Squeeze-resisting safety seat of automobile

A car safety seat and anti-extrusion technology, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of front axle deformation, large seat size, and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

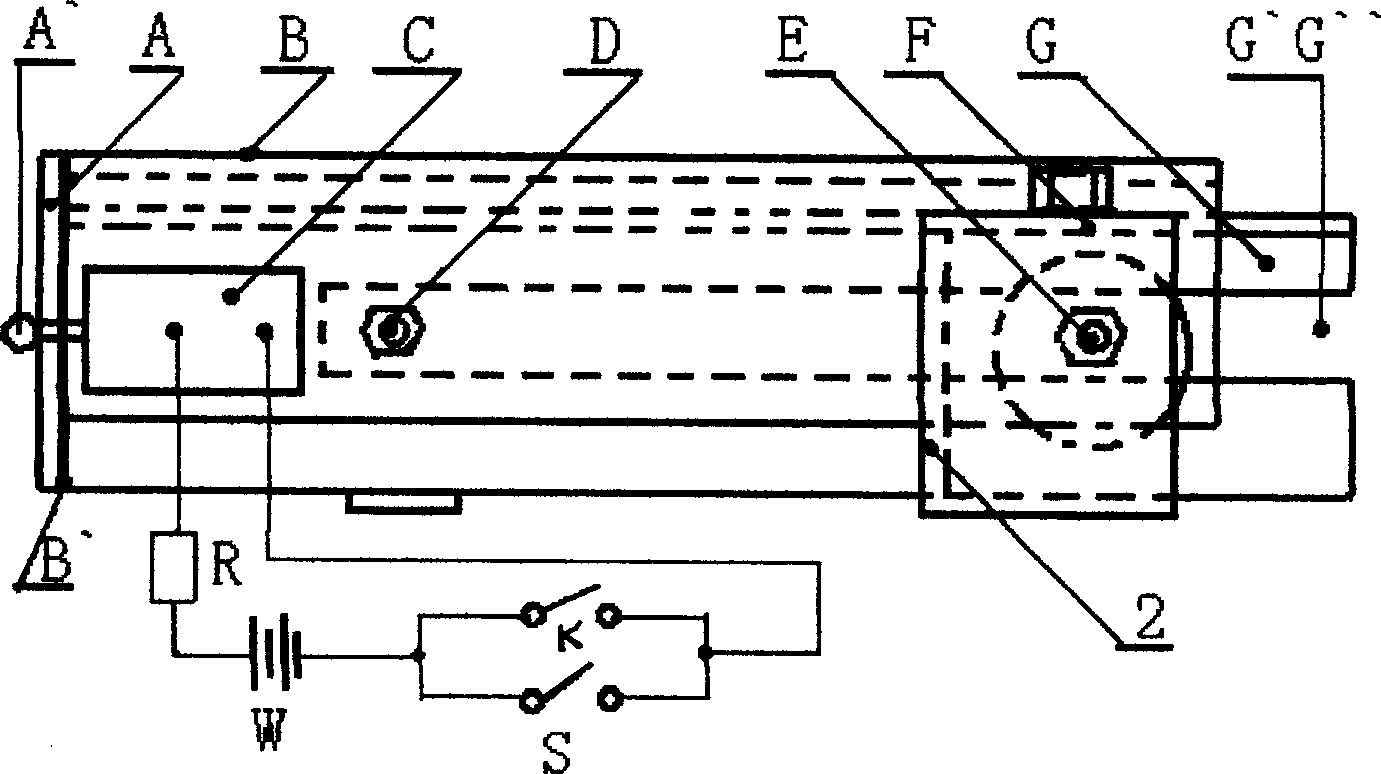

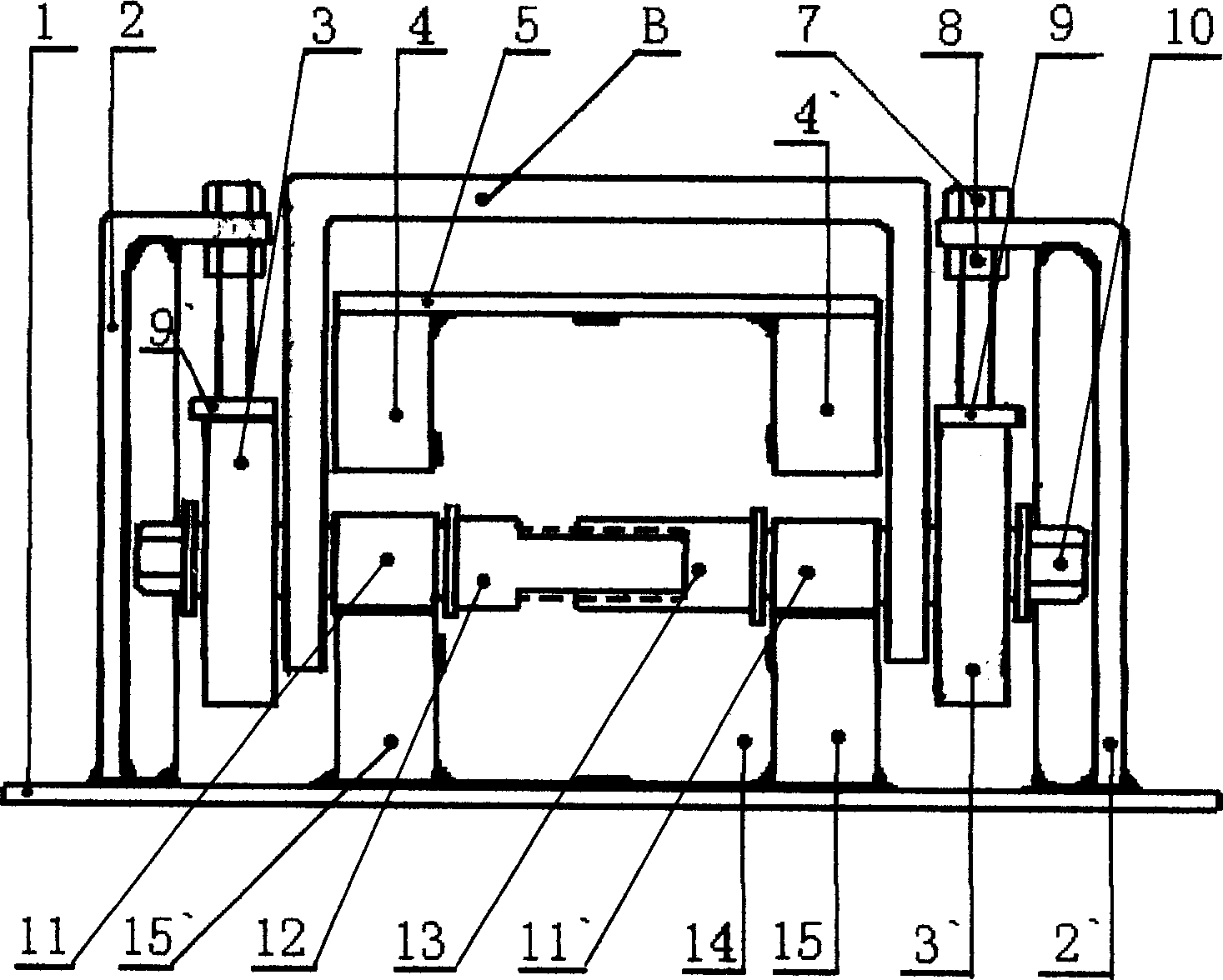

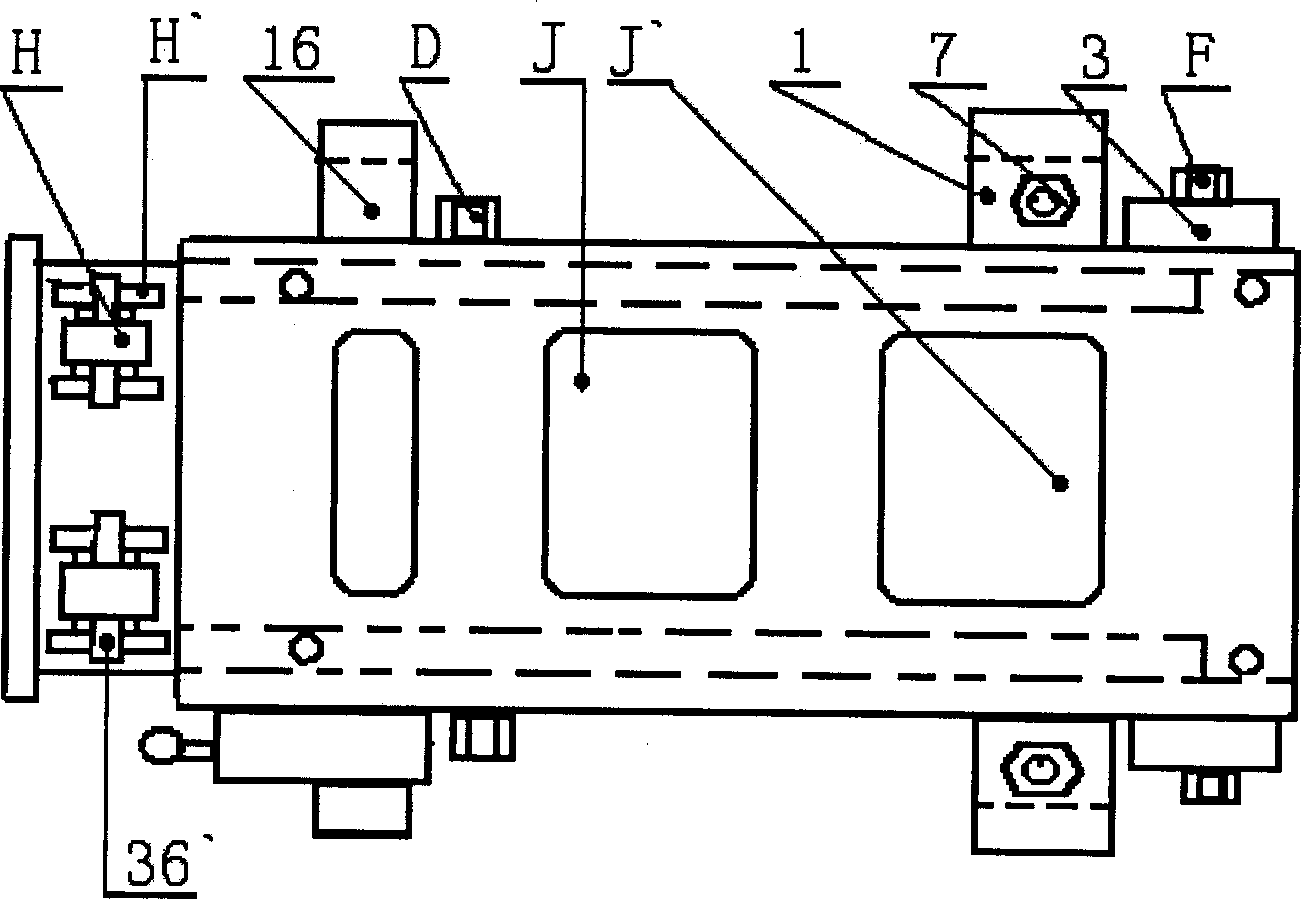

[0067] Normally, the large end of the lock bolt 27 extends from the round hole 17 on the movable frame B into the hole 20 on the fixed frame G, and then is sealed and locked by the metal block 23 integrated with the manual control hammer A` and the movable suction head 22. Up the seat. At this time, the front surface of the movable frame B is in contact with the buffer belt B`, and the lower surface is pressed on the energy-absorbing bearings H, H` on the energy-absorbing plate 5 of the fixed frame, and the bearings I, I` on the front axle D and the upper part of the track 4, 4'contact, the lock bolt 27 is in contact with the rear wall L of the hole 20. The rear part is: the rear axle inner bearings 11, 11` are supported by the lower part of the track 15, 15`, and the rear axle outer energy-absorbing bearings 3, 3` are pressed by the energy-absorbing nails 9, 9`. This ensures that the seat advances: the baffle A is blocked by the buffer belt B'. Backward: The rear wall with a hole...

Embodiment 2

[0075] The energy-absorbing bearings 57 and 58 on the outer side of the rear axle only have an energy-absorbing effect. The inner bearings 11, 11' that need to move backwards after an accident, so the outer diameter of the energy-absorbing bearings 57, 58 does not need to be larger than the inner bearing 11, 11` outer diameter, there must be a sealing plate 59 at the rear of the fixed frame. The rest is the same as in Example 1.

Embodiment 3

[0077] When a car accident occurs, the diagonal upward force at the rear of the movable frame is applied to the rear energy absorbing frames 60, 60 on both sides of the fixed frame through the energy absorbing plate 66 on the movable frame, the energy absorbing nails 62, 62 of the embodiment 3 Because the hardness of the movable frame B is much larger than that of the energy-absorbing plate 66, the energy-absorbing plate 66 is deformed, and similarly, it also absorbs part of the kinetic energy of the seat, so the rear axle outer energy-absorbing bearings 3, 3 are no longer needed. . Others are the same as Embodiment 2, but also protect the key components: front axle bearings I, I, rear axle bearings 11, 11', movable frame, track, front and rear axles. All have achieved the purpose of avoiding or reducing the squeezing of the driver and passenger and facilitating rescue of the injured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com