Built-in hydraulic clamping chuck for spline cold rolling machine tool and assembly method

A hydraulic clamping and built-in technology, which is applied in the direction of guiding/positioning/alignment devices, etc., can solve the problems of poor axial positioning accuracy and achieve the effects of stable clamping force, precise axial positioning, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention can be explained in more detail through the following examples, and the purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

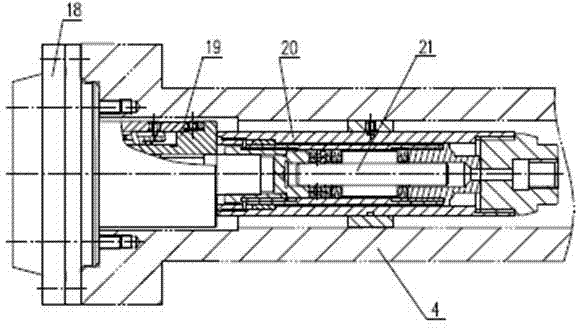

[0096] Depend on image 3 Known, the built-in hydraulic clamping chuck used for the spline cold rolling machine tool is installed on the end face of the machine tool spindle through the flange, and its rod is located in the hole of the machine tool spindle, including: flange positioning installation assembly 18, axial positioning Radial elastic clamping assembly 19 , connecting assembly 20 and elastic top assembly 21 . Among them, the flange positioning installation assembly 18 is located outside the left end of the built-in hydraulic clamping chuck for the spline cold rolling machine tool, and the axial positioning radial elastic clamping assembly 19 is located at the built-in hydraulic clamping chuck for the spline cold rolling machine tool. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com