Driving cutting device

A cutting shaft and power technology, applied in cutting machinery, mining equipment, earth-moving drilling, etc., can solve the problems of slow driving speed, increased difficulty in subsequent roadways, and high operating costs, and achieve structural stability and high driving efficiency. ,Easy to use and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

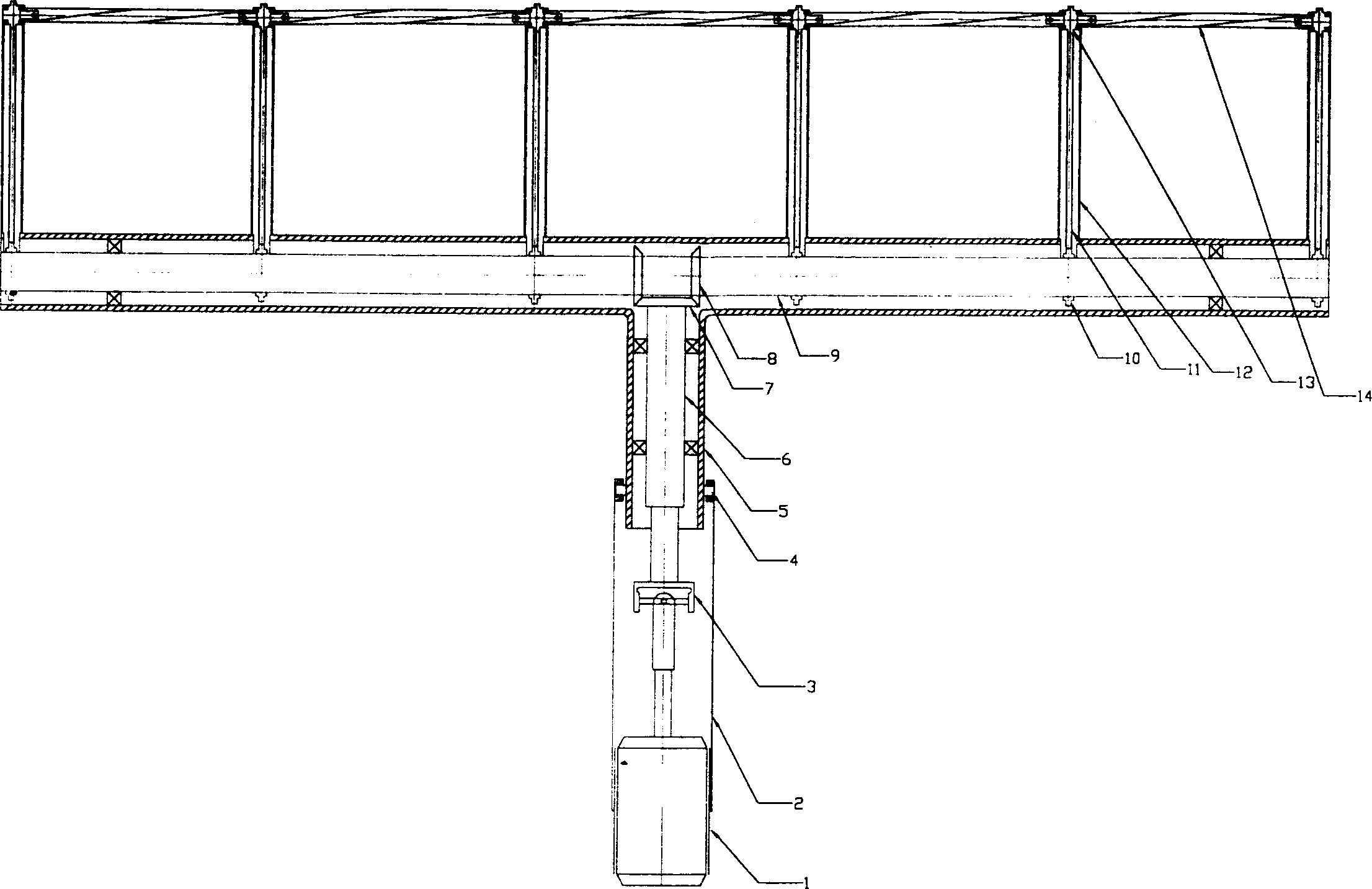

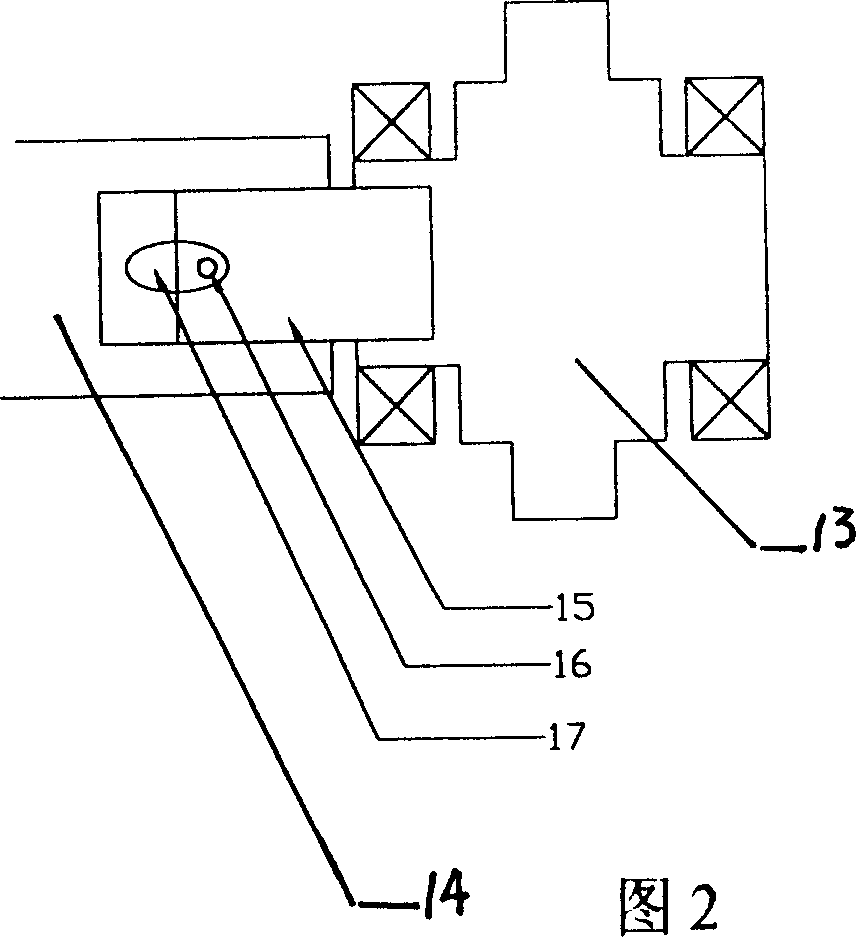

[0012] The excavation and cutting device includes a sleeve (5), a power structure, a transmission structure and a cutting structure. The power structure drives the sprocket shaft (9) to rotate through the transmission structure, and the driving sprocket (10) is connected with the chain saw (11) from Driven sprocket (13) rotates, and chain saw (11) rotates and cuts, and driven sprocket (13) and square key (15) movably cooperate to connect cutting shaft (14).

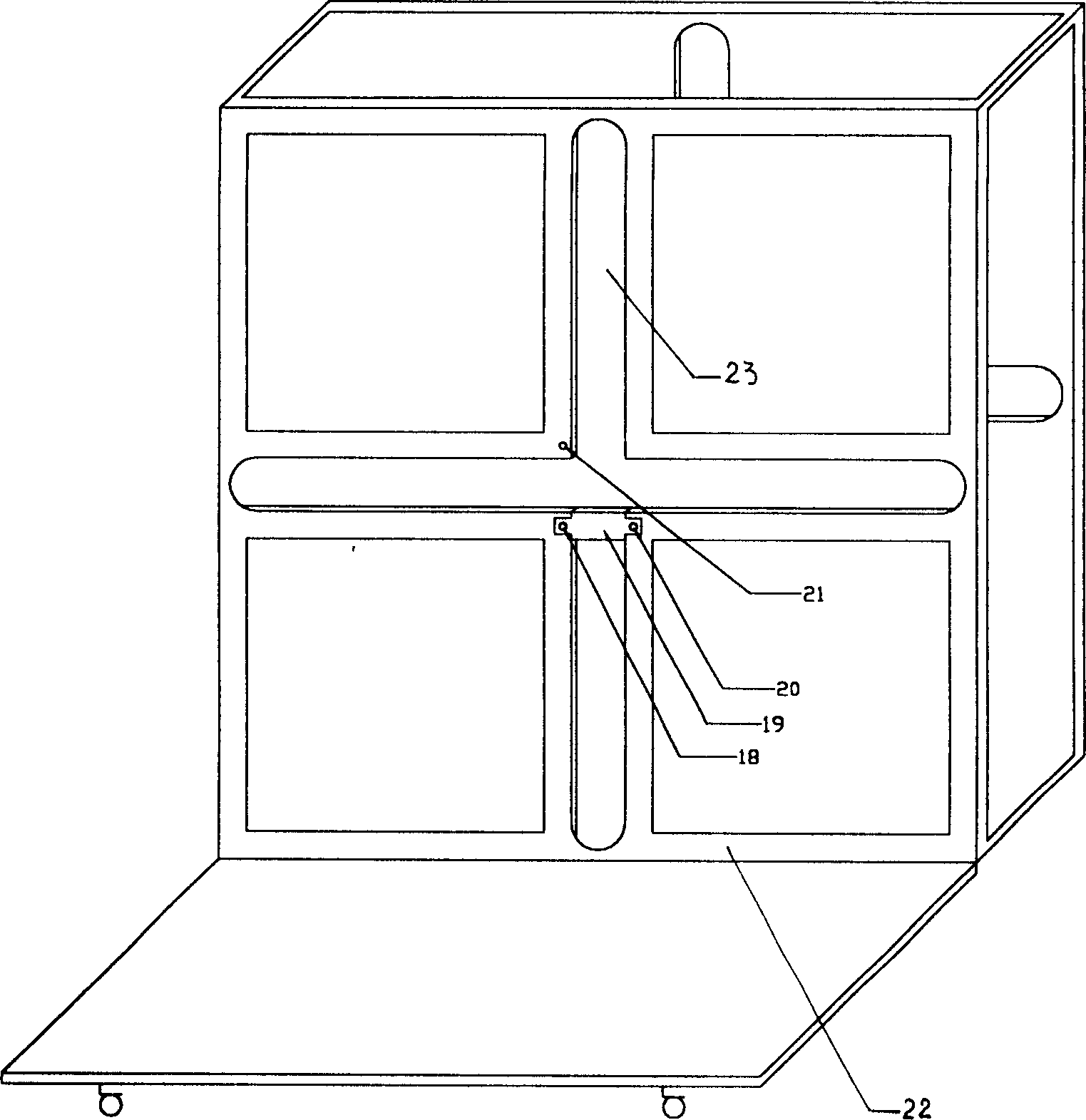

[0013] The sleeve (5) is integrally set in the orientation groove (23) of the carriage (22). The frame car (22) is provided with a switcher (19), and the switcher (19) locates the horizontal or vertical frame car orientation slot (23) of the switch frame car (22) with the switcher rotating shaft (18). Driven sprocket wheel (13) and square key (15) cooperate to connect cutting shaft (14) with square key fixed pin (16) positioning activity through square key dial hole (17). In the power structure, the rotating shaft of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com