Combined stack plate and its making method

A manufacturing method and a combined technology, applied in rigid containers, containers, packaging, etc., can solve the problems of non-disassembly into small pieces, dismantling and storage occupying space, poor applicability, etc., achieving obvious environmental protection effects, flexible and convenient assembly and disassembly. , Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

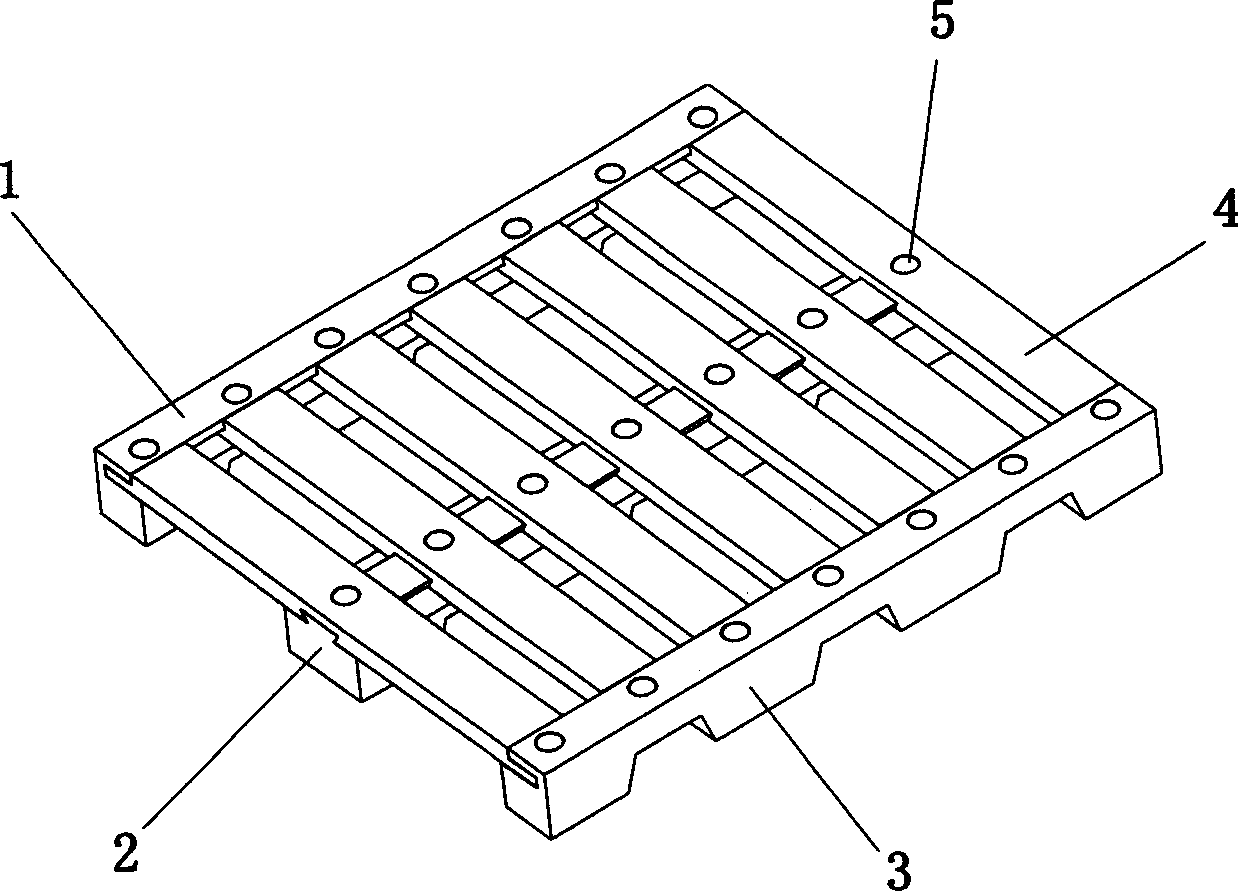

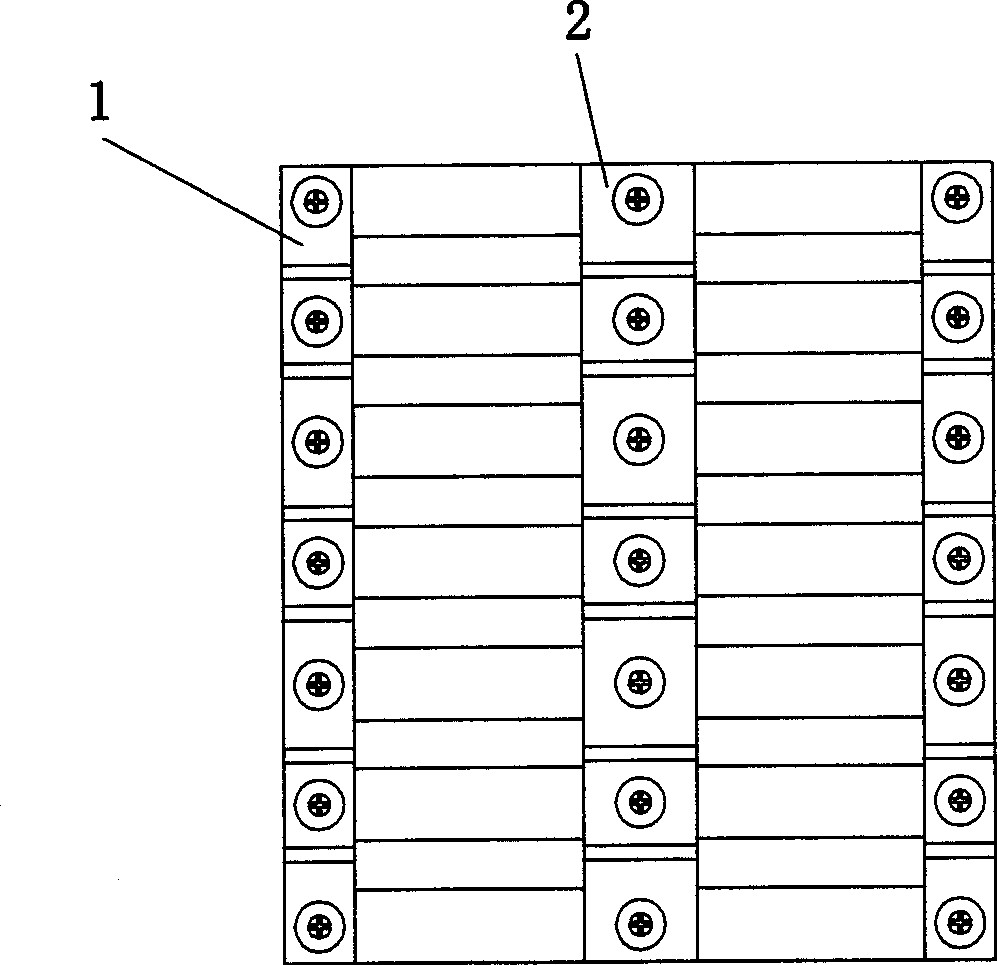

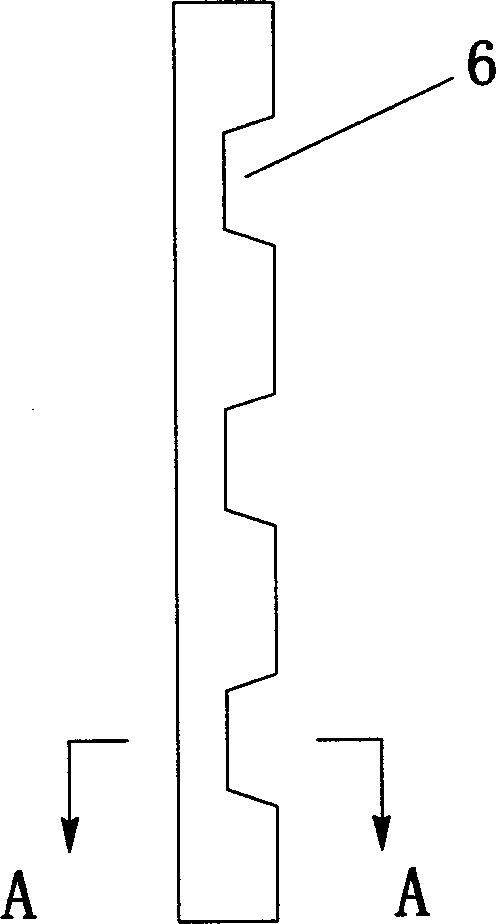

[0026] figure 1 shows the concrete structure of the present invention, by figure 1 It can be seen that the combined pallet is composed of two side support bars 1, 3, a middle support bar 2, seven load-bearing panel bars 4, and twenty-one fixing pins 5. The side support bars 1, 3 are located in the combined On both sides of the pallet, the load-bearing panel bar 4 is located in the middle of the combined pallet, and is connected to the middle support bar 2 and the side support bars 1, 3, and the fixing pin 5 is fixedly connected to the side support bars 1, 3, and the middle support bar 2 with the carrier panel strip 4; figure 2 Shows the shape of the bottom surface of the combined pallet after installation, image 3 Shows the side shape of the combined pallet, by figure 2 and image 3 It can be seen that the lower sides of the middle support bar 2 and the side support bars 1 and 3 of the combined pallet are processed with a shape that can be inserted by the force fork of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com