Driver of pulse power supply for plasma aided chemical gas-phase deposition apparatus

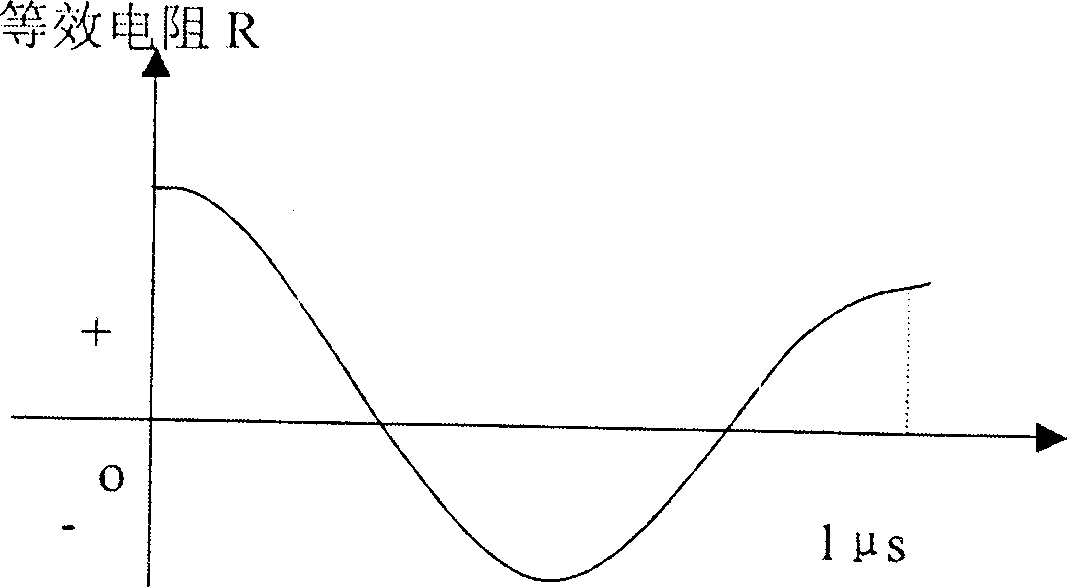

A chemical vapor deposition and driving circuit technology, which is applied in gaseous chemical plating, output power conversion devices, electrical components, etc., can solve the problems of not fully considering the complex characteristics of PCVD load, damage to high-power device IGBTs, etc. Impact capability, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] According to the technical scheme of the present invention, the drive circuit of the pulse power supply of the plasma-assisted chemical vapor deposition device includes four groups of mutually isolated drive circuits 40 arranged at the secondary output end of a high-frequency pulse transformer 41, and the drive circuit 40 is composed of: A resistor R1 and a capacitor C1 are connected in parallel. After the parallel connection, one end of the resistor R1 and capacitor C1 is connected to an output end of the secondary side of the high-frequency pulse transformer 41. On the output end, three connected Type diodes D1, D5 and D9; the negative poles of diode D5 are respectively connected to the positive poles of diodes D1 and D9; The cathode of the diode D5 in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com