Electric flow control valve

A flow control valve, electric technology, applied in the direction of sliding valve, valve detail, multi-way valve, etc., can solve the problems of difficult flow control, adjustment of the degree of inability to open, and lack of freedom in flow control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

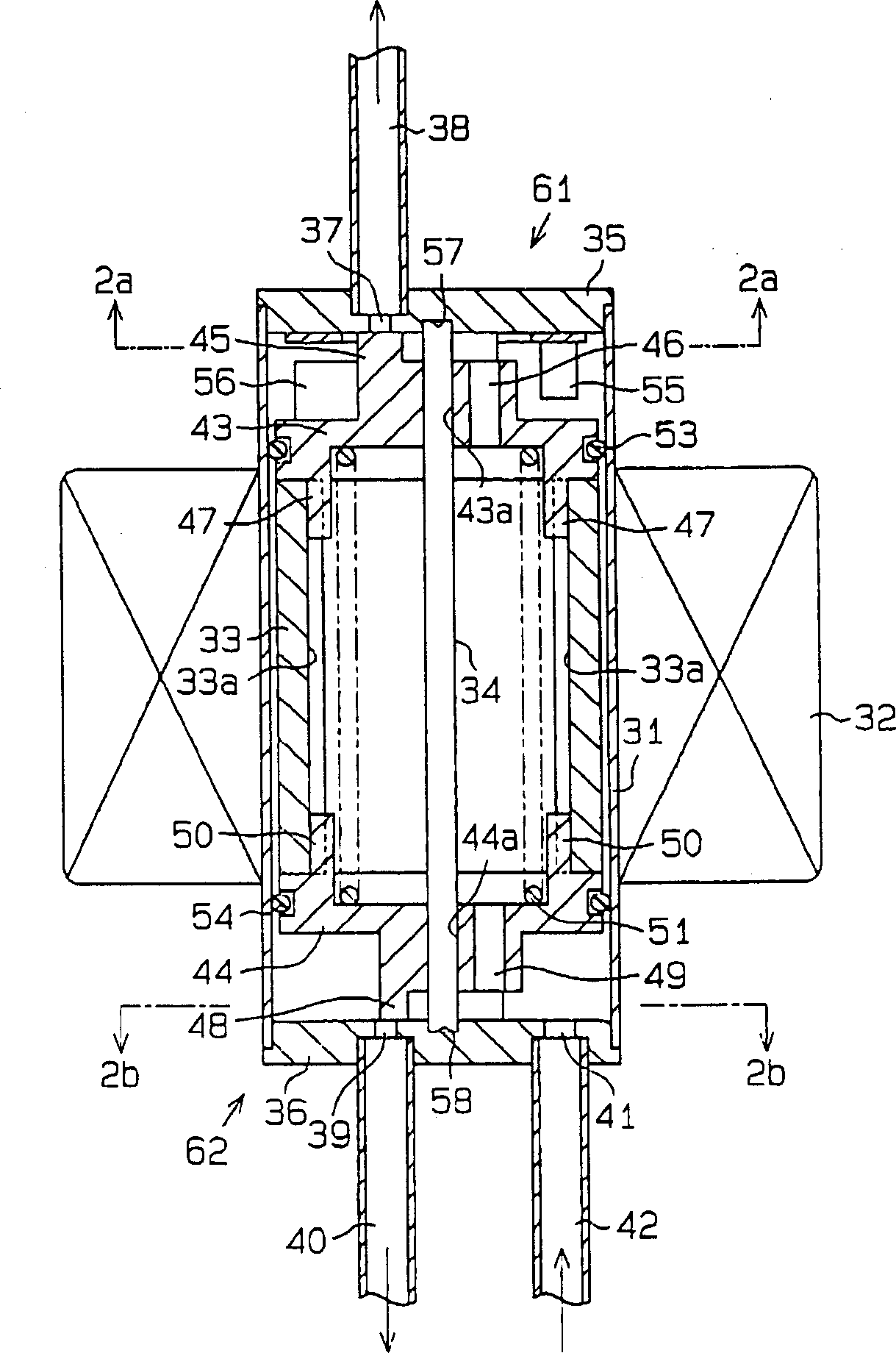

[0019] Refer below Figure 1~3 , an embodiment of the present invention is described. figure 1 The shown electric flow control valve is fitted, for example, in a coolant circuit of the heat pump type (not shown in the figure). The control valve comprises a cylindrical housing 31, the two ends of the cylindrical housing 31 are open, a first valve seat 35 and a second valve seat 36, and the first valve seat 35 and the second valve seat 36 are fixed to the valve seat in an airtight manner. The two ends of the cylindrical shell 31. The cylindrical case 31 is formed of non-magnetic metal. Around this cylindrical case 31, an electromagnetic coil 32 is installed. Electric current is supplied to the solenoid coil 32 through a controller (not shown in the figure).

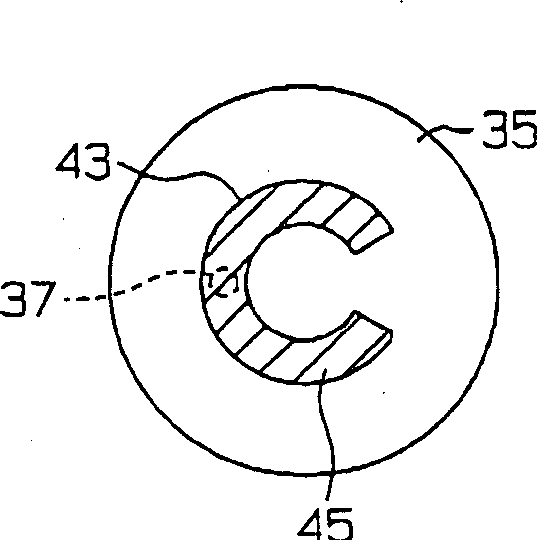

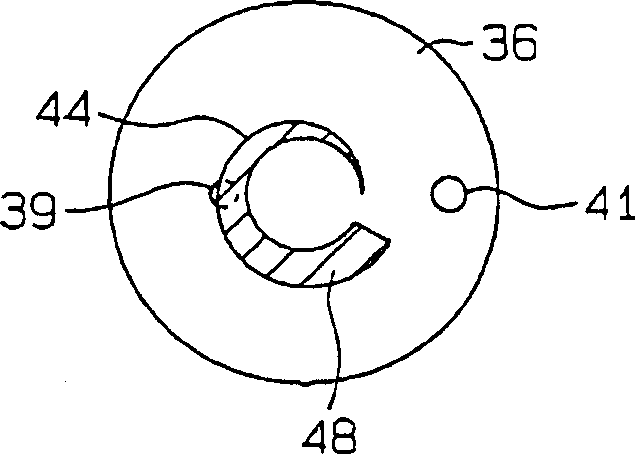

[0020] Each valve seat 35, 36 is disc-shaped. The first valve seat 35 has a first valve port 37 at a position away from the center, and the first valve port 37 communicates with the inner space of the cylindrical casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com