Vacuum electric heat-insulation vessel and vacuum welding process

An electric heating and vacuum technology, applied in welding equipment, manufacturing tools, appliances for boiling water, etc., can solve the problems of poor thermal insulation effect, damaged electric heating elements, no heating function, etc., to achieve reliable sealing performance, convenient maintenance and replacement, and improved heating The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

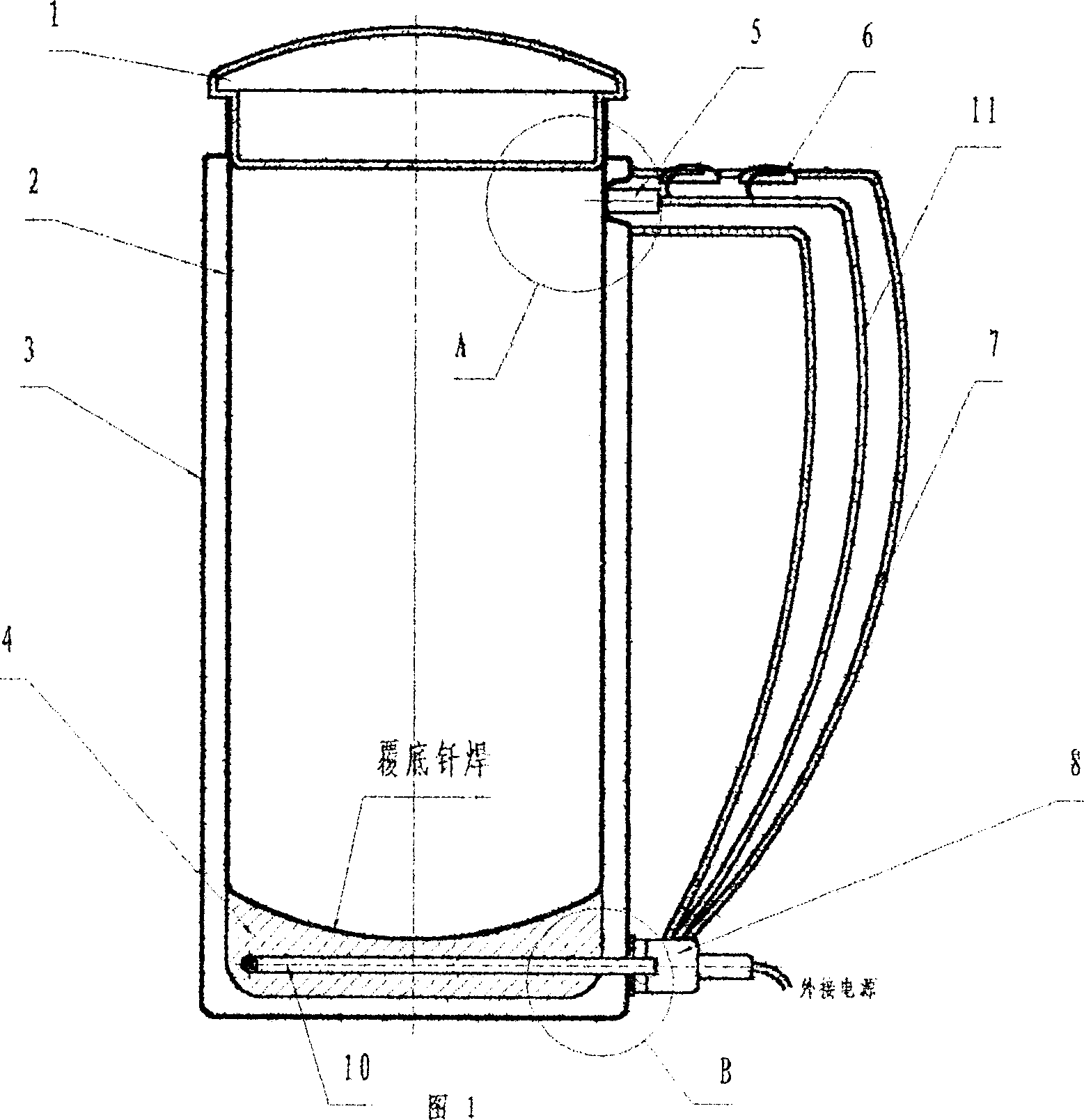

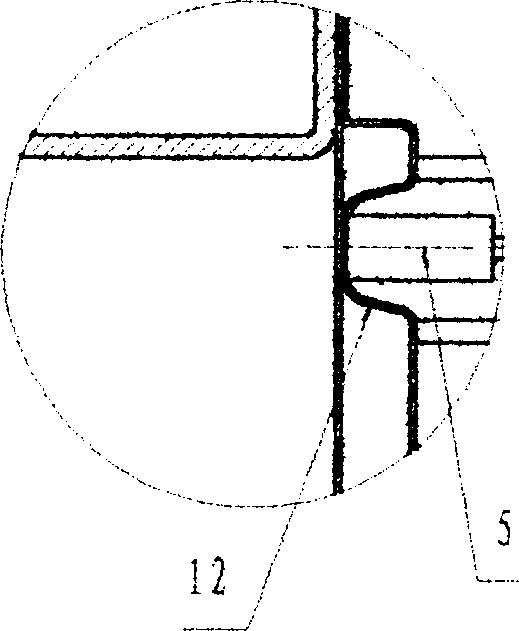

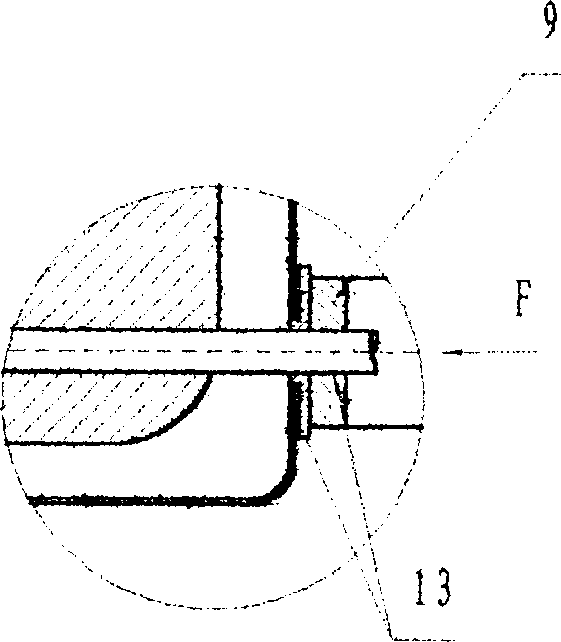

[0015] In this embodiment, the stainless steel vacuum electric thermos cup is taken as an example, see Fig. 1 to Figure 4 . This embodiment is mainly composed of a stainless steel inner tank 2, a stainless steel outer tank 3, a bottle cap 1, an electric heating element, a temperature controller 8 and a temperature sensor 5, wherein the temperature signal detected by the temperature sensor 5 is transmitted to the temperature controller through the signal line 11 The temperature controller 8 and the temperature controller 8 control the working condition of the electric heating element according to the above-mentioned temperature signal. 3 is provided with dimple 12, and the bottom of this dimple 12 is in contact with liner 2, and its contact position is connected by spot welding to ensure reliable contact. The temperature sensor 5 is a bimetal, which is placed in the pit 12 for detecting the water temperature in the inner tank 2 .

[0016] The electric heating element adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com