Miniature silicon dridge type heat convection acceleration sensor

A technology of acceleration sensor and temperature sensor, which is applied in the field of sensors, can solve the problems of nonlinear output signal, large structure size, and low response frequency, and achieve the effect of small size, low cost, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

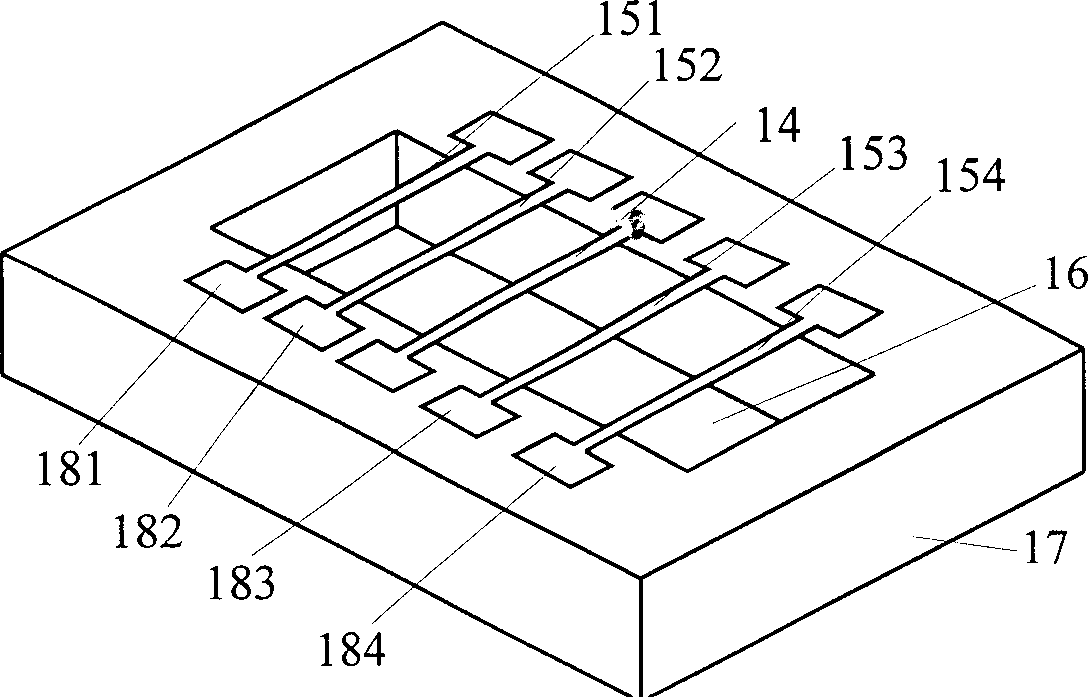

[0025] The embodiment of a miniature silicon bridge type thermal convection acceleration sensor designed in the present invention is described in detail as follows with reference to the accompanying drawings:

[0026] The structure of this embodiment is as image 3 As shown, it is mainly composed of a silicon base 17, a cavity 16 for providing natural convection space, a heating wire 14, a temperature sensor 151, 152, 153, 154 and their corresponding electrical contact pieces 181, 182, 183, and 184. The height of the silicon base 17 is 500 μm, the length of the cavity 16 is 3000 μm, the width is 910 μm, and the height is 250 μm. The heating wire 14 has a width of 80 μm and a height of 2 μm. The temperature sensor 15 has a width of 30 μm and a height of 2 μm. A pair of temperature sensors 152 and 153 close to the heating wire are symmetrically arranged on both sides of the heating wire, and their distance is 750 μm. Another pair of sensors 151 and 154 are also symmetrically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com