Heat-sensitive Mn-Zn ferrite series material combined synthesis and high throughput screening method

A heat-sensitive manganese-zinc and screening method technology, which is applied in the direction of inorganic material magnetism, can solve the problems that the series of bulk heat-sensitive ferrite magnetic materials have not been reported at home and abroad, and achieve low cost, high efficiency and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

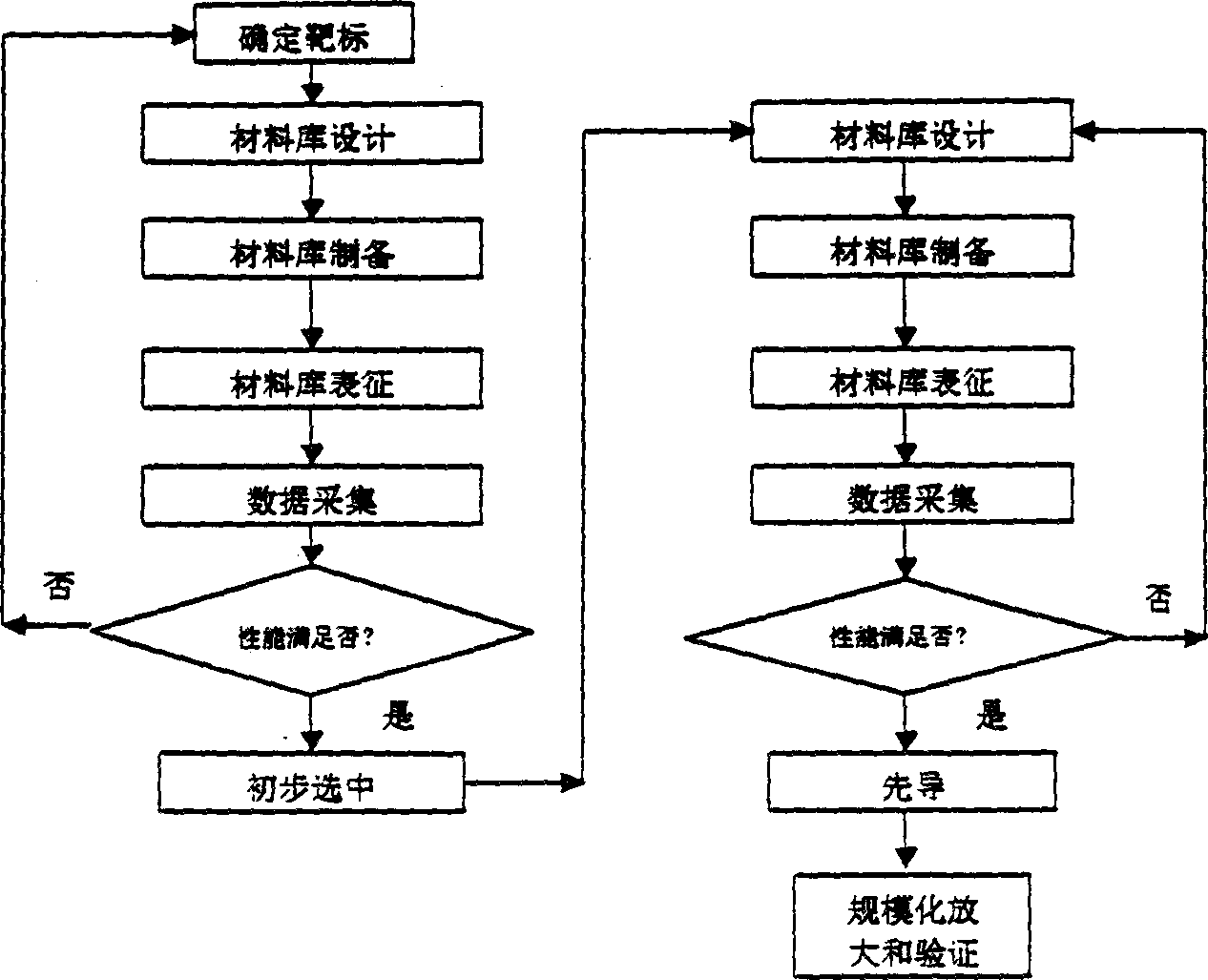

[0037] In the embodiment of the present invention, according to figure 1The process shown, using combined synthesis and high-throughput screening technology, carried out specific development and screening of heat-sensitive manganese-zinc ferrite series materials, and completed and established a temperature range of -40°C-+160°C in less than half a year. For the material library within the range, the Curie temperature interval is 2°C, the material permeability μ>2000, the maximum slope of the μ-T curve is greater than 145 / °C, and the μ-T characteristics are excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com