Drum-type washing machine

A drum type washing machine, drum technology, applied to other washing machines, washing machines with containers, washing machine control devices, etc., can solve the problems of large load, loud noise, vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

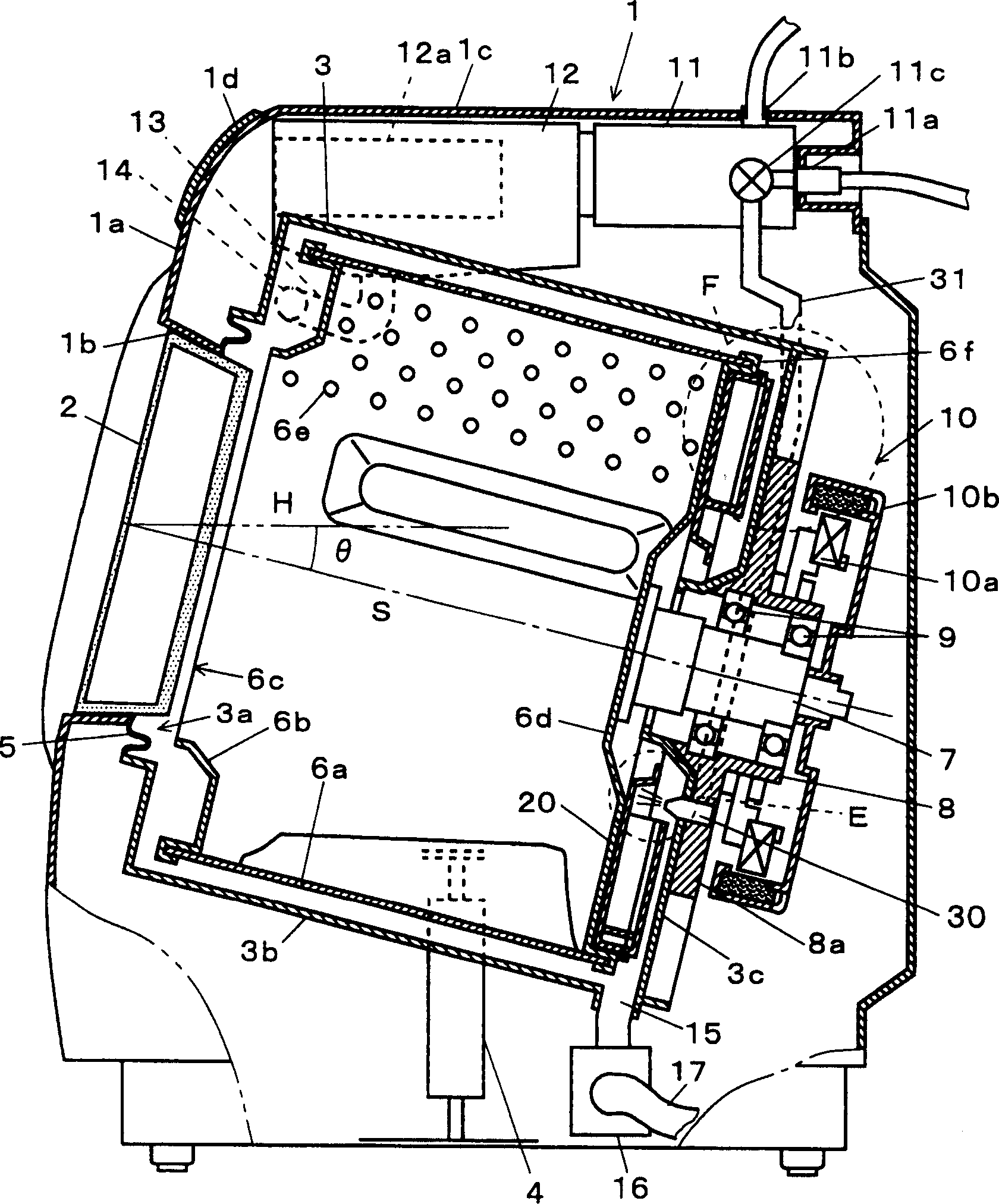

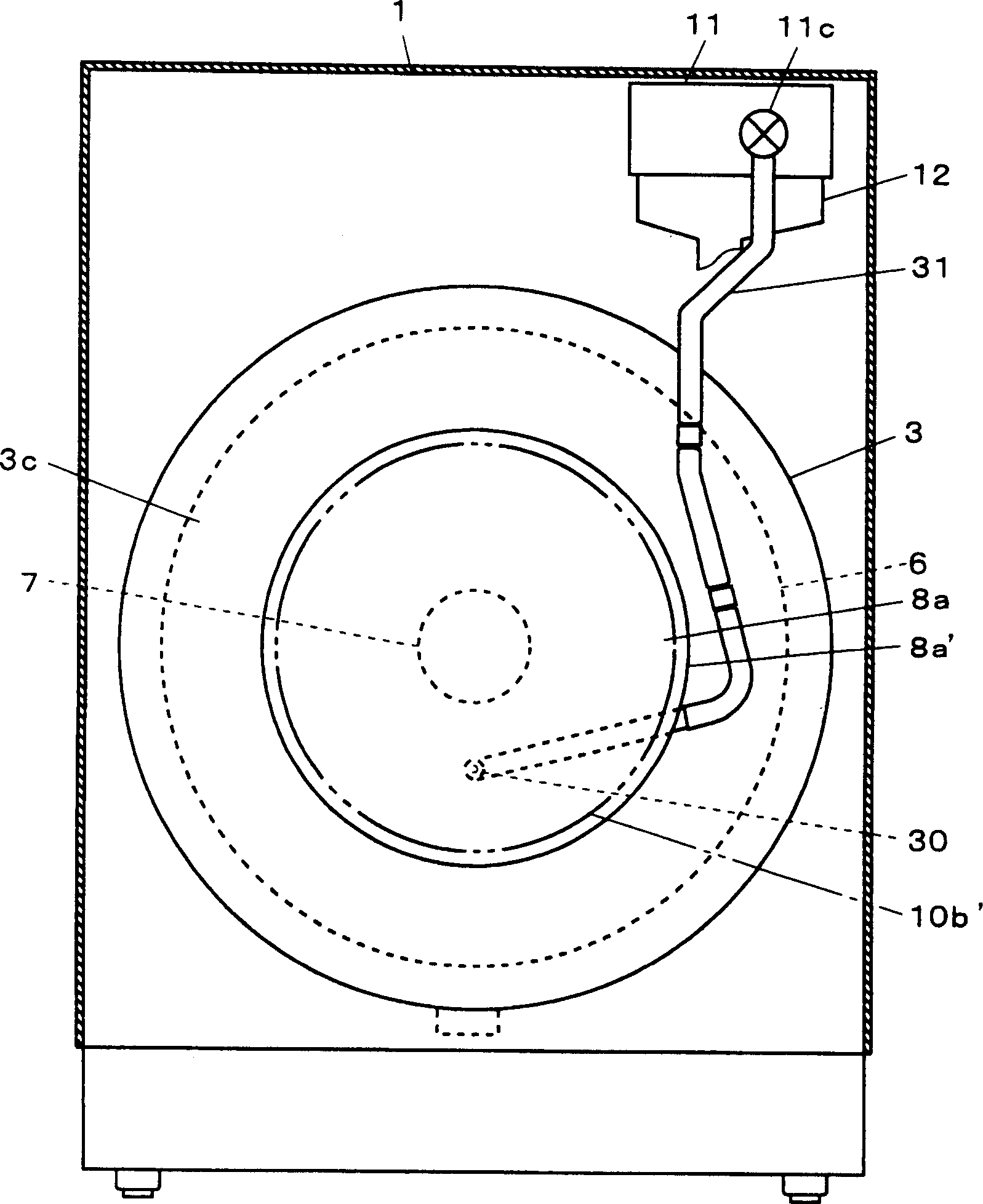

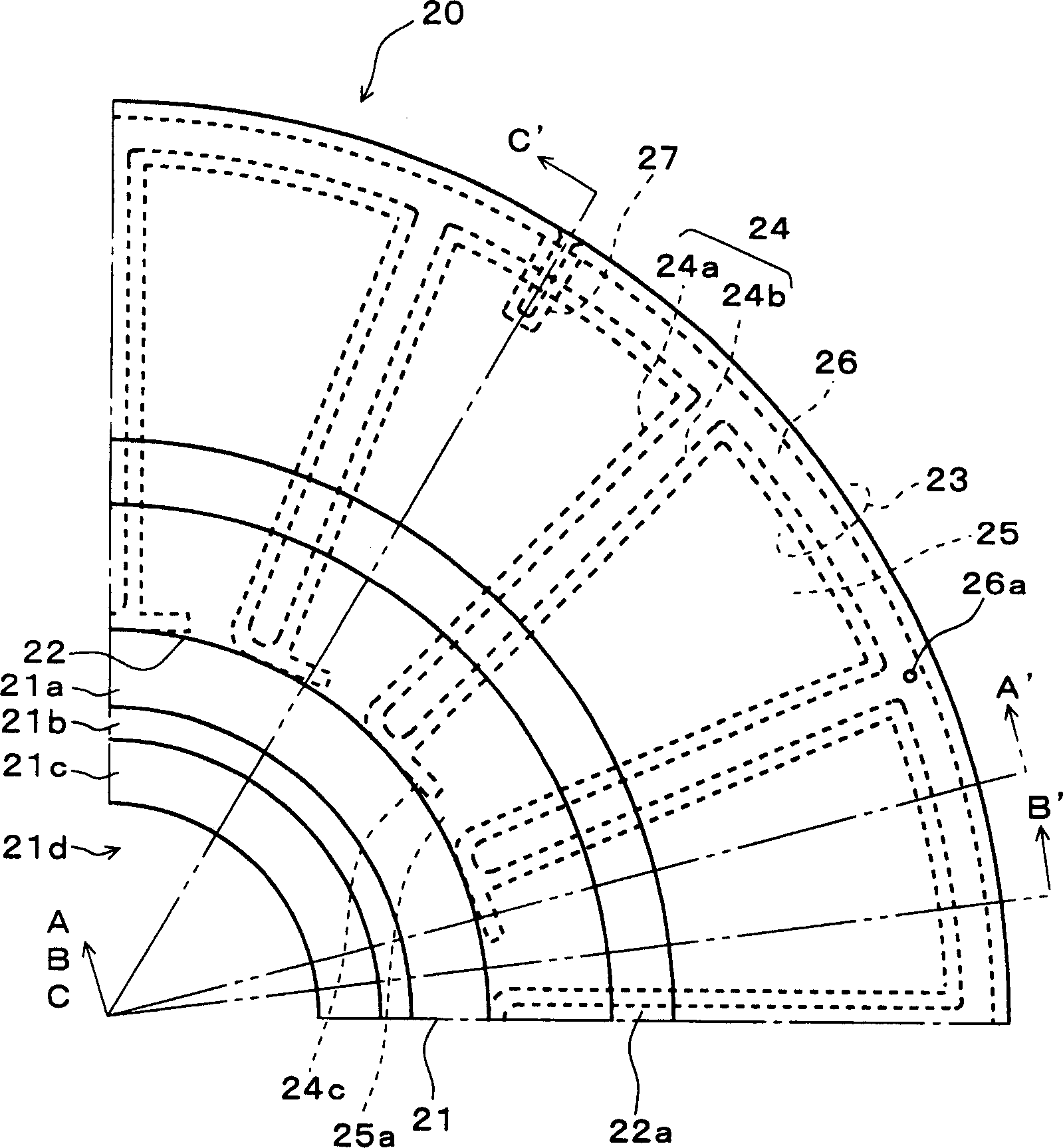

[0047] Hereinafter, a drum type washing machine according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a side longitudinal sectional view showing the overall internal structure of the drum-type washing machine of this embodiment, figure 2 It is the back perspective view of the main part.

[0048] The outer case 1 forming the outer shape of the front-loading washing machine has a front portion 1a facing obliquely upward, and a substantially circular clothes inlet 1b is formed on the front portion 1a, and a horizontal opening door 2 that can see through the inside is provided on the front portion 1a. The upper part of the front part 1a of the outer box 1 is curved backward while being continuous with the upper surface part 1c. On the curved part 1d, an unshown operation panel and a detergent container 12a that can be pulled out forward are provided.

[0049] The outer tank 3, which is located in the inside of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com