Automatic high-efficiency energy-saving cooking vessel

A technology of cookware and automatic mode, applied in the direction of home utensils, kitchen utensils, cooking utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Before the disclosed embodiments of the invention are explained in detail, it is to be understood that the invention is not limited in application to the specific structural details shown, as the invention also has other embodiments. Also, the terminology used herein is for the purpose of description and not limitation.

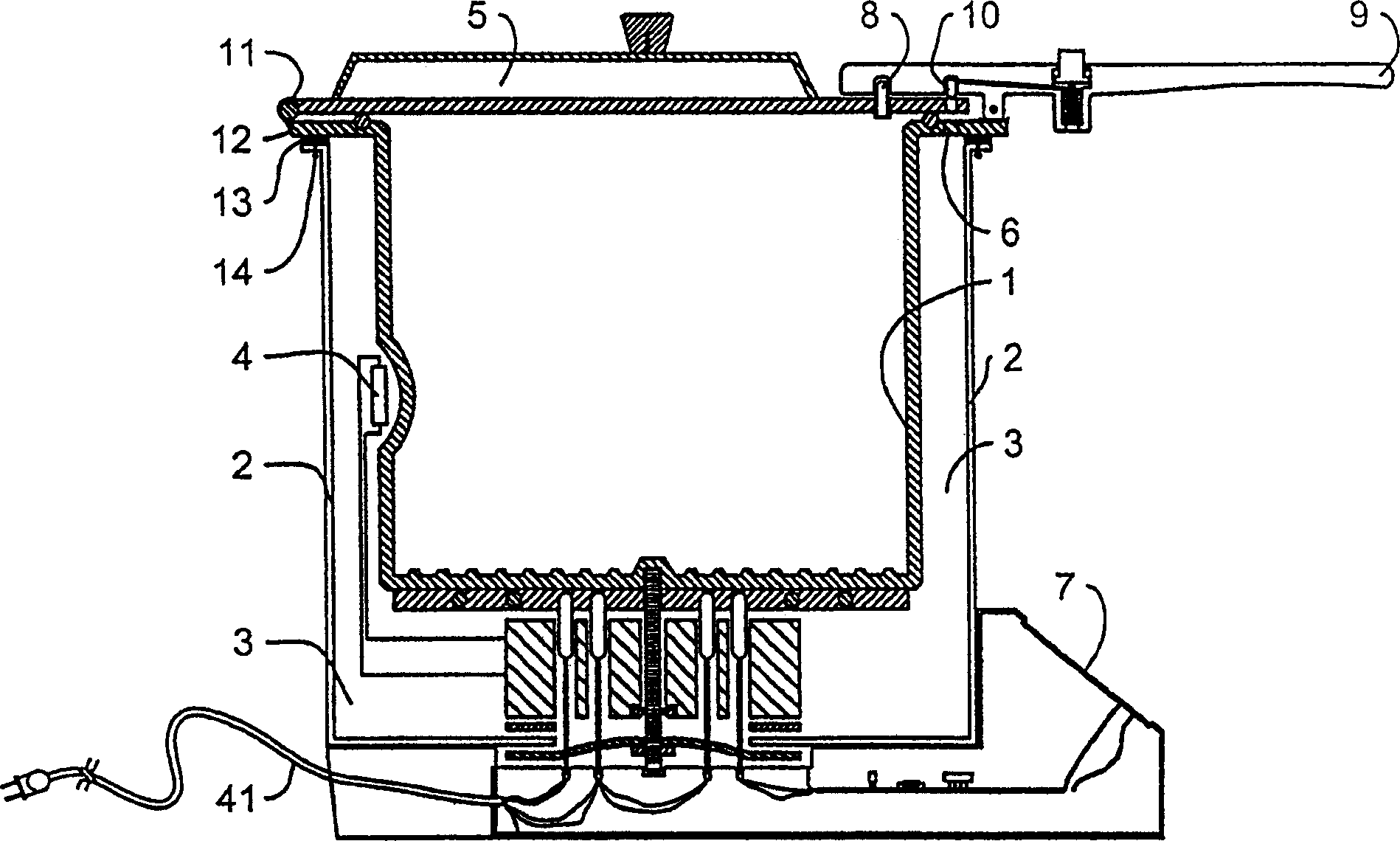

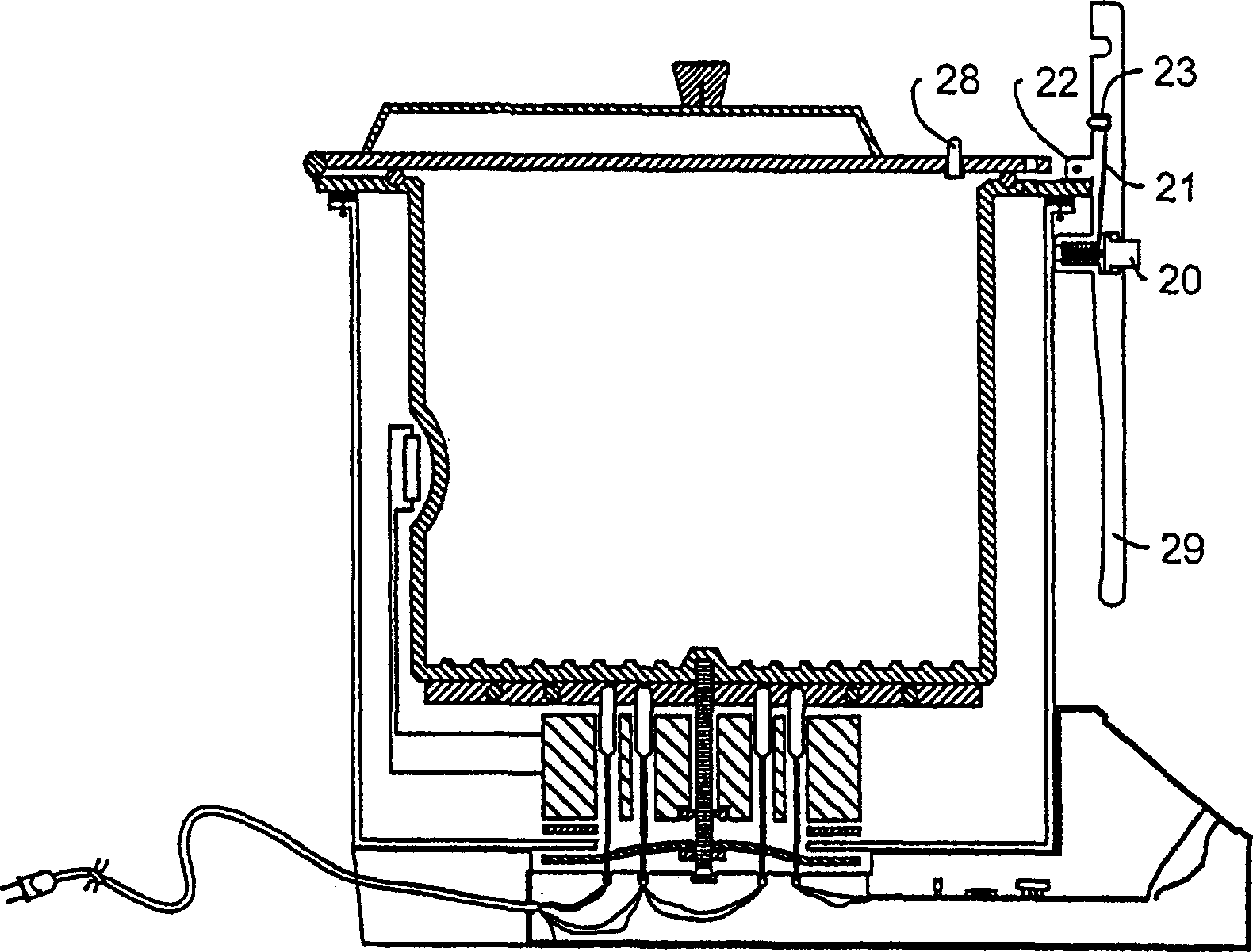

[0039]Generally, pressure cookers are designed to seal and control the steam that is generated when the water inside the cooker begins to boil. Thus, pressure cookers are constructed of strong and durable materials, such as stainless steel and heavy gauge aluminum, to safely withstand high pressures and temperatures. Pressure cookers also operate at temperatures within the pressure design limits and within their heating and cooling capabilities to affect the characteristics of the food. For example, the design pressure limit is generally one or half an atmospheric pressure unit above ambient pressure. Atmospheric or ambient pressure is 14.7 pounds pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com