Electrode assembly

A technology of electrode components and positive electrodes, which is applied in the field of electrode components on fire, can solve the problems of thermal stability reduction, thermal stability deterioration, and ignition, and achieve the effect of improving thermal stability and reducing charging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

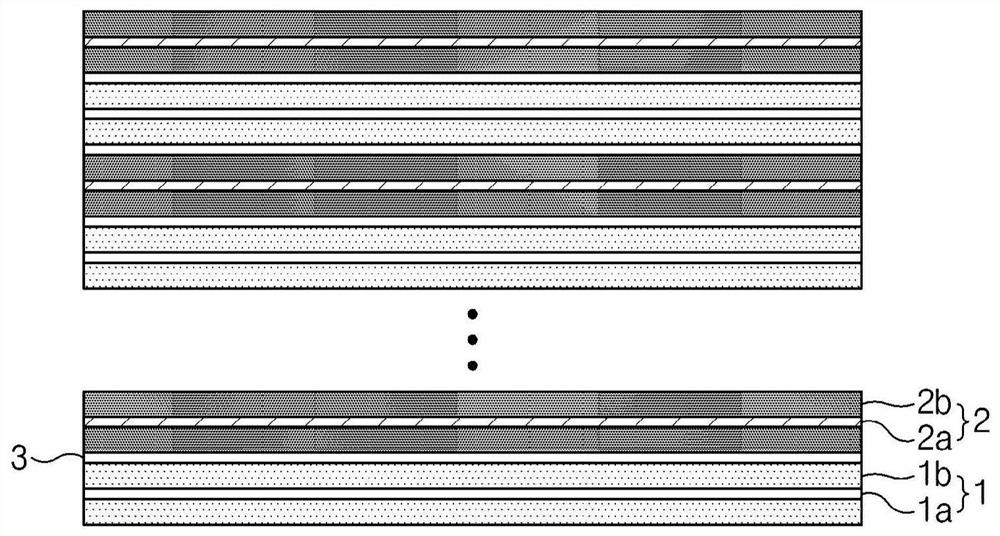

[0036] As described above, the electrode assembly according to the present invention includes the shrink film 31 that shrinks in area at a certain temperature or higher. In the present embodiment, a shrink film 31 is provided instead of the diaphragm 30 at each of the uppermost side and the lowermost side of the positions where the diaphragm 30 is provided.

[0037] Such as figure 2 as shown, figure 2 A side view is shown of an electrode assembly according to the present invention, in which a shrink film 31 is provided instead of the separator 30 at each of the uppermost side and the lowermost side of positions where the separator 30 is provided, the shrink film 31 Instead of the separator 30 being stacked at at least one or more positions between the positive electrode 10 and the negative electrode 20 , a shrink film 31 is provided at the stacked position of the separator disposed at the outermost side.

[0038]The shrink film 31 may be configured to separate the cathode ...

no. 2 approach

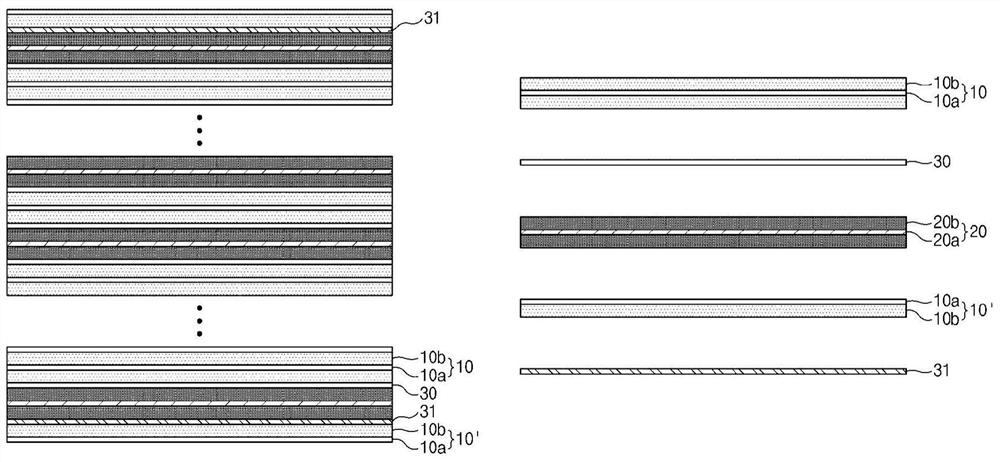

[0050] As described in the first embodiment of the present invention, the shrink film 31 may be stacked only at the position in contact with the single-sided positive electrode 10 ′, and may also be stacked on the positive electrode current collector 10 a in addition to the position in contact with the single-sided positive electrode 10 ′. One or more positions between the double-sided positive electrode 10 coated with positive electrode active material 10b on both surfaces of the negative electrode current collector 20 and the double-sided negative electrode 20 coated with negative electrode active material 20b on both surfaces of place. Alternatively, the shrink film 31 may be stacked only between the double-sided positive electrode 10 and the double-sided negative electrode 20, except for a position contacting the single-sided positive electrode 10'.

[0051] refer to Figure 4 , Figure 4 The state where the shrink film 31 is additionally stacked in addition to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com