Paper cutter with cutting knife moving vertically

A technology of vertical movement and paper cutting machine, which is applied to printing machines, rotary printing machines, printing, etc., and can solve the problems that it is impossible to make the best use of everything and it is difficult to meet the specification requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

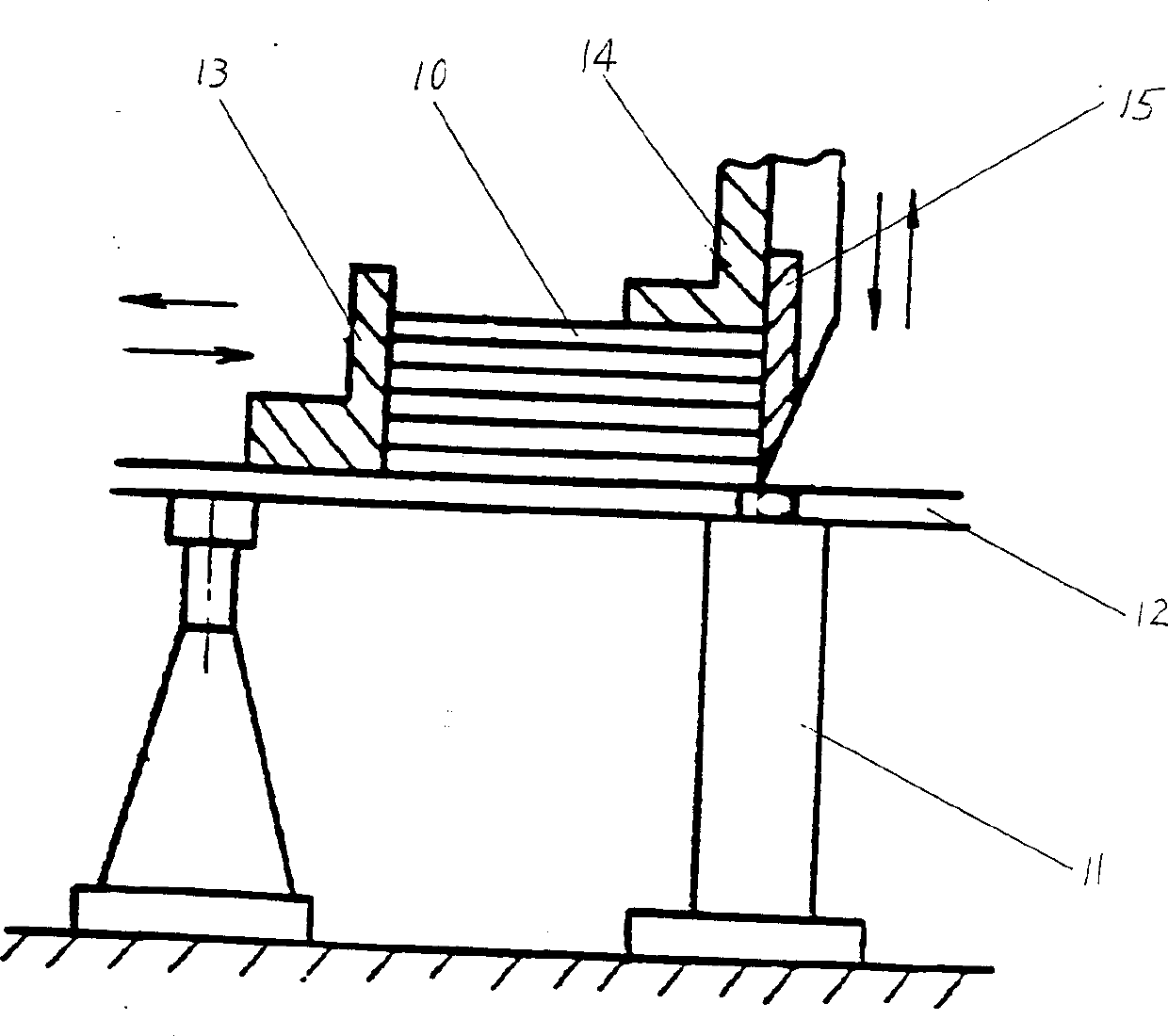

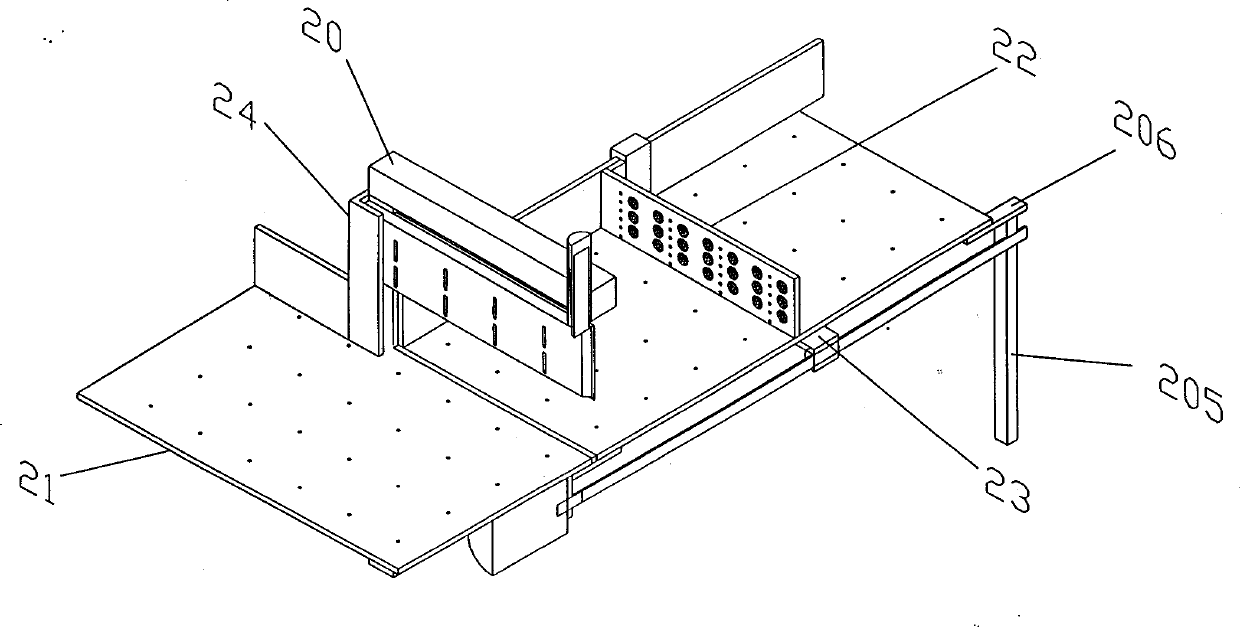

[0015] A kind of paper cutter embodiment that the blade moves vertically that the present invention designs is described in detail as follows in conjunction with accompanying drawing;

[0016] The overall structure of this embodiment is as figure 2 As shown in the figure, the structure of the left half sectioned along the longitudinal symmetrical axis of the paper cutter is shown in the figure, and the structure of the right half is completely symmetrical. This embodiment includes a frame 20, an air cushion workbench 21, a paper pusher 22 installed on the workbench, a motor and a screw drive mechanism 23, a knife bed system 24 and blades installed thereon. The above components are described in detail as follows:

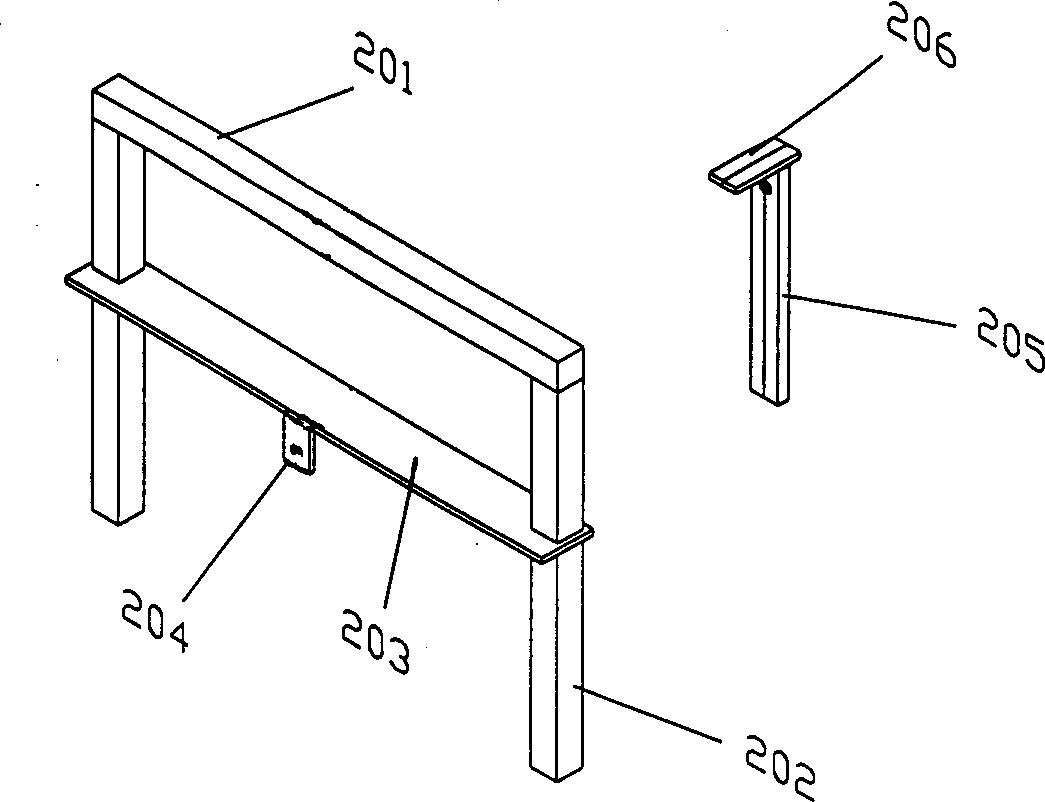

[0017] The rack structure of this embodiment is as image 3 As shown, it includes a frame composed of a top beam 201 and two columns 202 connected to its two ends, a front frame plate 203 installed on the two columns 202 and a motor support 204 installed on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com