Charging rate regulator circuit of battery

A technology to adjust the circuit and charging rate, which is applied in the direction of secondary battery charging/discharging, battery circuit device, charge equalization circuit, etc., and can solve the problem that the battery module capacity becomes zero.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

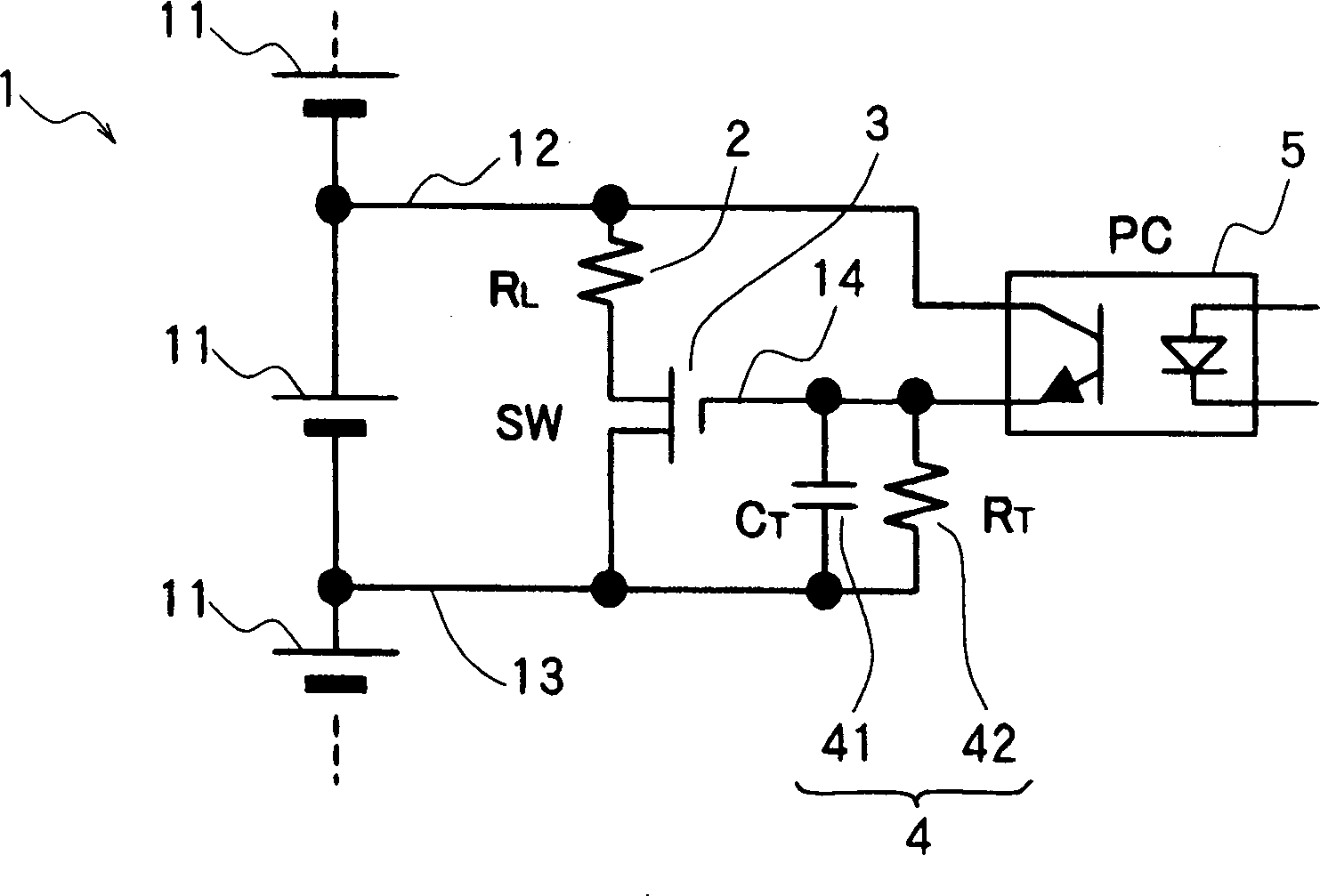

[0030] Such as figure 1 As shown, the charging rate adjustment circuit of the battery pack of this embodiment is aimed at the battery pack (1) formed by connecting battery modules (11) composed of a plurality of storage batteries in series, and according to the direction from the control system (not shown) A discharge command supplied from a specific battery module (11) discharges the battery module (11).

[0031] A pair of discharge lines (12) (13) are drawn from the two poles of each battery module (11), and a discharge resistor (2) with a relatively low resistance value and an on-off switch (3) composed of MOSFETs are interposed between the two discharge lines (12) ) (13), since the on-off switch (3) is closed, the current flows from the battery module (11) to the discharge resistor (2), constituting a discharge circuit for discharging the battery module (11). Connect the secondary side of the optocoupler (5) with a discharge line (12) and a control signal line (14) exten...

no. 2 Embodiment

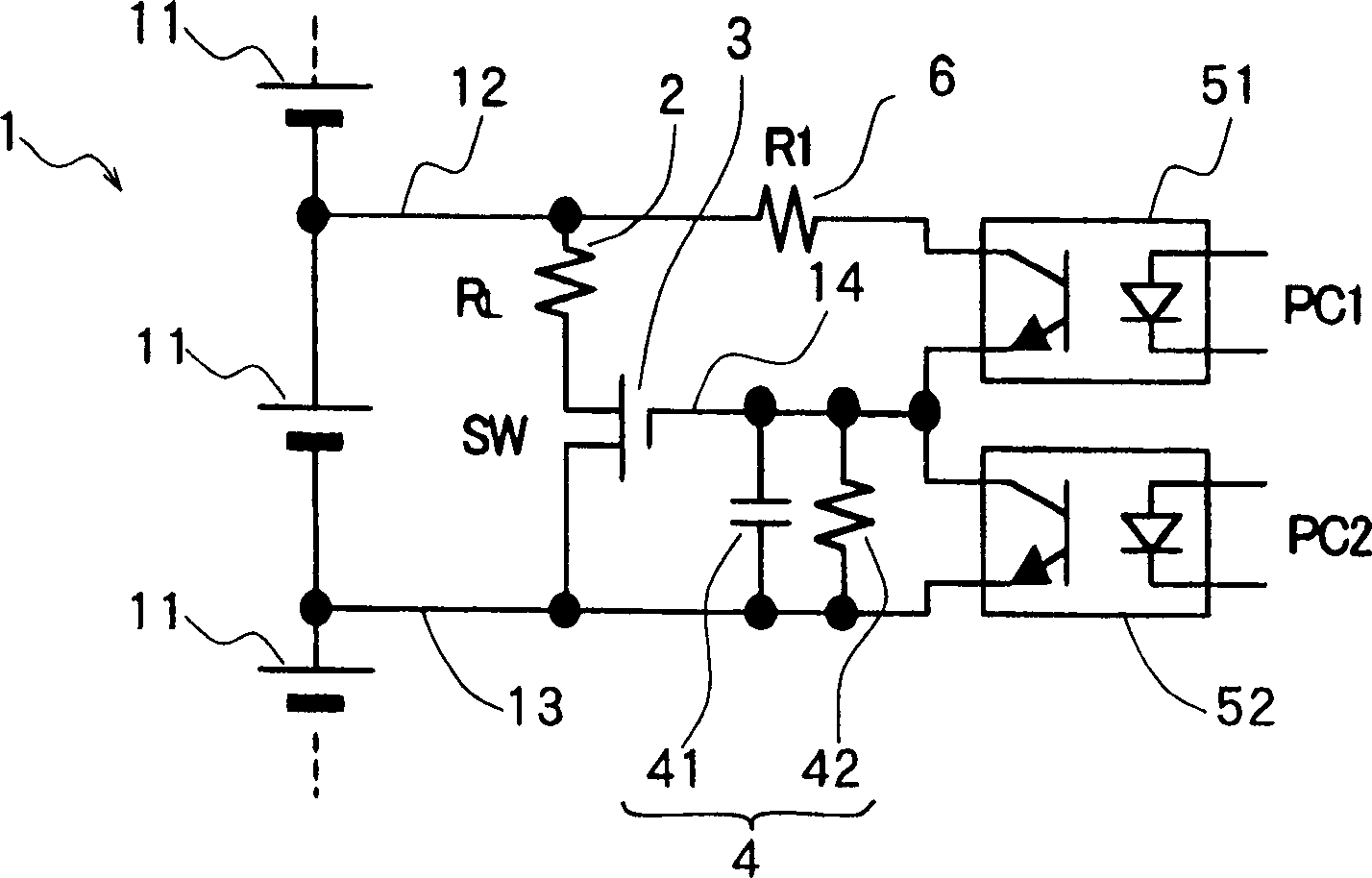

[0038] Such as figure 2 As shown, the charging rate adjustment circuit of the battery pack of this embodiment is a circuit that improves the charging rate adjustment circuit of the first embodiment, and the first optocoupler (51) for closing the on-off switch (3) is connected to the Between one discharge line (12) and the control signal line (14), at the same time connect the second optocoupler (52) for disconnecting the on-off switch (3) between the control signal line (14) and the other discharge line (14). Between lines (13). Furthermore, a short-circuit prevention resistor (6) is interposed on a discharge line (12).

[0039] According to this charging rate adjustment circuit, the on-off switch (3) can be closed according to the discharge command to the first optocoupler (51), so that the battery module (11) can start discharging, and at the same time, the discharge command to the second optocoupler can be The discharge stop instruction of (52) turns off the on-off switc...

no. 3 Embodiment

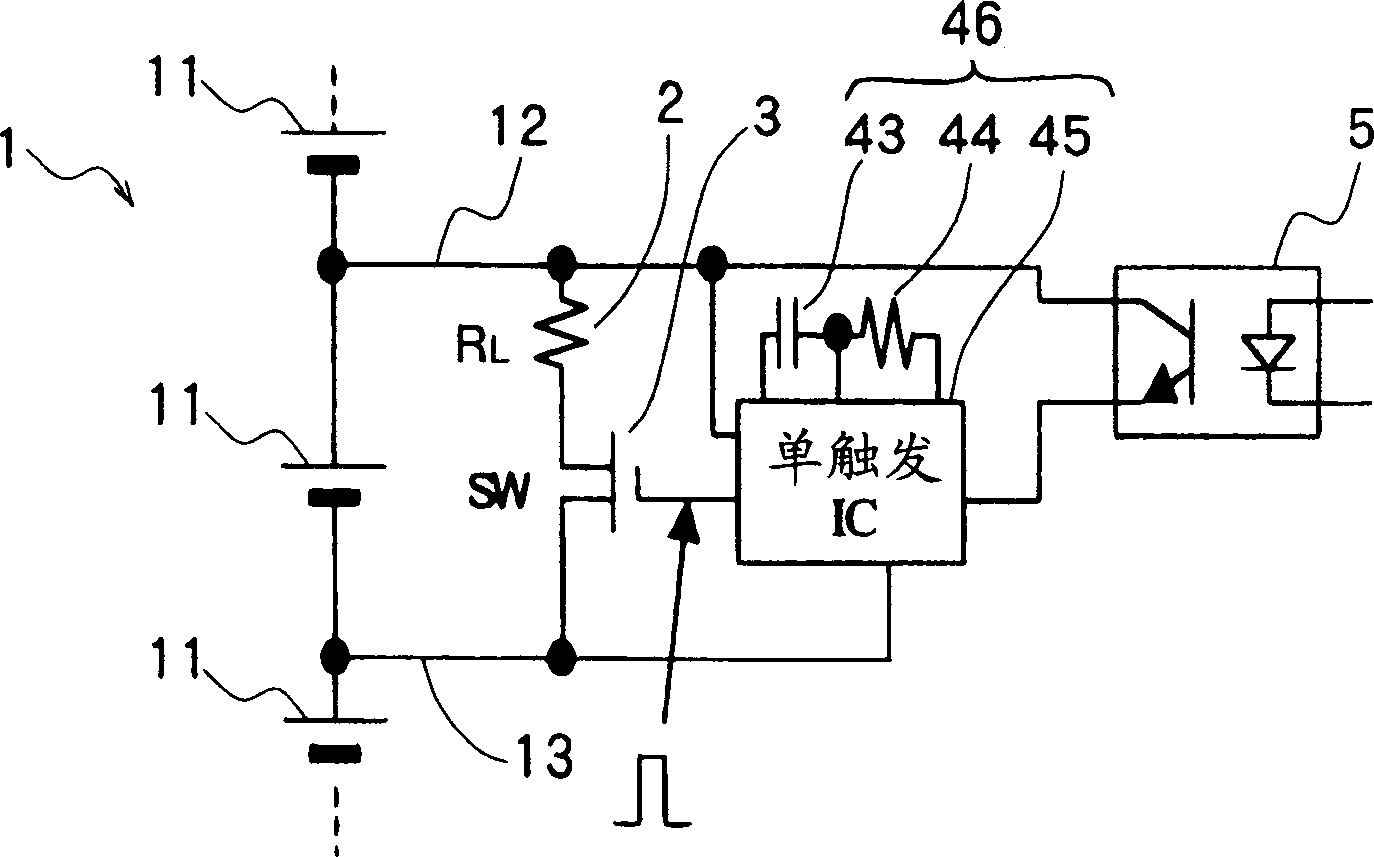

[0042] Such as image 3 As shown, the charging rate adjustment circuit of the battery pack of this embodiment is equipped with a time limit holding circuit (46) with a burst trigger IC (45) to replace the time limit holding circuit (4) composed of a CR circuit in the first embodiment. , capacitor (43) and resistance (44) are connected with impulse trigger IC (45).

[0043] When the discharge command ("high") is input from the control system (not shown) to the primary side of a specific optocoupler (5), the secondary side of the optocoupler (5) is turned on, and the time limit holding circuit The breath trigger IC (45) of (46) supplies the trigger signal, and the breath trigger IC (45) generates corresponding to the time constant determined by the capacitor (43) and resistance (44) accordingly, within a certain period of time is " High" control pulse and apply it to the gate of the on-off switch (3). Thus, the on-off switch (3) is closed within the above-mentioned certain tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com