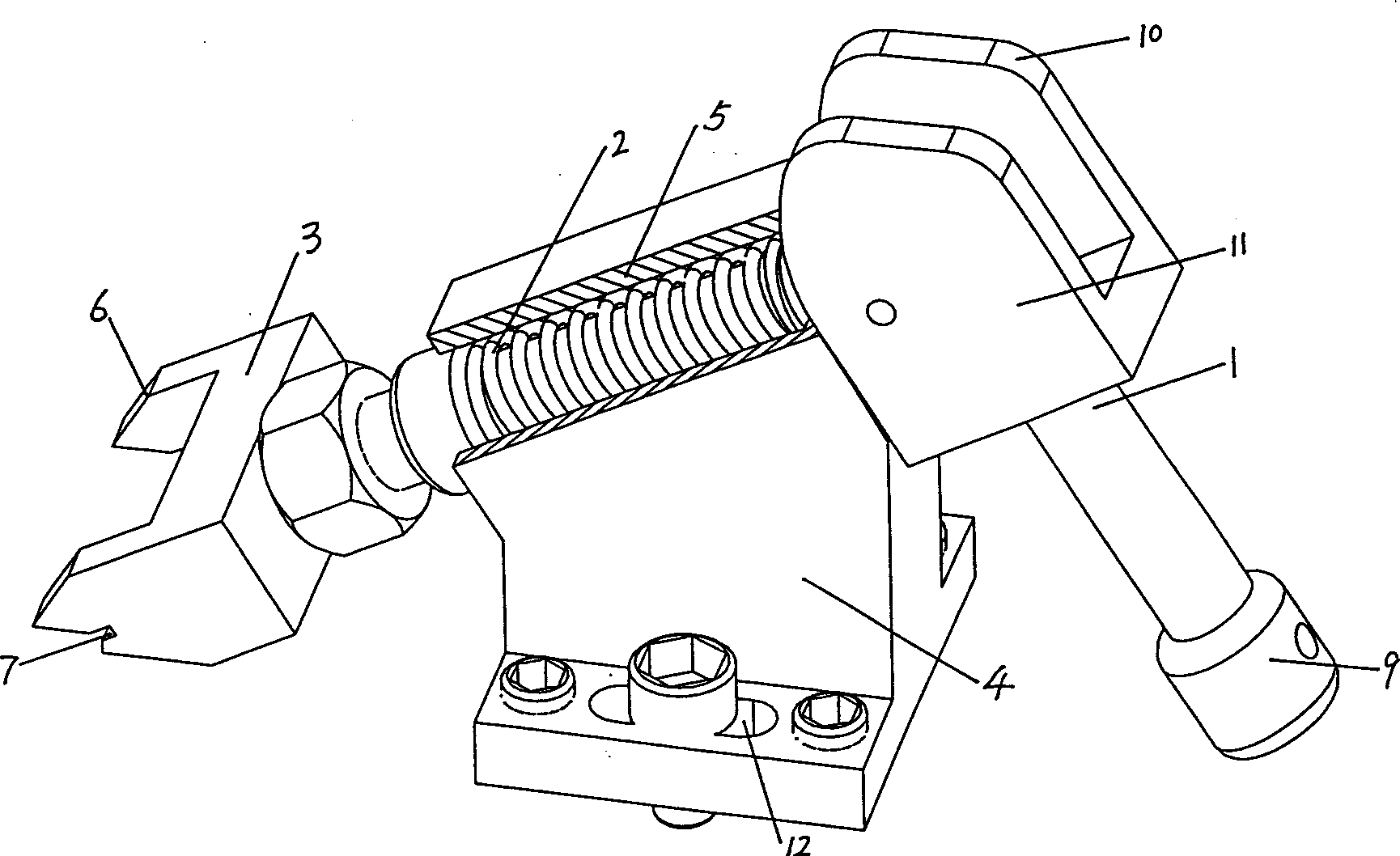

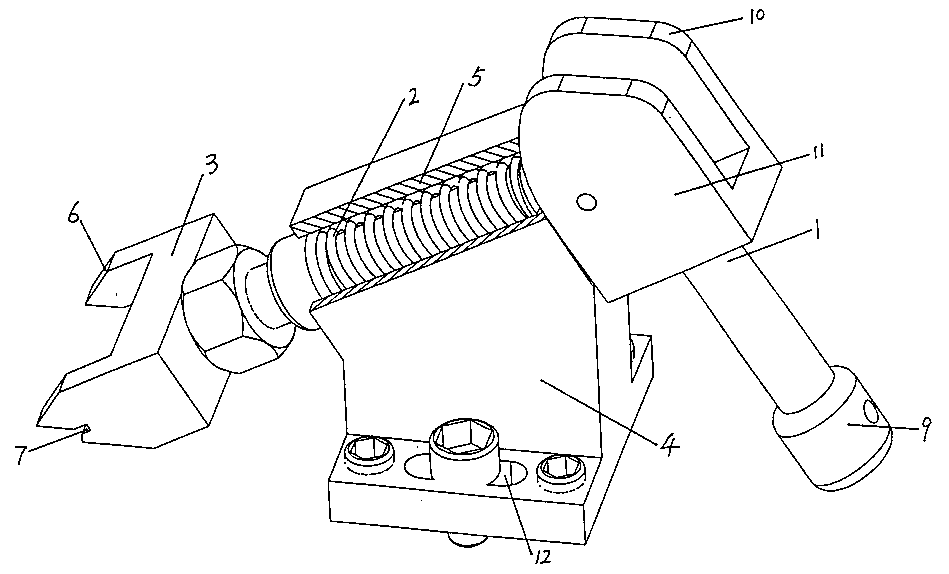

[0011] The structural representation of clamping device 19 is as figure 2 shown. The clamping device consists of an eccentric pull rod 1, a spring 2, a pressure head 3 and a base 4.

[0012] Indenter 3 is shape, The protruding portion 6 of the protruding portion is wedge-shaped, and the space left between the two protruding portions should be convenient for picking and placing the cutter head. The included angle θ between the wedge-shaped bottom edge of the protruding portion 6 and the upper surface of the indenter 3 should be Between 10-60°, and a groove 7 is opened at the bottom of the protruding part. The protruding part 6 and the groove 7 can clamp the cutter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com