Fuel oil pump

A technology of fuel pump and fuel oil, which is applied in the direction of pumps, pump devices, pump components, etc., which can solve the problems of increased time and cost, increased manufacturing cost of fuel pumps, etc., to reduce machining costs, ensure dimensional accuracy, and ensure accurate concentricity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

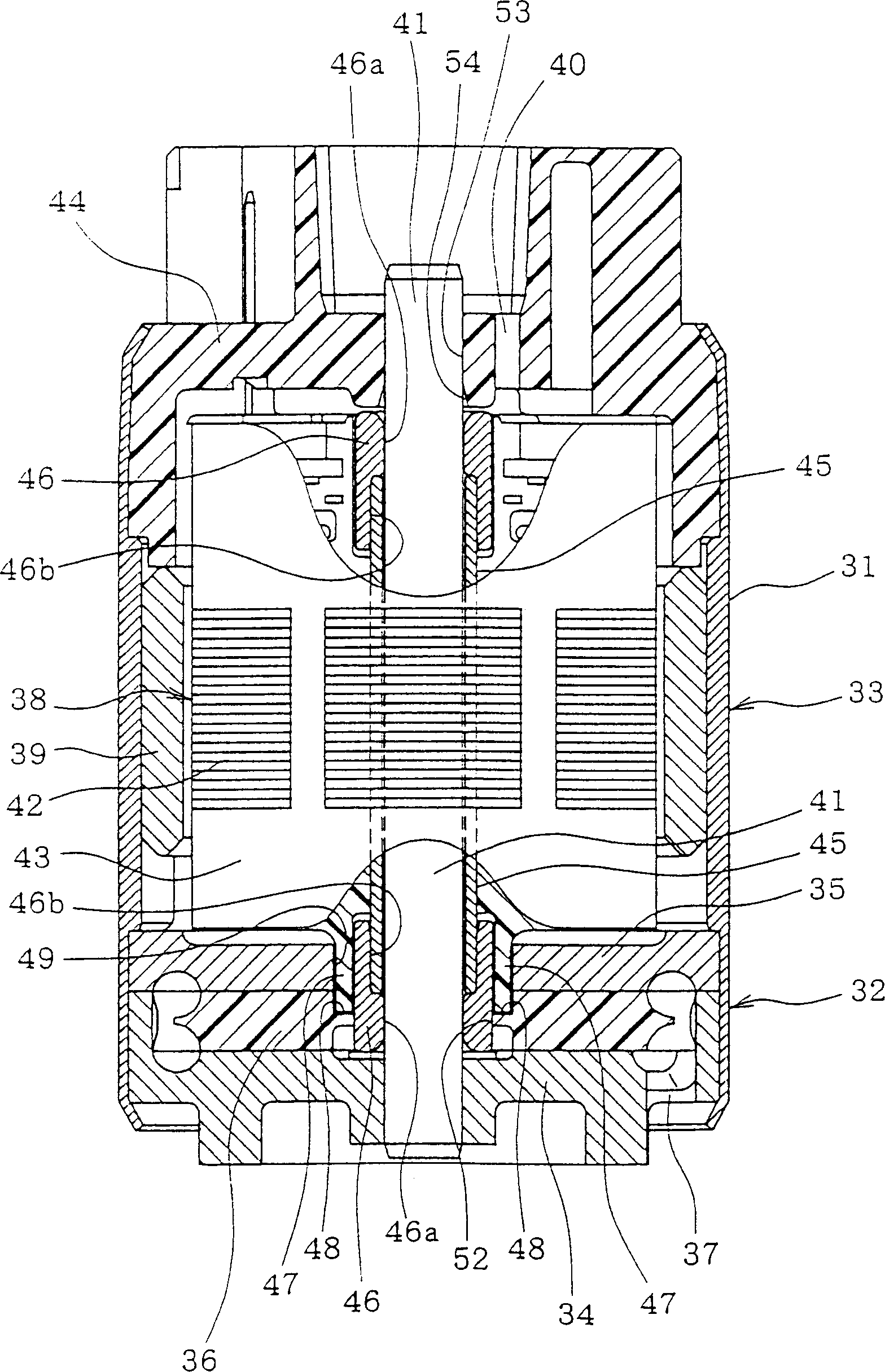

[0024] The following will be based on figure 1 and figure 2 The first embodiment of the present invention will be described. First, briefly explain the overall structure of the fuel pump. The pump unit 32 and the motor unit 33 are arranged in the axial direction, and are installed in the cylindrical housing 31 of the fuel pump. The pump unit 32 is constructed such that metal or resin pump casings 34 and 35 are fixed on the bottom end of the casing 31 by caulking or the like, and resin or metal impellers 36 (rotors) are stored in the pump casings 34 and 35 . A fuel suction (suction) port 37 is formed on the lower pump casing 34 . Fuel in a fuel container (not shown) is sucked into the pump housings 34 and 35 through a fuel suction port 37 . Fuel discharged from a discharge port (not shown) formed on the upper pump housing 35 is discharged from the fuel discharge port 40 after passing through a gap formed between the armature 38 and the magnet 39 of the motor unit 33 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com