Process for extracting and refining tanshinone IIA by supercritical CO2

A carbon dioxide, supercritical technology, applied in the direction of organic chemistry, bulk chemical production, etc., to achieve the effect of simple process operation, not easy to degrade, and avoid the use of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

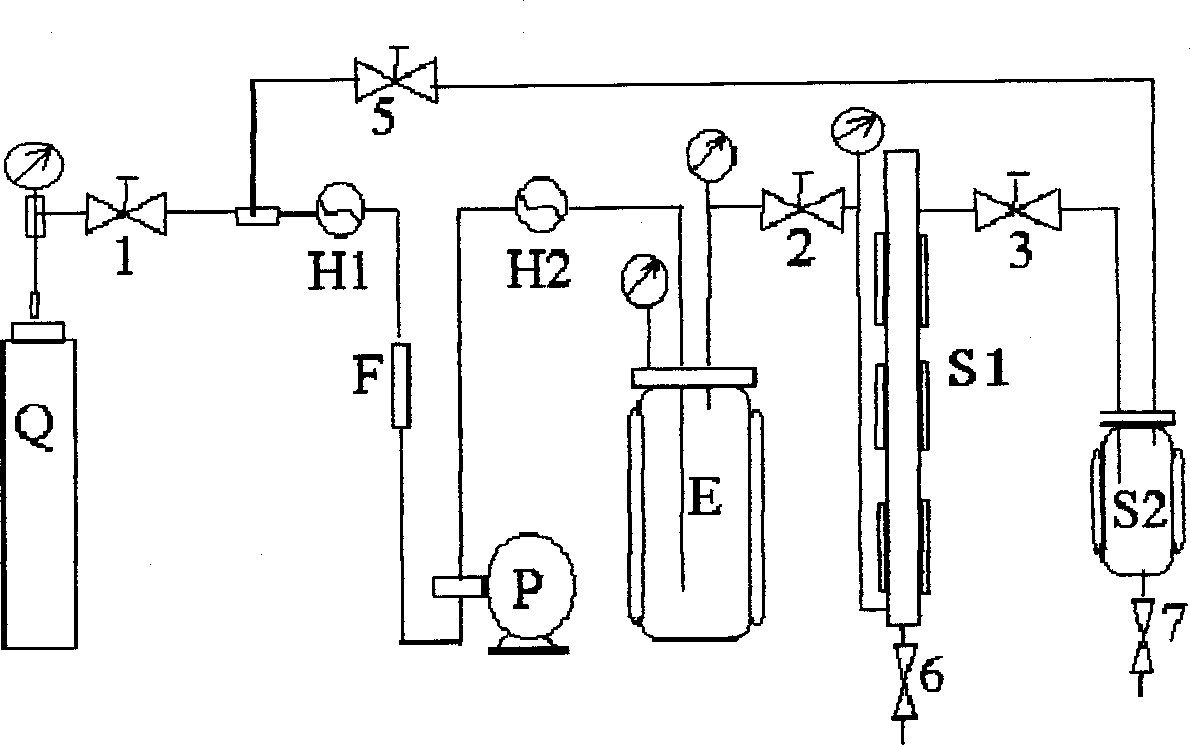

Image

Examples

Embodiment 1

[0015] Put 359g of commercially available traditional Chinese medicine salvia miltiorrhiza into the extraction kettle, keep the extraction pressure at 30MPa, and the extraction temperature at 40°C; the rectification column pressure at 7.5MPa, and the rectification temperature at 25°C, 3.59g of refined tanshinone IIA extract can be obtained; The pressure of the device is 6.5MPa, the separation temperature is 15°C, and 7.18g of fat-soluble extract and impurities can be obtained. The content of the active ingredient tanshinone IIA in the extract refined by the rectification column is 87%, and the yield of tanshinone IIA is 91%.

Embodiment 2

[0017] Put 582g of commercially available traditional Chinese medicine salvia miltiorrhiza in the extraction kettle, keep the extraction pressure at 40MPa, and the extraction temperature at 65°C; The pressure is 10MPa, the separation temperature is 55°C, and 13.4g of fat-soluble extract and impurities can be obtained. The content of active ingredient tanshinone IIA in the extract refined by rectification column is 89%, and the yield of tanshinone IIA is 98%.

Embodiment 3

[0019] Put 590g of commercially available traditional Chinese medicine salvia miltiorrhiza into the extraction kettle, keep the extraction pressure at 45MPa, and the extraction temperature at 75°C; the rectification column pressure at 32MPa, and the rectification temperature at 75°C, 1.8g of refined tanshinone IIA extract can be obtained; The pressure is 25MPa, the separation temperature is 75°C, and 11.6g of fat-soluble extract and impurities can be obtained. The content of active ingredient tanshinone IIA in the extract refined by rectification column is 95%, and the yield of tanshinone IIA is 37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com